Preparation and application of MnO2-SnO2/graphite nanometer array composite electrode material

A technology of graphite nanosheets and composite electrodes, which is applied in the fields of hybrid capacitor electrodes, electrolytic inorganic material coating, hybrid/electric double layer capacitor manufacturing, etc., can solve problems such as no detailed reports.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

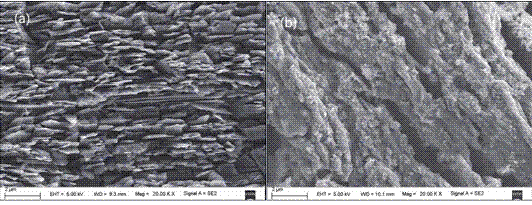

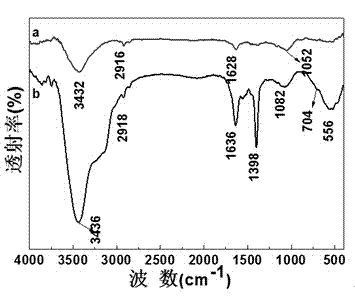

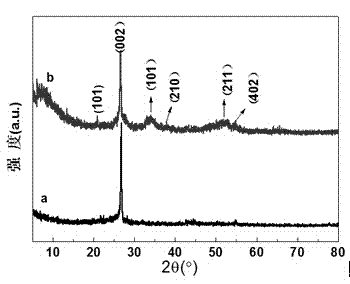

[0035] (1) Preparation of graphite nanosheet array substrate GNSA; the graphite rod was polished until the bottom surface was smooth, and after repeated ultrasonic cleaning with water, placed in 6~10mol L -1 Etched in the HCl solution for 30~50min; repeated ultrasonic cleaning with acetone and water, and dried. Configure 0.02mol·L -1 Sodium dodecylbenzene sulfonate (SDBS) was used as the electrolyte solution. Two graphite rods were placed in parallel in the electrolyte solution, and then a constant potential of 3V was applied to the two electrodes. A GNSA array was formed at the interface of the electrolyte solution; after soaking the GNSA in acetone for 24 hours, the electrode surface was taken out and washed repeatedly with high-purity water, and finally dried in an air atmosphere at 30-50°C to obtain the graphite nanosheet array substrate GNSA.

[0036] (2) MnO 2 -SnO 2 Preparation of / GNSA composite electrode: GNSA was used as the working electrode, platinum mesh and s...

Embodiment 2

[0042] (1) Preparation of graphite nanosheet array substrate GNSA; the graphite rod was polished until the bottom surface was smooth, and after repeated ultrasonic cleaning with water, placed in 7mol L -1 etched in hydrochloric acid solution for 30min; repeated ultrasonic cleaning with acetone and water, and dried. Configure 0.03mol·L -1 Sodium dodecylbenzenesulfonate (SDBS) was used as the electrolyte solution, and the cleaned two graphite rods were placed in the electrolyte solution in parallel, and then a constant positive potential of 1V was applied to the two electrodes. A GNSA array was formed at the interface of the solution; after soaking the GNSA in acetone for 24 hours, the electrode surface was taken out and repeatedly rinsed with high-purity water, and finally dried in an air atmosphere at 35°C to obtain the graphite nanosheet array substrate GNSA.

[0043] (2) MnO 2 -SnO 2 Preparation of / GNSA composite electrode: GNSA was used as the working electrode, platin...

Embodiment 3

[0049] (1) Preparation of graphite nanosheet array substrate GNSA; the graphite rod was polished until the bottom surface was smooth, and after repeated ultrasonic cleaning with water, placed in 10mol·L -1 etched in hydrochloric acid solution for 30min; repeated ultrasonic cleaning with acetone and water, and dried. Configuration 0.06mol L -1 Sodium dodecylbenzenesulfonate (SDBS) was used as the electrolyte solution, and the cleaned two graphite rods were placed in the electrolyte solution in parallel, and then a constant positive potential of 8V was applied to the two electrodes. A GNSA array is formed at the solution interface; soak the GNSA in acetone for 48 hours, take it out and rinse the electrode surface repeatedly with high-purity water, and finally dry it in an air atmosphere at 50°C to obtain the graphite nanosheet array substrate GNSA.

[0050] (2) MnO 2 -SnO 2 Preparation of / GNSA composite electrode: GNSA was used as the working electrode, platinum mesh and sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com