High-speed thick package film bag making machine

A bag making machine and packaging film technology, applied in packaging, transportation and packaging, container manufacturing machinery, etc., can solve the problems of elongation, slow speed, and low production speed of film bags, and achieve the effect of improving the strength of ironing seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

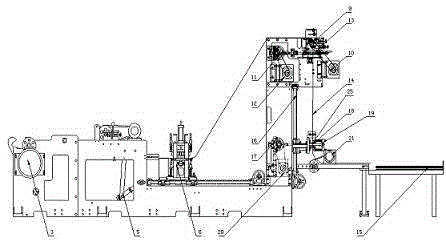

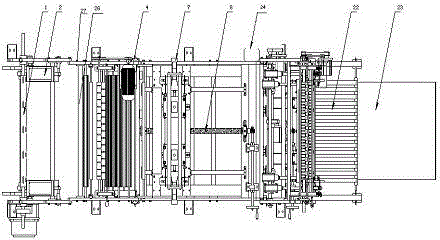

[0020] Such as figure 1 and 2 As shown, a high-speed thick packaging film bag making machine, the packaging film bag making machine includes an air expansion shaft 1, a pinch motor 4, a scalding angle mechanism 6, a cooling air mechanism 7, a scalding knife mechanism 13, a cutter mechanism 18, Water circulation cooling mechanism 19, conveying motor 21, conveying mechanism 22, programmable logic controller 24, the air expansion shaft 1 is connected to the leftmost side of the packaging film bag making machine to support the printed film bag, and the pinch motor 4 is connected to the bag making machine The film bag on the air expansion shaft 1 is transported under the working s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com