Preparation method and application of organic molecular non-covalent bond functionalized biomass carbon material

A technology of biomass carbon and organic molecules, applied in inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve problems such as limiting specific capacitance and energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

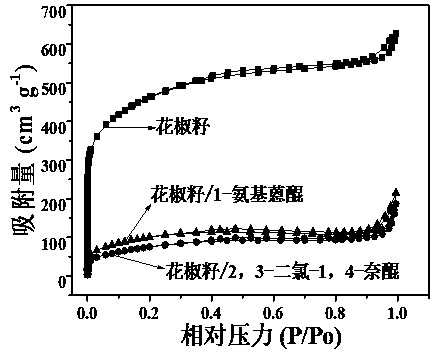

[0044] (1) Preparation of biomass porous carbon material A15: Mix 1 g of Zanthoxylum bungeanum powder and 3 g of potassium hydroxide powder, grind in a mortar for 2 h, add 20 mL of distilled water, stir for 24 h to fully react, and dry at 80 °C 12h, then in a nitrogen atmosphere at 5°C min -1 The temperature was raised to 800°C at a rate of 120 minutes, cooled to room temperature, and 1mol L -1 HCl and distilled water were washed several times, and dried at 70° C. to obtain 0.1348 g of biomass porous carbon material A15.

[0045] (2) Preparation of biomass porous carbon material electrode: 4 mg of biomass porous carbon material A15 and 0.7 mg of acetylene black (mass ratio: 85:15) were thoroughly ground in a mortar, and then the mixed powder was added to 0.4 mL of Nafion solution with a mass fraction of 0.25 wt% was ultrasonically dispersed to form a suspension; then 6 μL of the above suspension was dropped on the surface of the glassy carbon electrode with a pipette gun, and...

Embodiment 2

[0048] (1) Preparation of biomass porous carbon material A15: Mix 1 g of Zanthoxylum bungeanum seed powder and 3 g of potassium hydroxide powder, grind in a mortar for 2 h, add 20 mL of distilled water, stir for 24 h to make it fully react, and dry at 80 °C 12h, then in a nitrogen atmosphere at 5°C min -1 The temperature was raised to 800°C at a rate of 120 minutes, cooled to room temperature, and 1mol L -1 HCl and distilled water were washed several times, and dried at 70° C. to obtain 0.1348 g of biomass porous carbon material A15.

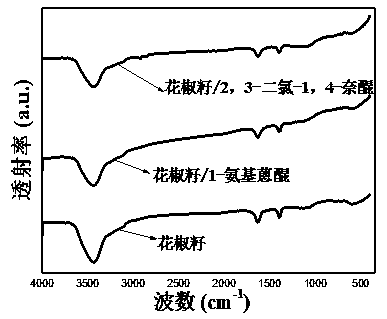

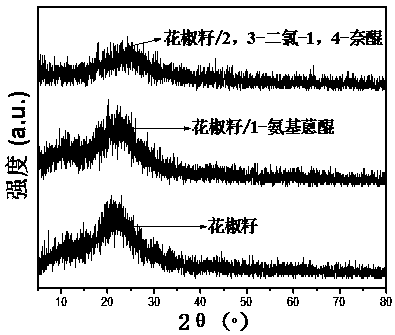

[0049] (2) Preparation of organic molecule non-covalent bond functionalized biomass carbon composite material H5: Dissolve 0.04g of 1-aminoanthraquinone in 50mL of acetone, sonicate for 30min; then add 0.05g of the biomass porous carbon material prepared above A15 (the mass ratio of A15 to 1-aminoanthraquinone is 5:4), stirred for 12 hours, and dried at 70°C to obtain H5.

[0050] (3) Preparation of organic molecule non-covalent bond functiona...

Embodiment 3

[0053] (1) Preparation of biomass porous carbon material A15: Mix 1 g of Zanthoxylum bungeanum seed powder and 3 g of potassium hydroxide powder, grind in a mortar for 2 h, add 20 mL of distilled water, stir for 24 h to make it fully react, and dry at 80 °C 12h, then in a nitrogen atmosphere at 5°C min -1 The temperature was raised to 800°C at a rate of 120 minutes, cooled to room temperature, and 1mol L -1 HCl and distilled water were washed several times, and dried at 70° C. to obtain 0.1348 g of biomass porous carbon material A15.

[0054] (2) Preparation of organic molecule non-covalent functionalized biomass carbon composite (H15): Dissolve 0.04g of 2,3-dichloro-1,4-naphthoquinone in 50mL of acetone, sonicate for 30min, and then add Mix 0.05 g of the biomass porous carbon material A15 prepared above (the mass ratio of A15 to 2,3-dichloro-1,4-naphthoquinone is 5:4), stir for 12 hours, and dry at 70°C to obtain H15.

[0055] (3) Preparation of organic molecule non-covalen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com