An automatic control system and method suitable for closed-circuit cement combined grinding

An automatic control system and combined grinding technology, applied in the field of automatic control system and closed-circuit cement combined grinding, can solve the problems of low cement production efficiency, increased power consumption, and reduced equipment service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

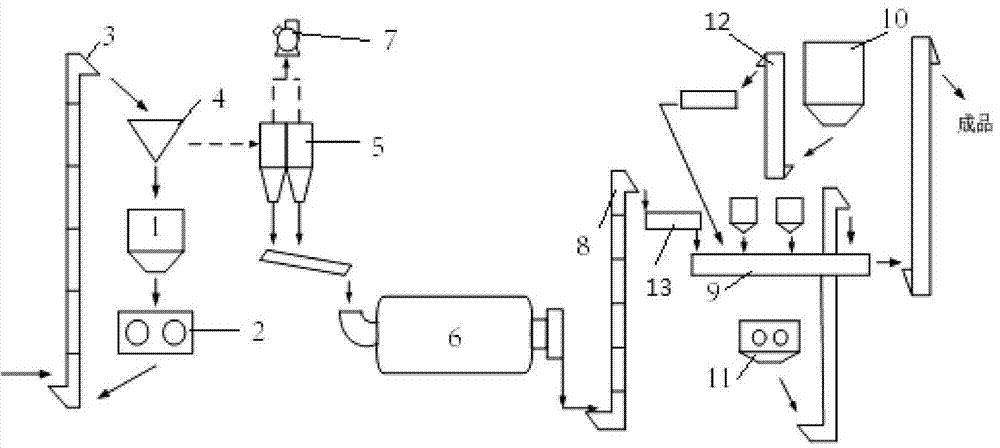

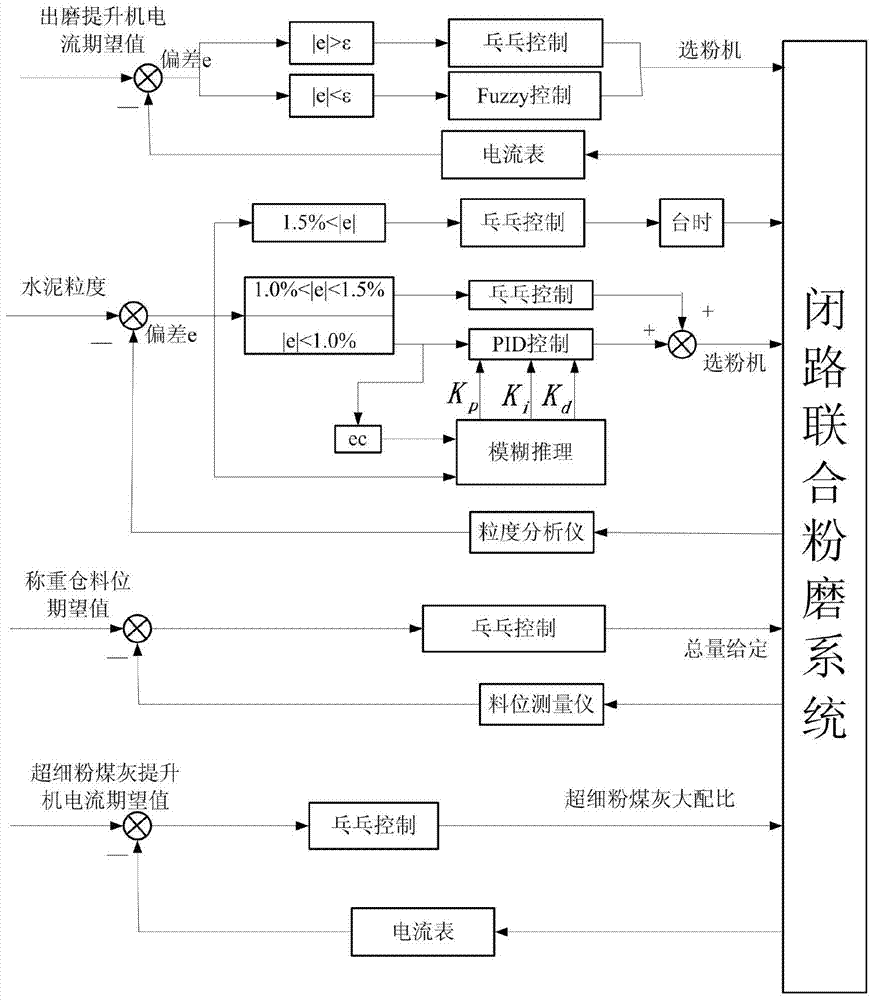

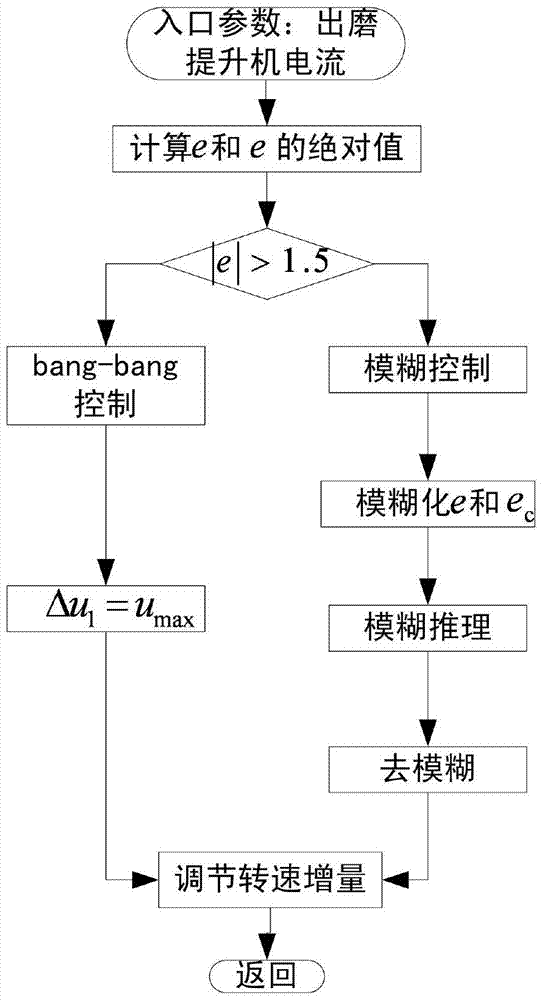

[0027] like figure 1 Shown is the closed-circuit cement combined grinding automatic control system of the present invention. First, the raw materials such as gypsum, fluorogypsum, and clinker are prepared in a certain proportion, then weighed by the weighing bin 1, and then entered into the roller press 2 for rolling. Afterwards, it is sent to the powder separator 4 for screening by the elevator 3. The qualified raw materials enter the ball mill 6 through the cyclone 5 for grinding, and the circulating fan 7 supplies air to the cyclone 5, and the unqualified raw materials need to be returned to the roller. The press 2 is rolled, and the qualified raw materials are sent to the air chute 9 by the out-grinding elevator 8, and ultra-fine fly ash and mineral powder are added in a certain proportion, and the ultra-fine fly ash passes through the ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com