Hammer adjusting mechanism of lockstitch button holder

A technology of adjusting mechanism and buttonhole machine, which is applied to sewing machine components, tools for sewing clothes, textiles and papermaking, etc., can solve the problems of rising manufacturing costs, occupying operating space, and a large number of components, so as to reduce manufacturing costs and reduce occupied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further have a clearer and more detailed understanding and understanding of the structure, use and features of the present invention, preferred embodiments are given, and the details are as follows in conjunction with the drawings:

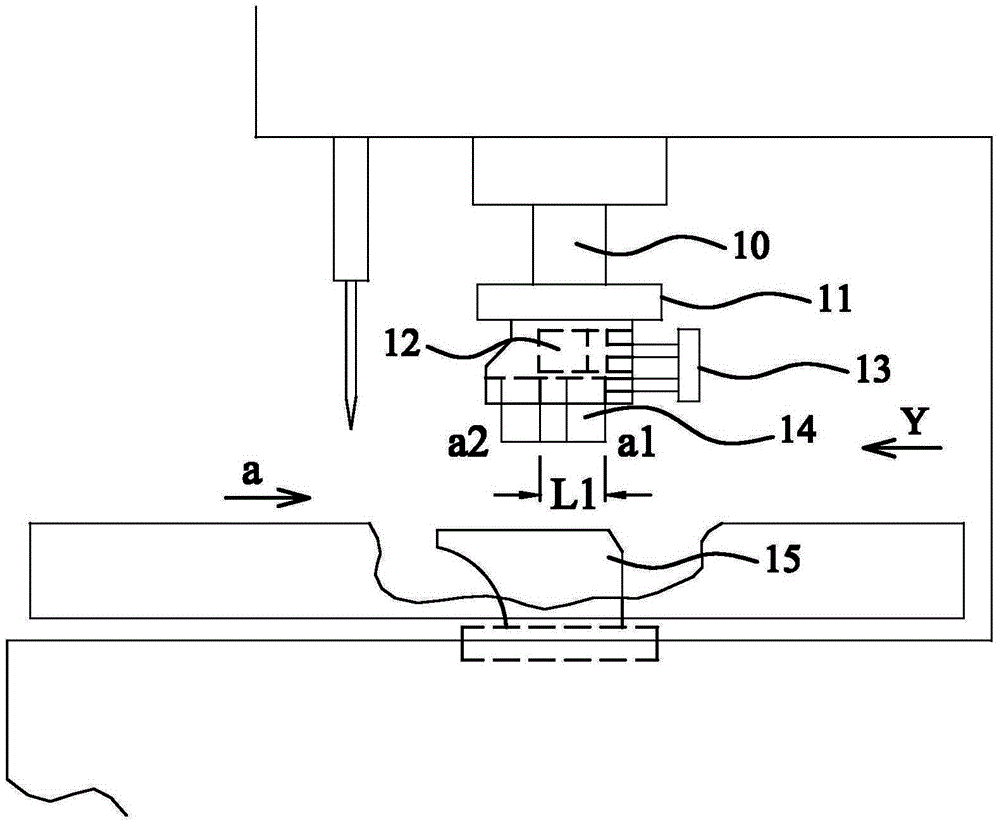

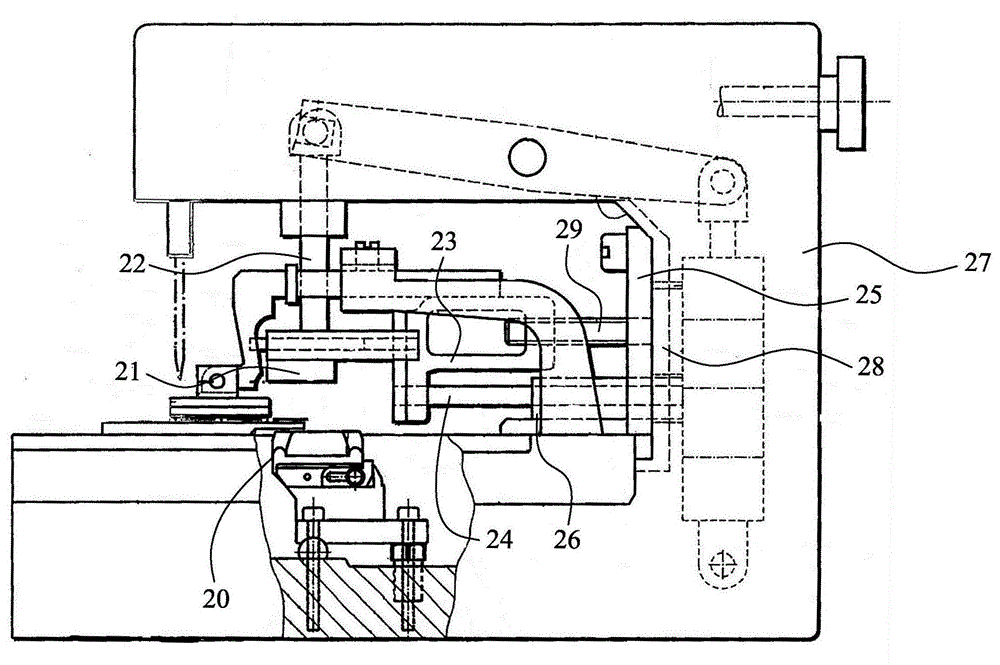

[0031] see image 3 As shown, the keyhole machine of the present invention mainly includes a headstock 30, a base 31 and a pillar 32, wherein the headstock 30 has an upper shaft 33, and one end of the upper shaft 33 is driven by a drive motor (not shown in the figure) ) to drive the rotation, the other end is provided with a needle bar 34 capable of reciprocating up and down, and the front end of the above-mentioned needle bar 34 is provided with a machine needle 35; a feeding table 36 is configured above the above-mentioned base 31, and this feeding table 36 can be The X and Y axis directions of the horizontal coordinates are shifted, and the above-mentioned feeding table 36 is provided with two pressing boards 37, and each pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com