Patents

Literature

38results about How to "Increase the number of photons" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

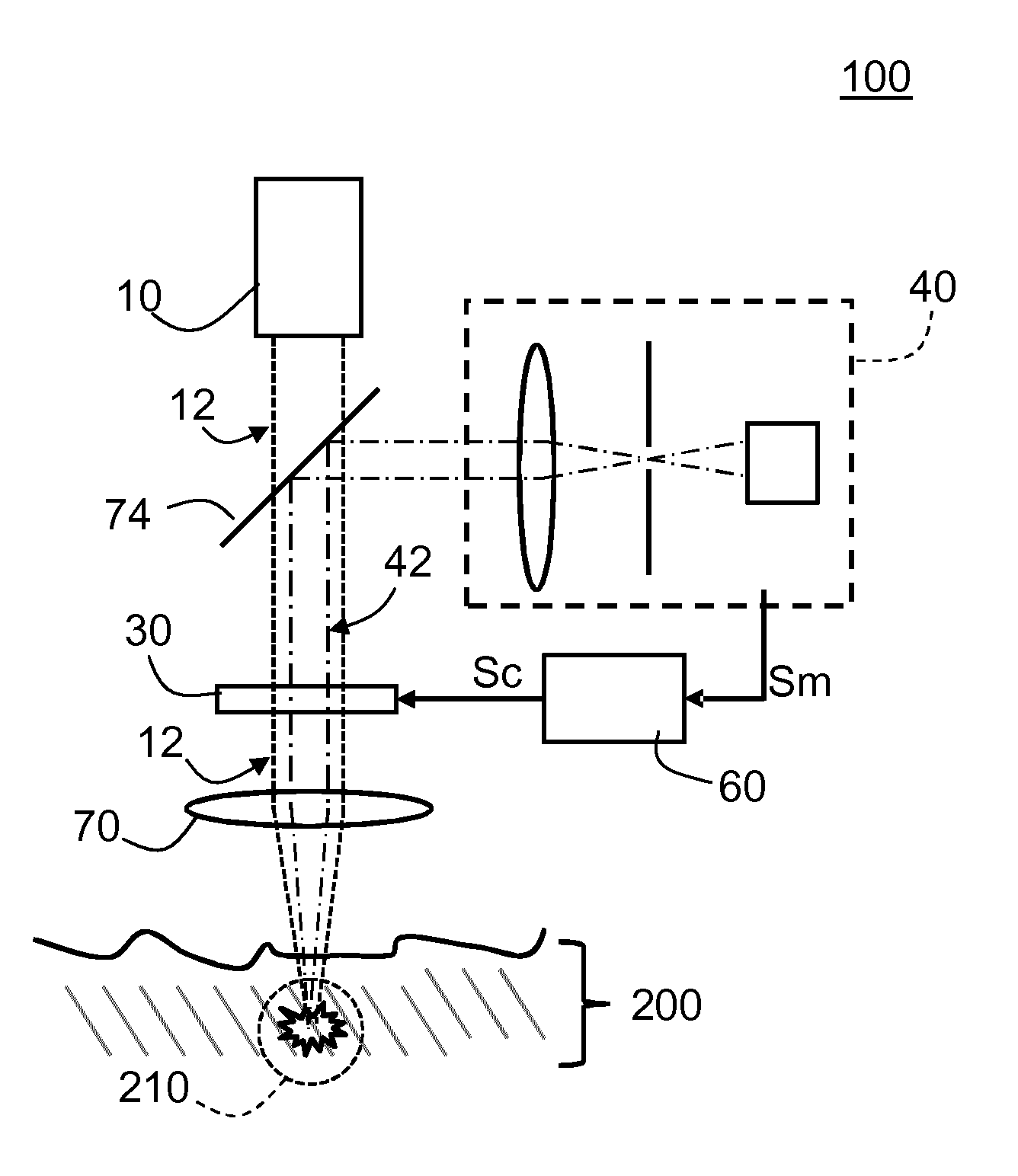

