Pole piece coating and feeding device and coating and feeding method

A coating and pole piece technology, applied in the field of pole piece coating and feeding device, can solve the problems such as difficult control of slurry composition and viscosity, complex automatic feeding machine device, easy influence on pole piece quality, etc., and achieve improvement Pole piece qualified rate, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

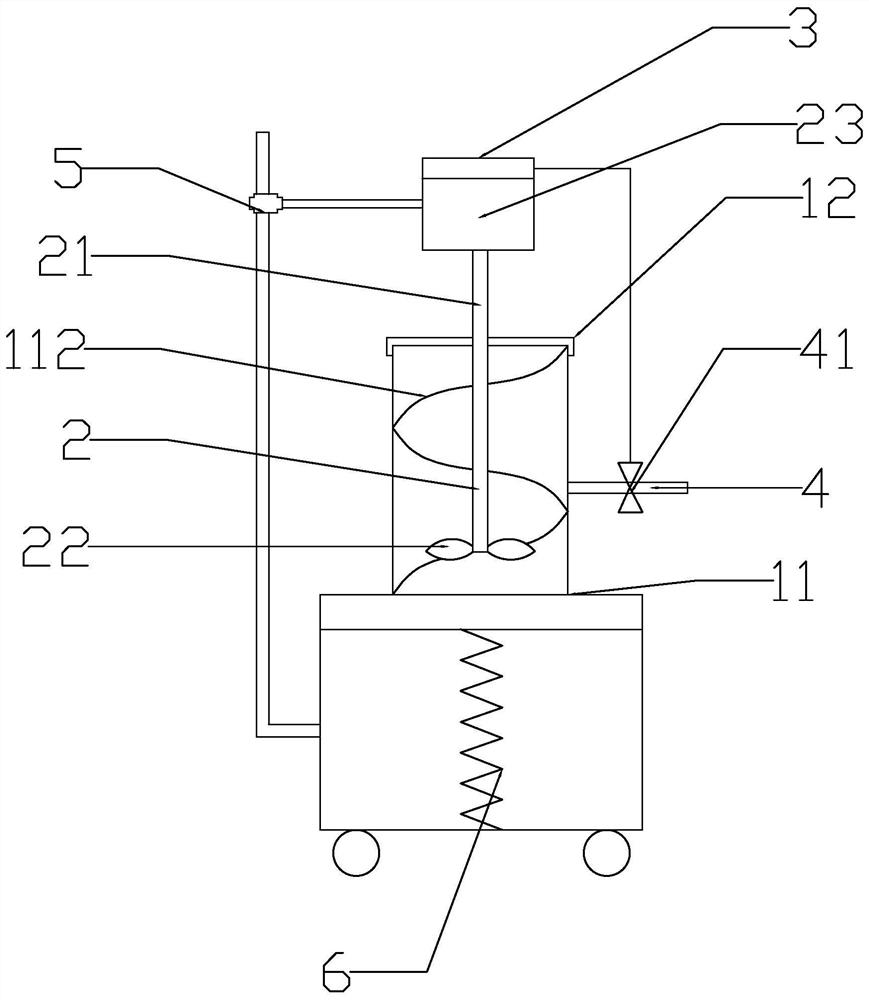

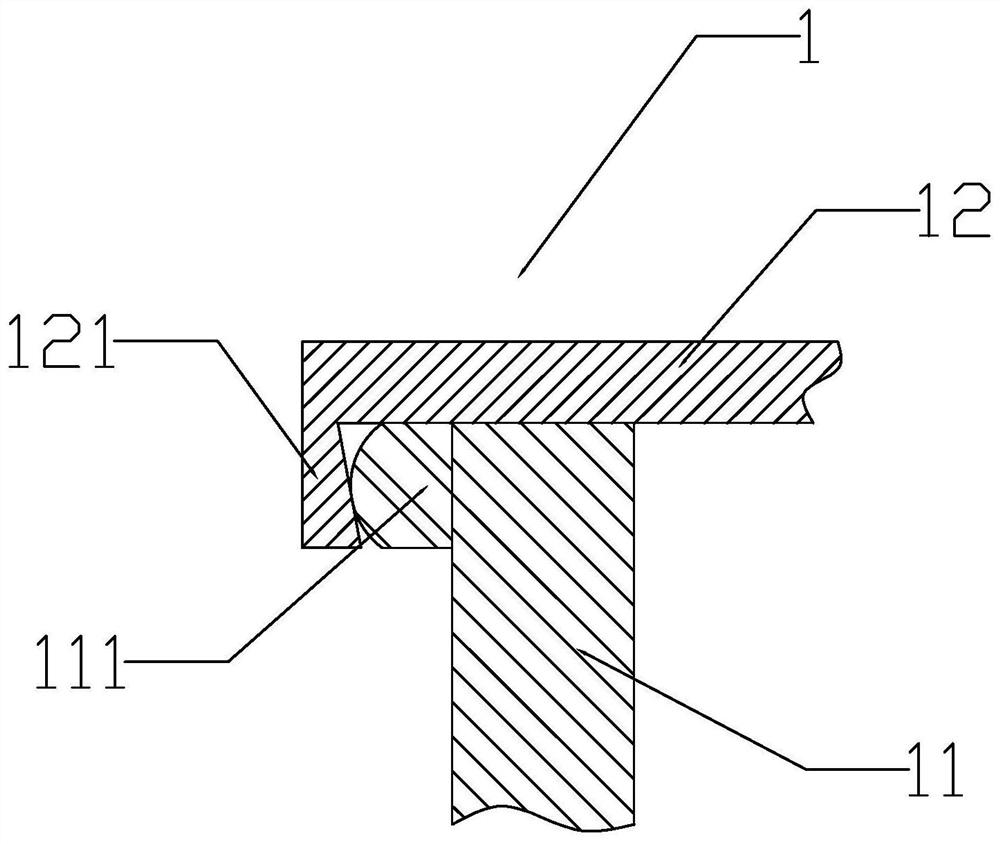

[0037] Such as figure 1 , figure 2In the shown embodiment 1, a pole piece coating and feeding device includes a storage device 1 , a stirring device 2 , a viscosity monitoring device 3 and an electric elevator 6 . The material storage device 1 is fixed on the electric elevator 6, the material storage device 1 includes a material storage tank 11 and an isolation cover 12, the side of the material storage tank 11 is connected with a discharge pipe 4, and the discharge pipe 4 is provided with a discharge valve 41, the storage A ring-shaped rubber strip 111 is provided outside the top of the bucket wall top of the barrel 11. The outer surface of the rubber strip 111 is an outwardly protruding arc surface. The outer side of the bottom surface of the isolation cover 12 is