Processing method of integral closed double-suction impeller of main feed water pump

A technology of main feed water pump and double suction impeller is applied in the processing field of the integral closed double suction impeller of the main feed water pump, which can solve the problems of short tool path, inability to guarantee the consistency of the flow path, overflow fluctuation, etc., so as to meet the production efficiency. , Shorten the processing time and ensure the effect of precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

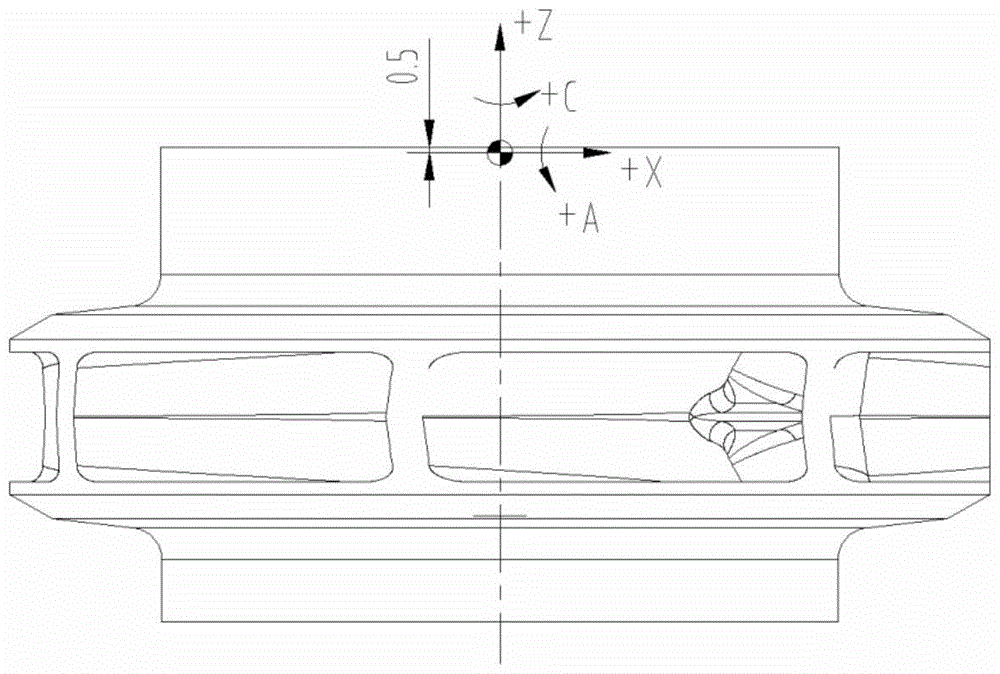

[0027] The difficulty in machining the impeller of the main feed water pump lies in the overall numerical control machining of the three-dimensional twisted blade of the impeller and the profile of the flow channel, and the wrap angle is large and the distortion is serious. It is required to meet the design requirements and ensure the hydraulic performance.

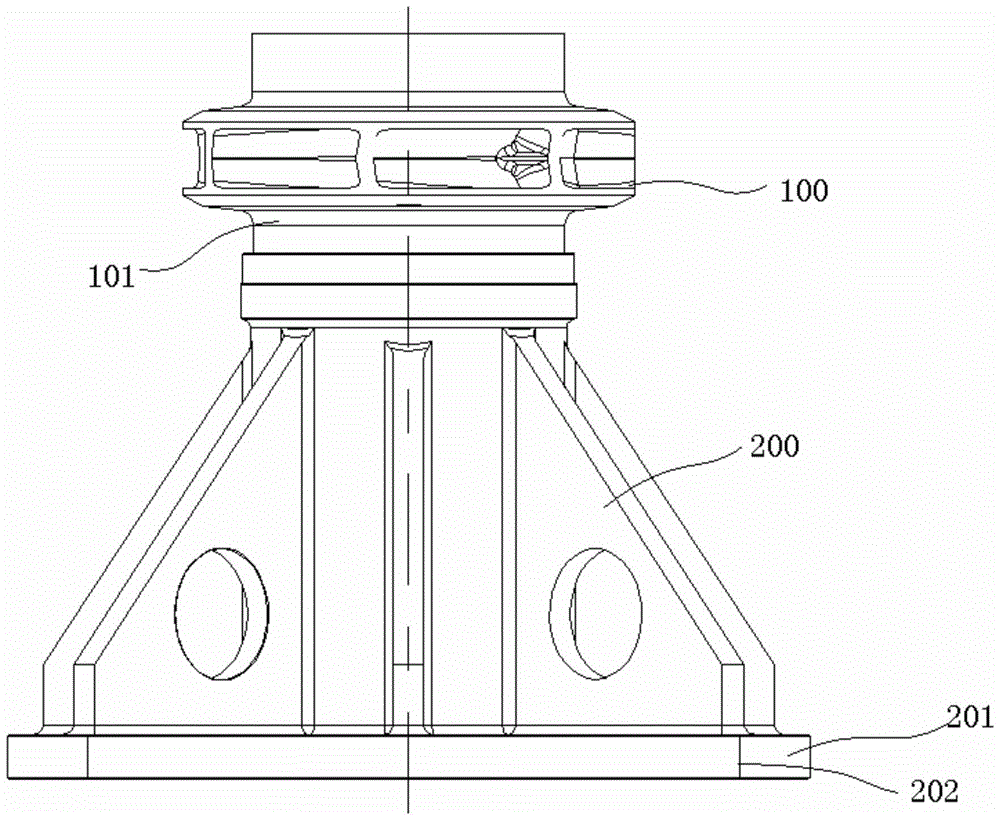

[0028] The present invention employs the following two components:

[0029] 1. TRT314 six-axis five-link machining center, equipment manufacturer: Italy JOBS company

[0030] TRT314 is a six-axis five-link machining center with a rotary table and double swing heads, which can realize X\Y\Z\A\C five-axis linkage or X\Y\Z\A\B five-axis linkage. There are various forms of movement, and the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com