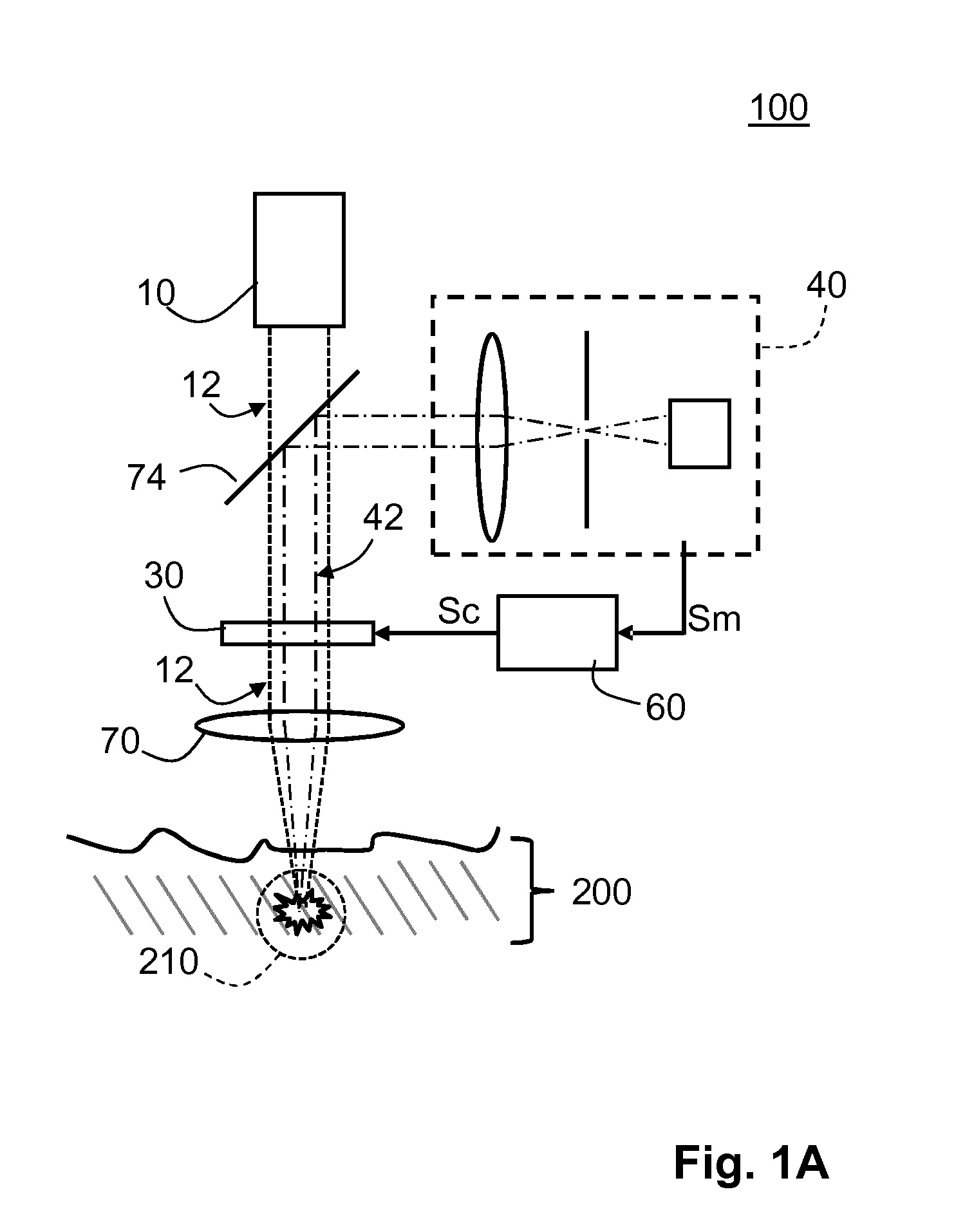

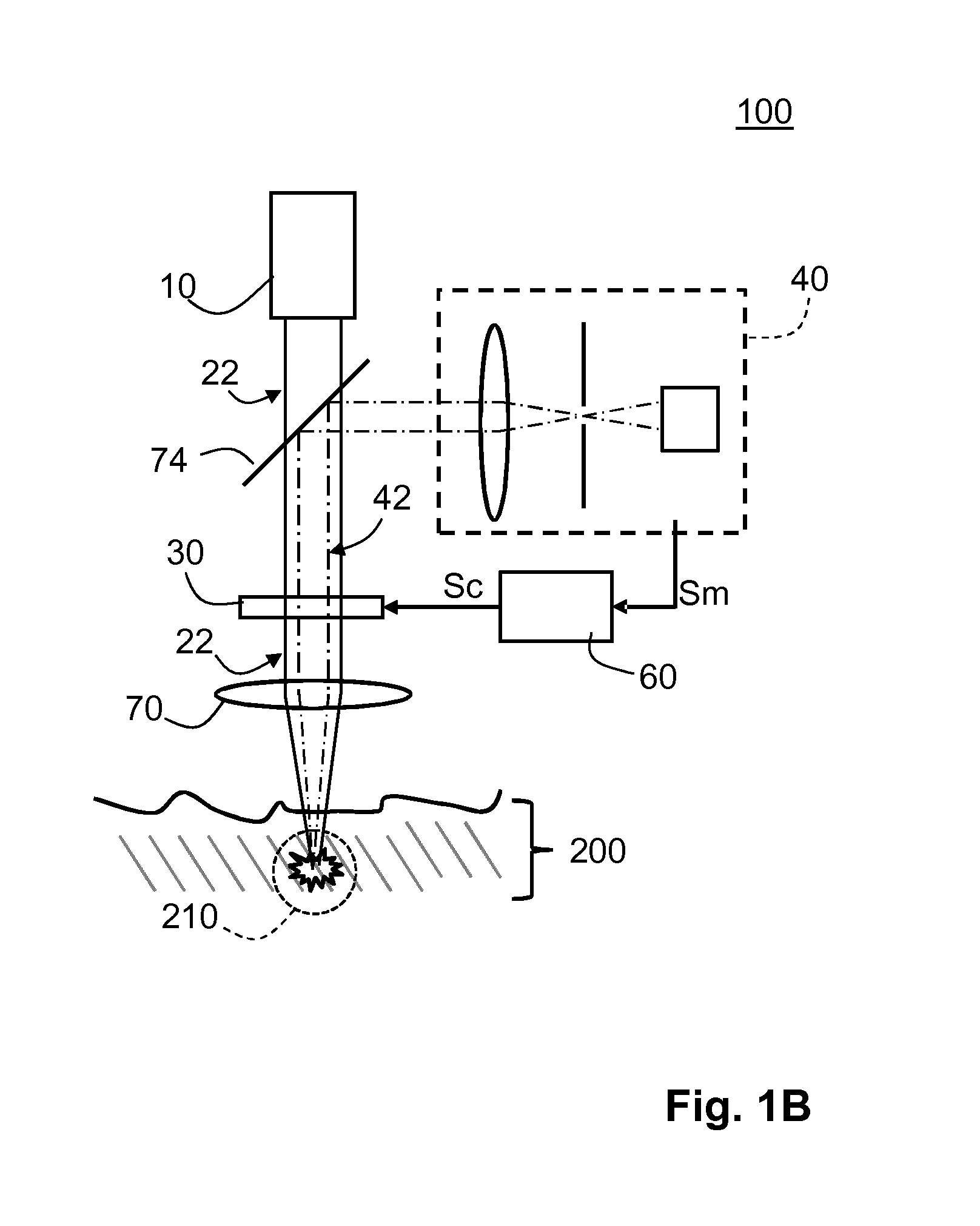

Skin Treatment Device for Multi-Photon Based Skin Treatment

ActiveUS20160249982A1Reduce light intensityIncrease the number of photonsSurgical instrument detailsLight therapySkin treatmentsNon invasive

