Preheating charging loss optimization battery pack charging method in low-temperature environment

A low-temperature environment and charging method technology, which is applied in the direction of secondary battery charging/discharging, secondary battery, electrochemical generator, etc., can solve the problem of not realizing the optimal management and control of loss, thermal runaway, and not considering energy loss and time consumption, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

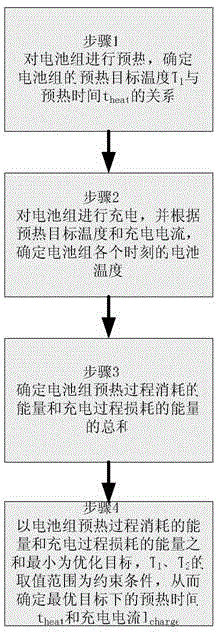

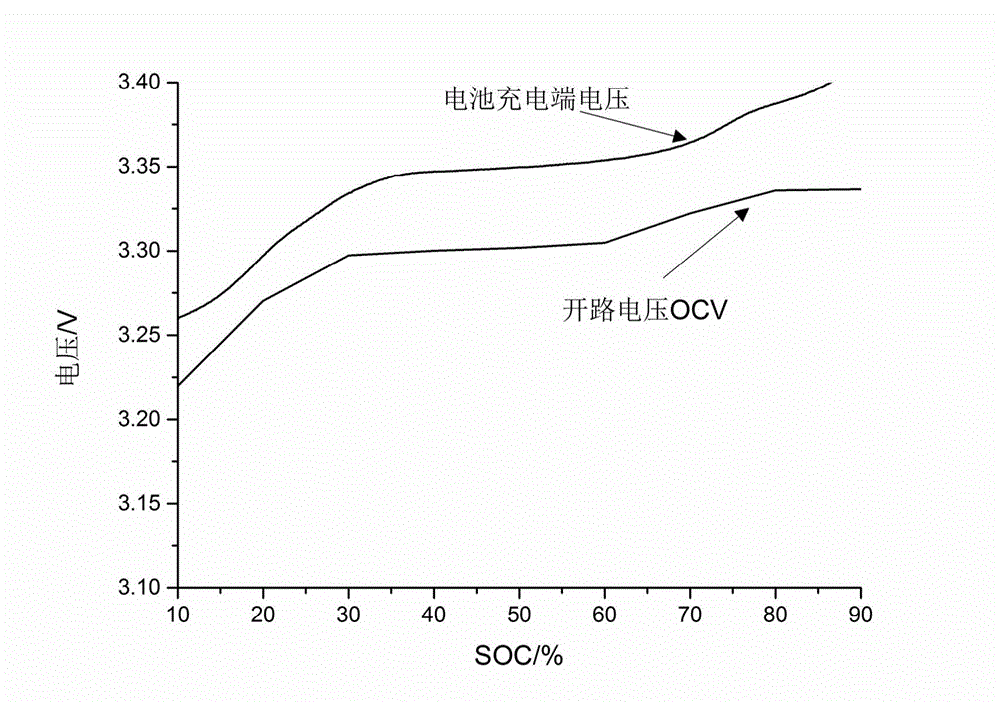

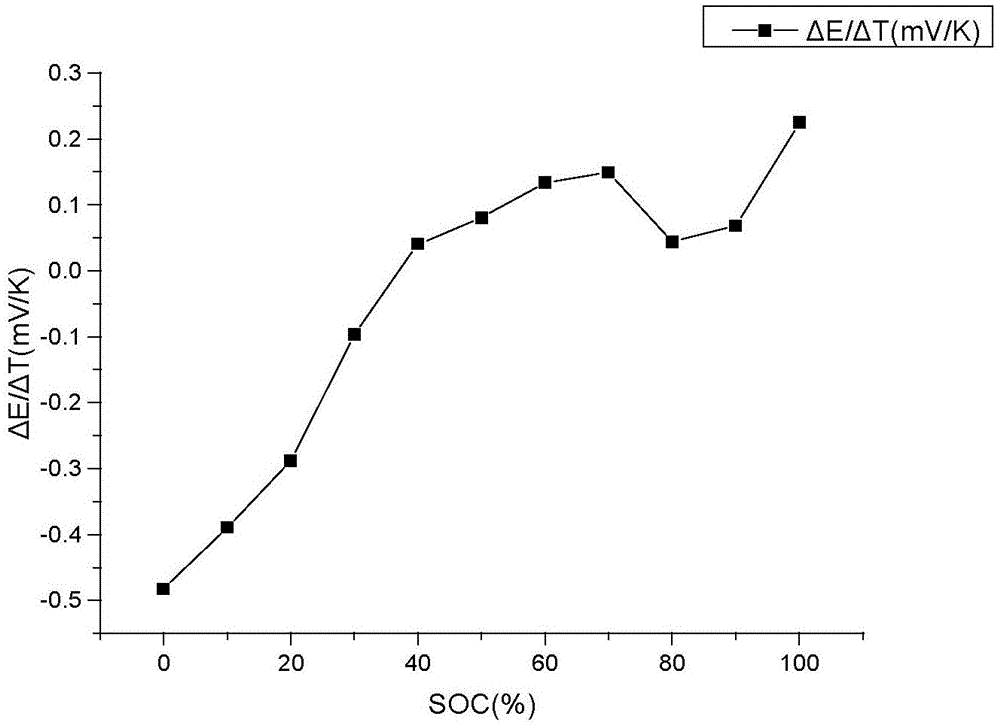

[0077] Specific implementation mode one: as Figure 1~3 As shown, the realization process of a battery pack charging method for optimizing charging loss in a low-temperature environment described in this embodiment is as follows:

[0078] A battery pack charging method for optimizing preheating charging loss in a low temperature environment, the realization process of the method is as follows:

[0079] Step 1. Preheat the battery pack and determine the warm-up target temperature T of the battery pack 1 and warm-up time t heat Relationship:

[0080] Considering that part of the preheating energy is used to heat the battery pack, and the other part is transferred to the air, the energy balance equation of the battery pack preheating stage is given as:

[0081] Pdt heat =nC battery m battery dT+C air m air dT (1-1)

[0082] Where P is the power to preheat the battery pack, n is the number of batteries in the battery pack, C battery is the specific heat capacity of a sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com