Automatic telescopic overturning accommodation ladder

An automatic retractable and gangway technology, applied to ships, cargo handling equipment, passenger processing equipment, etc., can solve problems affecting normal use, affecting efficiency, and unable to perform the telescopic lifting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

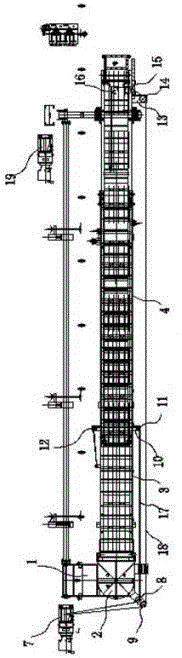

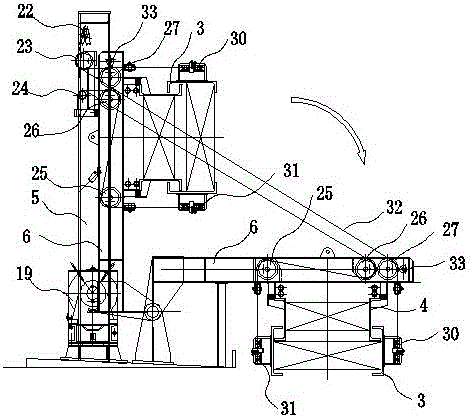

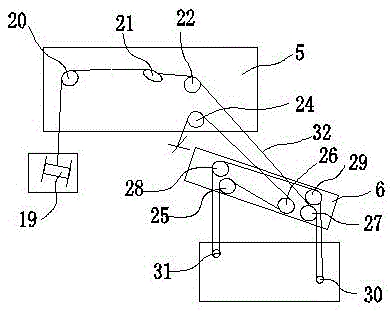

[0017] Example: such as figure 1 with Figure 5 As shown, the automatic telescopic flip gangway is installed on the hull, including: telescopic gangway, said telescopic gangway includes an upper platform frame 1 hinged on the side deck, said upper platform frame 1 is rotatably mounted with an upper platform turntable 2, An upper gangway 3 is hinged on the upper platform turntable 2, and a lower gangway 4 is slidably installed on the upper gangway 3; a telescopic drive device is arranged between the hull and the telescopic gangway; an overturning device includes a column 5, A turning arm 6 is hinged on the hull, and a rotation locking device is arranged between the turning arm 6 and the column 5, and the turning locking device locks the turning arm 6 on the column, and the rotation locking device locks the turning arm 6 on the column. The device is well known to those skilled in the art and will not be described in detail here; the turning drive device is arranged between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com