Textile reed

The invention relates to a technology of textile reed and reed beam, which is applied to textile reed. It can solve the problems that the reed cannot meet the requirements and achieve the effect of improving production quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

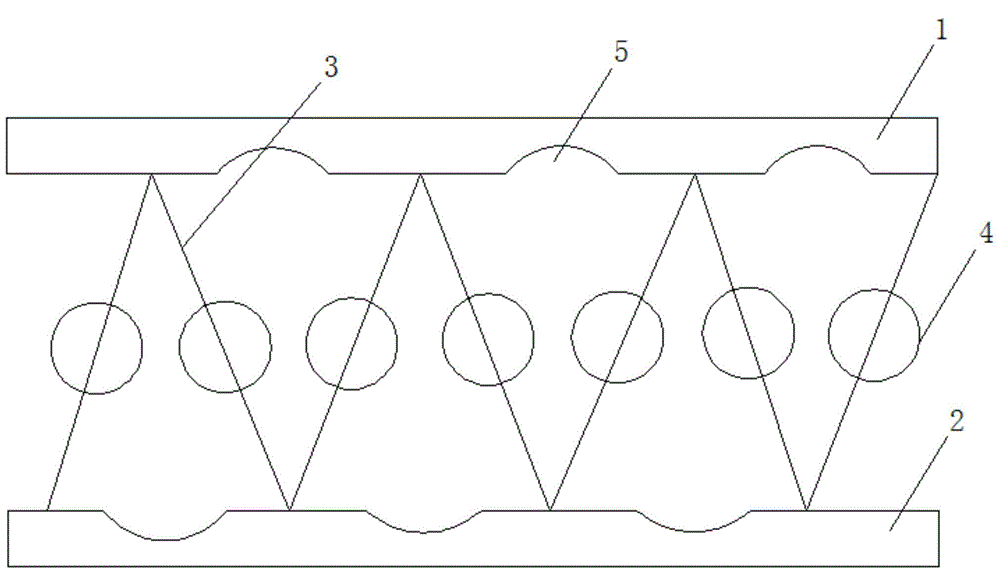

[0011] like figure 1 As shown, the textile reed includes an upper reed beam 1 and a lower reed beam 2, and a sheet-shaped reed tooth 3 is arranged between the upper reed beam 1 and the lower reed beam 2, and the reed teeth 3 are connected end to end to form a tooth shape. The middle of the reed teeth 3 is provided with a limiting edge 4, and the upper reed beam and the lower reed beam between the tooth feet of the two reed teeth are provided with a yarn relief part 5.

[0012] Wherein, the 6 pieces of the yarn relief parts are arc-shaped pits.

[0013] Wherein, the limiting edge 4 is a cylindrical limiting edge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com