Preparation method for hexagonal manganese dioxide nanosheet material and application of hexagonal manganese dioxide nanosheet material as electrode material of supercapacitor

A supercapacitor, manganese dioxide technology, applied in the field of nanomaterials and electrochemical materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

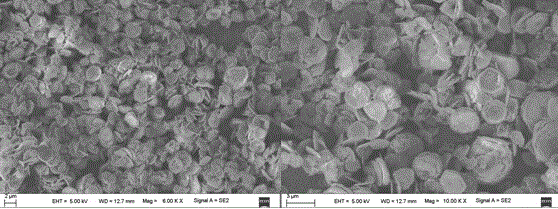

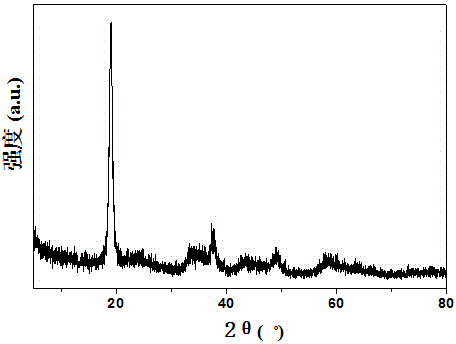

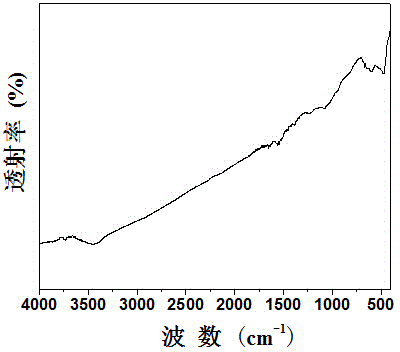

Embodiment 1

[0033] (1) Hexagonal manganese dioxide (MnO 2) Preparation of nanosheet material: 1.264g of potassium permanganate was dissolved in 100ml of distilled water to form a potassium permanganate aqueous solution; then 1g of potato starch was dispersed in 100mL of potassium permanganate aqueous solution and magnetically stirred for 5 hours to obtain a mixed solution. Then use KOH solution to adjust the pH value of the mixed solution to 9~10, move it to a high-pressure reactor, and heat it in water at 180°C for 24 hours; after cooling to room temperature, filter it with suction, and wash it repeatedly with absolute ethanol and distilled water until neutral. Vacuum drying at 60°C for 12 hours to obtain flaky hexagonal manganese dioxide;

[0034] (2) Hexagonal manganese dioxide (MnO 2 ) Preparation of nanosheet material electrode: 5.88 mg of mixed solid powder of manganese dioxide nanosheet material and acetylene black (85% and 15% by mass respectively) were uniformly dispersed in 1mL...

Embodiment 2

[0037] (1) Hexagonal manganese dioxide (MnO 2 ) Preparation of nanosheet material: 1.5g of potassium permanganate was dissolved in 100mL of distilled water to form potassium permanganate aqueous solution; then 1g of potato starch was dispersed in 100mL of potassium permanganate aqueous solution, and magnetically stirred for 6 hours to obtain a mixed solution. Then use KOH solution to adjust the pH value of the mixed solution to 9~10, move it to a high-pressure reactor, and heat it in water at 185°C for 24 hours; after cooling to room temperature, filter it with suction, and wash it repeatedly with absolute ethanol and distilled water until neutral. Vacuum drying at 60°C for 12 hours to obtain flaky hexagonal manganese dioxide;

[0038] (2) Hexagonal manganese dioxide (MnO 2 ) Preparation of nanosheet material: 5.9 mg of mixed solid powder of manganese dioxide nanosheet material and acetylene black (85% and 15% by mass, respectively) were uniformly dispersed in 1mL Nafion solu...

Embodiment 3

[0041] (1) Hexagonal manganese dioxide (MnO 2 ) Preparation of nanosheet material: Dissolve 1.6g potassium manganate in 100ml distilled water to form potassium permanganate aqueous solution; then disperse 0.8g potato starch in 100ml potassium permanganate aqueous solution, stir magnetically for 6h to obtain a mixed solution . Then use KOH solution to adjust the pH value of the mixed solution to 9~10, move it to a high-pressure reactor, and heat it in water at 185°C for 12 hours; after cooling to room temperature, filter it with suction, and wash it repeatedly with absolute ethanol and distilled water until neutral. Vacuum drying at 60°C for 12 hours to obtain flaky hexagonal manganese dioxide;

[0042] (2) Hexagonal manganese dioxide (MnO 2 ) Preparation of nanosheet material: 5.8 mg of mixed solid powder of manganese dioxide nanosheet material and acetylene black (85% and 15% by mass respectively) were uniformly dispersed in 1mL Nafion solution, ultrasonicated for 50min, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com