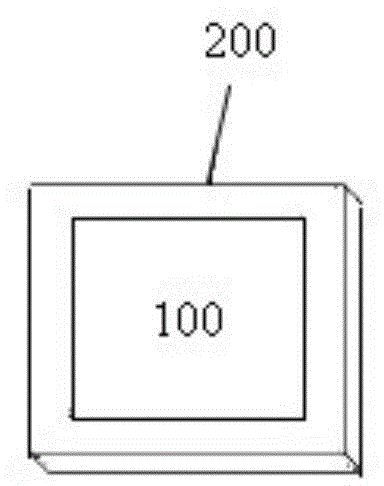

Array crystal module and machining method thereof

A processing method and crystal technology applied in the field of positron emission tomography equipment to achieve high-precision cutting and processing, ensure sensitivity and energy information acquisition accuracy, and optimize system performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

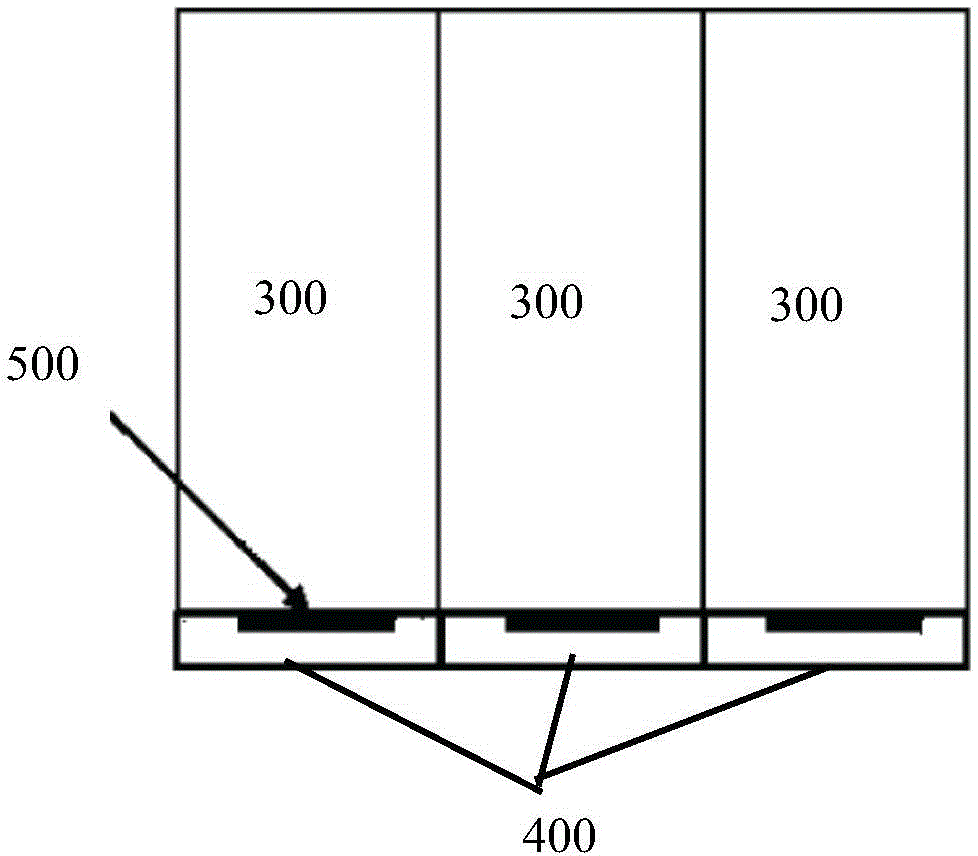

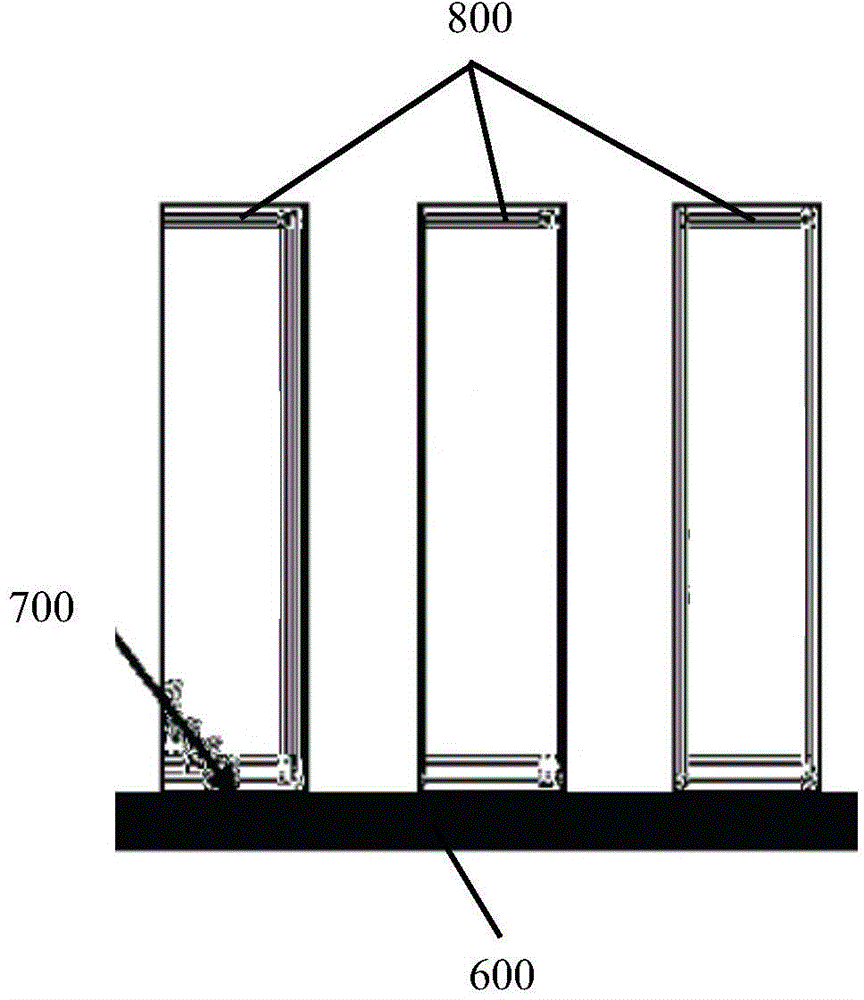

Embodiment 1

[0112] Design of a clinical PET detector using an optoelectronic device package with a surface area of 4x4mm 2 , the effective working area is 3x3mm 2, the predetermined detector is for the purpose of pursuing high temporal resolution. At present, the commonly used LYSO crystals used in commercial clinical PET usually have a thickness between 20 and 35 mm. If the crystal is too small, the sensitivity is too low to meet the detection requirements. If the crystal is too large, the thickness of the crystal will lead to excessive transmission loss of visible light photons in the crystal. The time resolution will decrease. Here, because the detector pursues high time performance, the overall thickness of the crystal is set to 20mm-22mm. At the same time, in order to ensure the sensitivity of the whole crystal to 511KeV (ray energy that PET needs to detect) rays, the thickness of the right square prism is generally set at 10-17mm. Then the thickness of the conical pedestal part ...

Embodiment 2

[0114] Design a nuclear radiation detector using an optoelectronic device package with a surface area of 6x6mm 2 , the effective working area is 3x3mm 2 , the predetermined detector pursues high sensitivity. In order to improve the detection efficiency of the detector for high-energy rays, the total thickness of the crystal is set to 38-40 mm, and the thickness of the right square prism is set to 30-35 mm. In the same way, it can be calculated that the inclination angle is between 17 degrees and 45 degrees.

[0115] From this, it can be deduced that the characteristics of optoelectronic devices affect the crystal inclination angle and the thickness of the right quadrangular prism:

[0116] The smaller the ratio of the effective detection area of the optoelectronic device to its packaging area, the larger the crystal inclination angle will be. The thickness of the right square prism = the total thickness of the crystal - the thickness of the conical truncated part, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com