Material for shoe upper

A technology for shoe uppers and textile materials, applied in the field of football shoes, can solve the problems of wear resistance, loss of stability and tensile strength, material deformation, etc., and achieve the effect of reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In the following, examples of embodiments and modifications of the shoe upper material of the present invention are described. Such materials are preferably used in sports shoes, especially football boots. However, as described below, it can also be used in other shoes that require both low weight and good mechanical properties, such as basketball shoes.

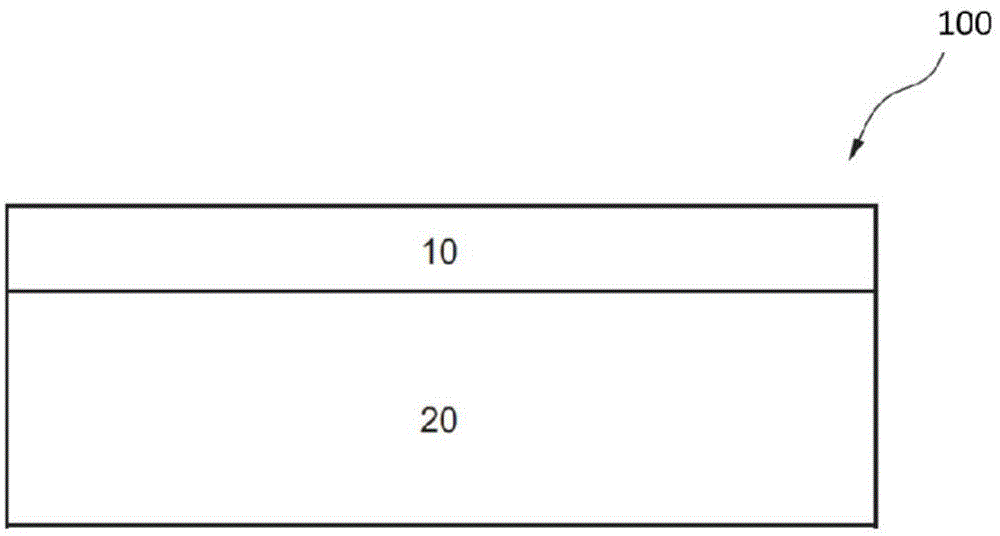

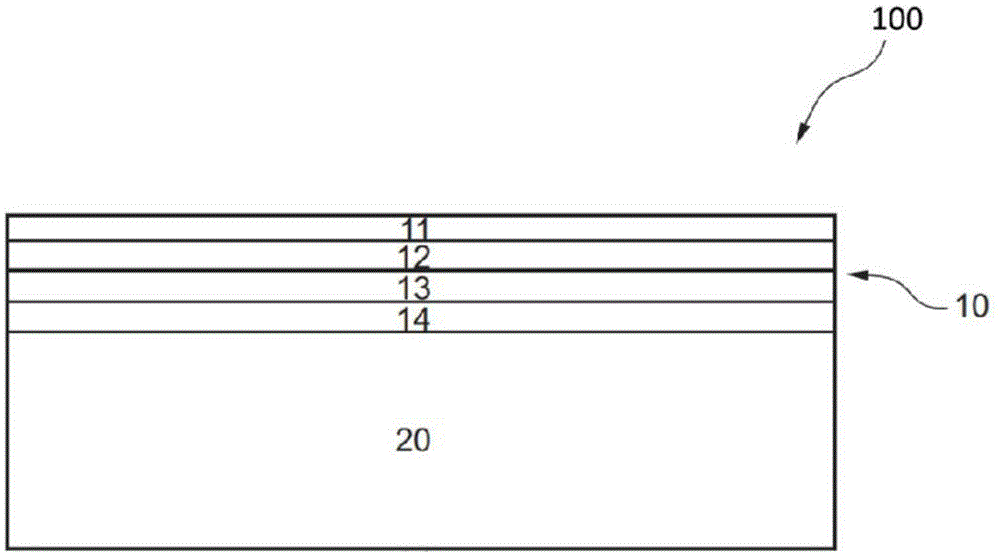

[0059] figure 1 An example of an upper material 100 is shown. figure 1 A schematic cross-sectional view of such a material 100 is shown. The figure is not to scale and is discussed in detail below. The material 100 comprises a first foil layer 10 and a textile reinforcement layer 20 laminated at least partially with the first foil layer 10 .

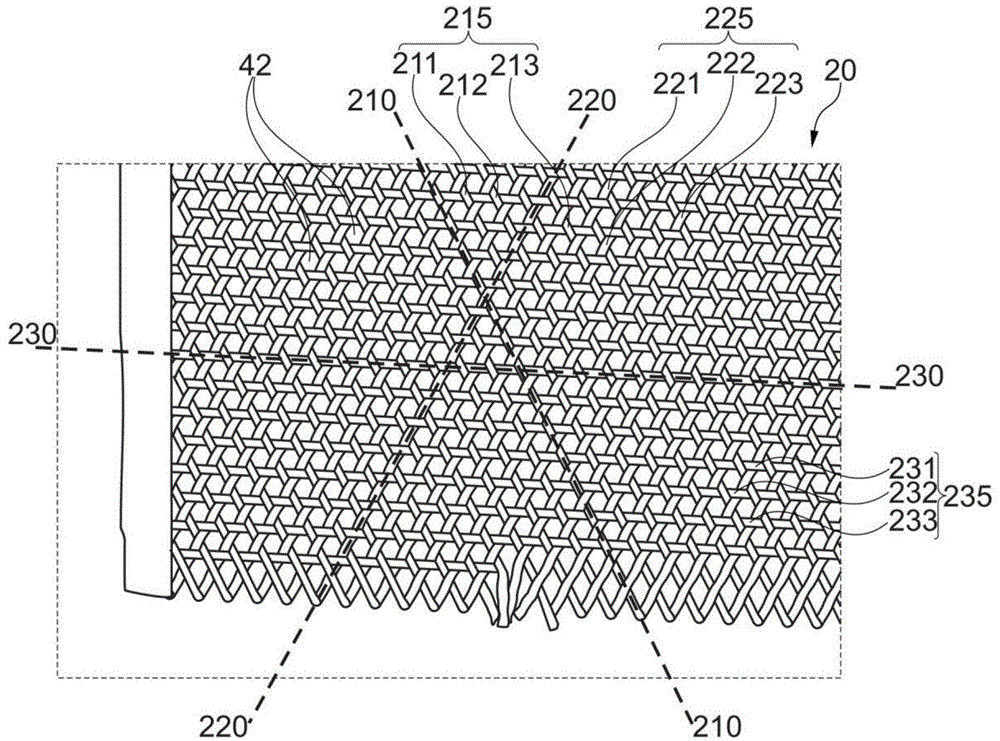

[0060] The textile reinforcement layer 20 includes a first textile material having at least three axes, each axis defining the direction of a set of substantially parallel yarn portions in the first textile material.

[0061] Preferably, the yarn portion substantially compr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com