A precision automatic batching method for LED rubber powder

An automatic batching and precision technology, applied in chemical instruments and methods, mixer accessories, weighing, etc., can solve the problem of high repetitive labor intensity, no reliability and repeatability of repetition, and poor quality of batching and other issues to achieve stable and reliable accuracy and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

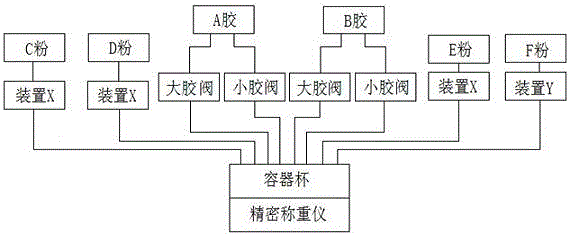

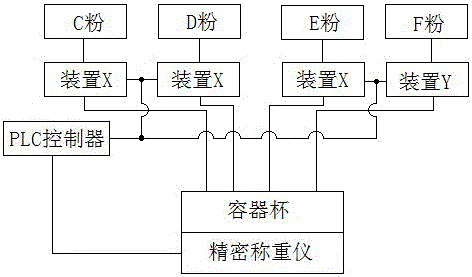

Image

Examples

Embodiment 1

[0089] Embodiment 1, as shown in the table below:

[0090]

[0091] A glue batching process, start the air compressor, so that the air pressure on the box reaches a stable value.

[0092]1) To set parameters, enter 10.0000g in the target weight column, 0.0030g in the error value column, and 150 milliseconds in the blanking time. The blanking time is the stable value selected in the test stage, that is, 150 milliseconds is the electromagnetic Once the valve is switched on and off, the weight value of glue A is relatively stable.

[0093] 2), reset and clear the precision weighing instrument;

[0094] 3), start the switch, and the device starts to run;

[0095] 4) When the large rubber valve is discharged, the time from opening to closing of the first stage control solenoid valve is 150 milliseconds, and the touch screen displays a weight of 0.2000g;

[0096] The large rubber valve discharges the material, the second stage controls the solenoid valve opening to closing tim...

Embodiment 2

[0111] Embodiment 2: C powder discharging, as shown in the table below,

[0112]

[0113] C powder 12g, use point vibration conveying device, this device is to make C powder fall into the container cup by vibration, and use the weight information fed back by the precision weighing instrument to switch the number of stages that the device operates, and its operation mode starts from the seventh stage to the end of the first paragraph.

[0114] 1) Set the parameters, the allowable error is 0.0030g, reset the precision weighing instrument, and start the device, as shown in the above table;

[0115] 2) In the seventh stage, the weight is set to 7.0000g, that is, when there is still 7.0000g of C powder left (actually 5.0000g of C powder has been collected in the container cup), switch to the sixth stage of operation;

[0116] 3) In the sixth stage, the set weight is 2.1000g, that is, when there is still 2.1000g of C powder left (9.9000g of C powder has actually been collected i...

Embodiment 3

[0119] Embodiment 3: as shown in the table below,

[0120]

[0121] F powder 18g, use the screw vibrating conveying device, this device relies on the joint operation of vibration and screw to make the F powder fall into the container cup, the screw is in the conveying pipeline, which can prevent the powder on the pipeline from clogging the pipeline, and use the precision weighing instrument to feedback The weight information, the number of segments that the switching device operates, and its operation mode is from the seventh segment to the end of the first segment.

[0122] 1) Set the parameters, the allowable error is 0.0030g, reset the precision weighing instrument, and start the device, as shown in the above table;

[0123] 2) In the seventh stage, the weight is set to 4.0000g, that is, when there is still 4.0000gF powder left (actually 14.0000gF powder has been collected in the container cup), switch to the sixth stage;

[0124] 3) In the sixth stage, the set weight i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com