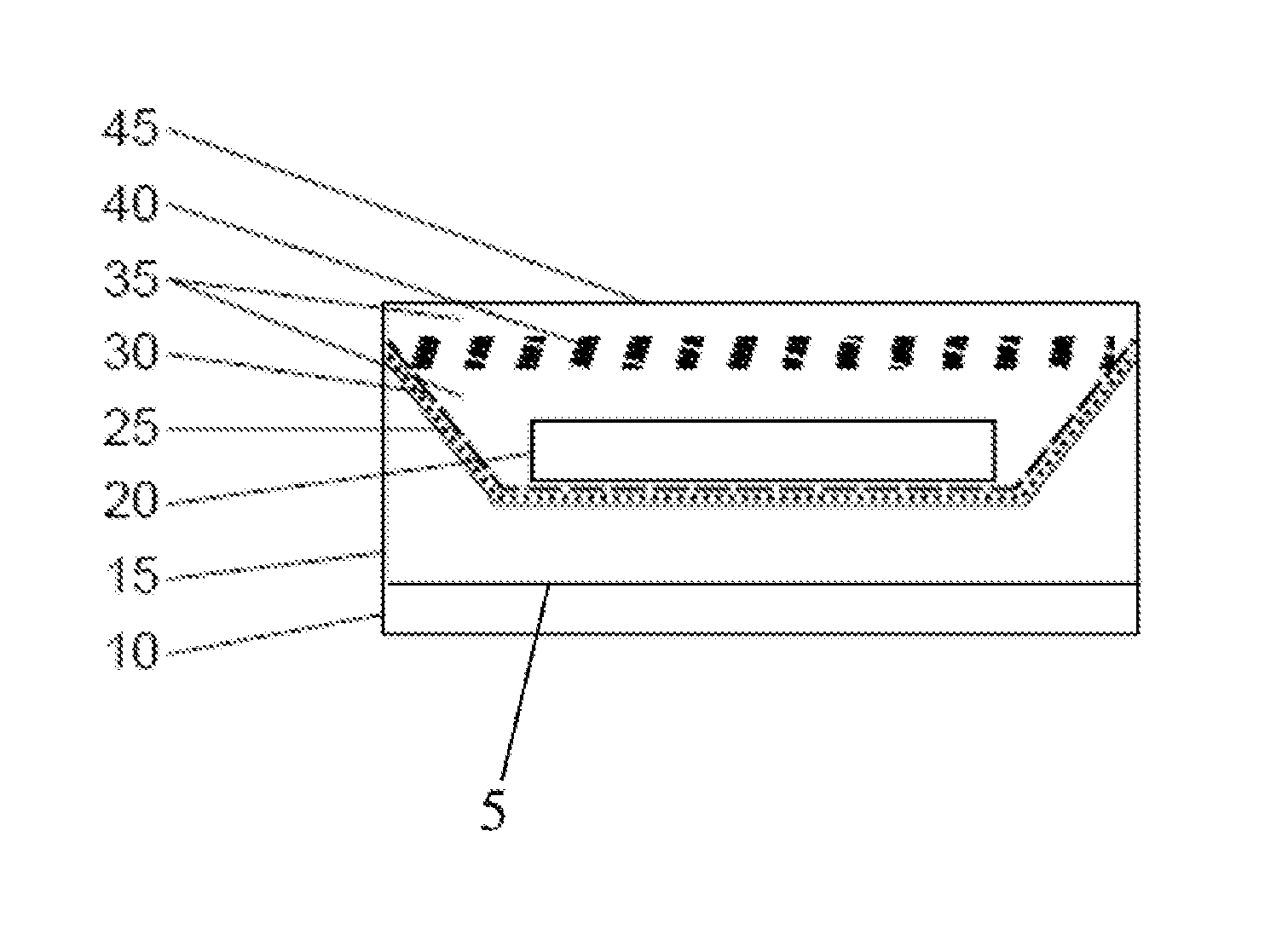

The invention provides a non-invasive skin treatment device (100) comprising: a light source (10) constructed and configured for generating linearly polarized probe light (12) and linearly polarized treatment light (22), a polarization modulator (30) constructed and configured for controlling a polarization direction of the probe light and a polarization direction of the treatment light, a polarization sensitive sensor (40) constructed and configured for sensing a level of depolarization of the probe light by sensing an intensity of back-scattered