provided with a ring-shaped claw 121. The bottom of the claw 121 is wide. The top end is narrow, the inner surface of the claw 121 is attached to the outer surface of the rubber strip 111 , and the isolation cove...

Embodiment 2

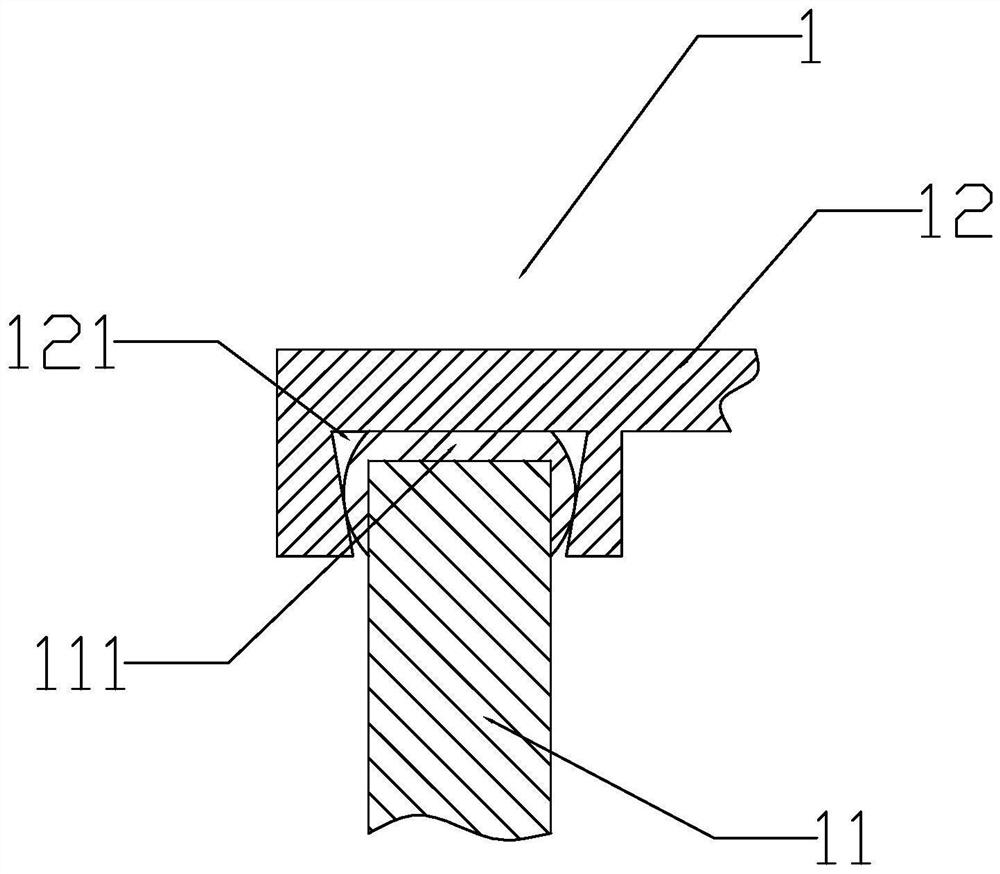

[0044] Such as figure 1 , image 3 In the shown embodiment 2, a pole piece coating and feeding device includes a storage device 1 , a stirring device 2 , a viscosity monitoring device 3 and an electric elevator 6 . Its structure is roughly the same as that of Embodiment 1, the difference is that the rubber strip 111 is U-shaped with the opening facing downwards, wrapping the inside, outside and upper side of the top of the barrel wall of the storage tank 11, and the inside surface of the rubber strip 111 is toward the storage tank. The inner side of the material barrel 11 has a protruding arc surface, the outer side is an arc surface protruding toward the outside of the material storage barrel 11, and the upper end surface is a plane. The outer side of the bottom surface of the isolation cover 12 is provided with a circle of opening downward annular draw-in groove 122, the bottom end of the draw-in groove 122 groove wall is wide, the top is narrow, the inner surface of the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com