probe light (42) from the target position (210) in a predefined polarization direction of the polarization sensitive sensor, and a controller (60) being configured for scanning the polarization direction of the probe light over a predefined range while receiving the measurement signal (Sm) and for selecting an optimum polarization (P1) direction for which the depolarization of the probe light is at a minimum. The invention further provides a computer program product for controlling the skin treatment device.

Owner:KONINKLJIJKE PHILIPS NV

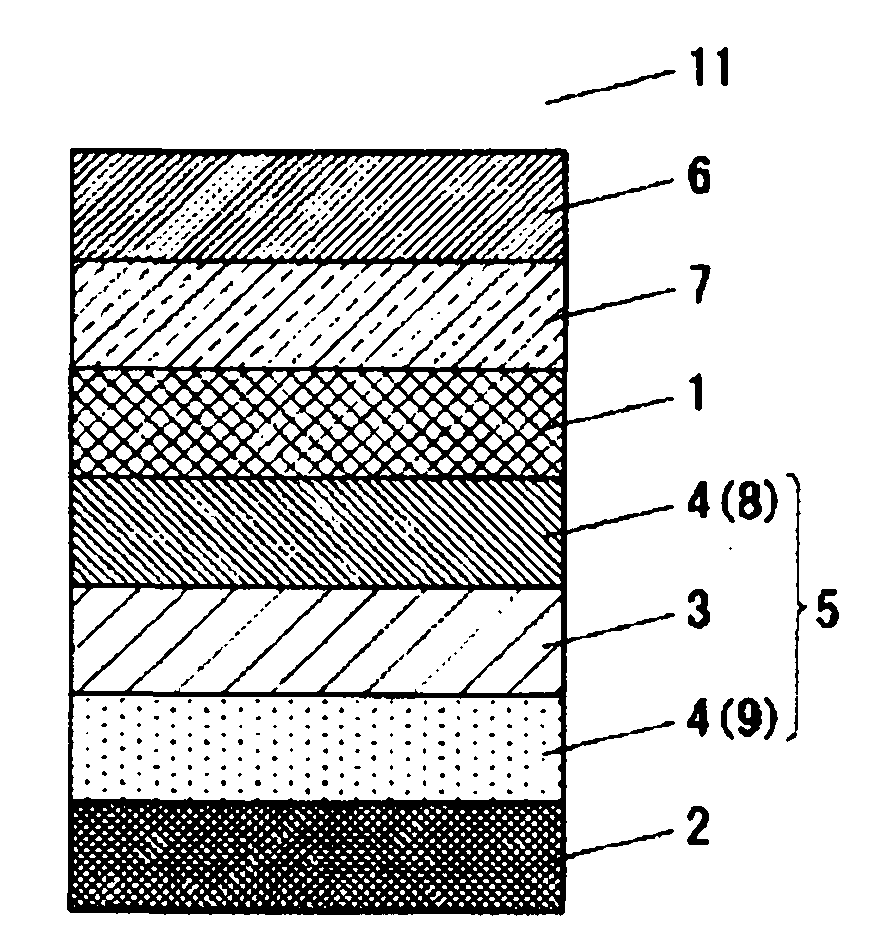

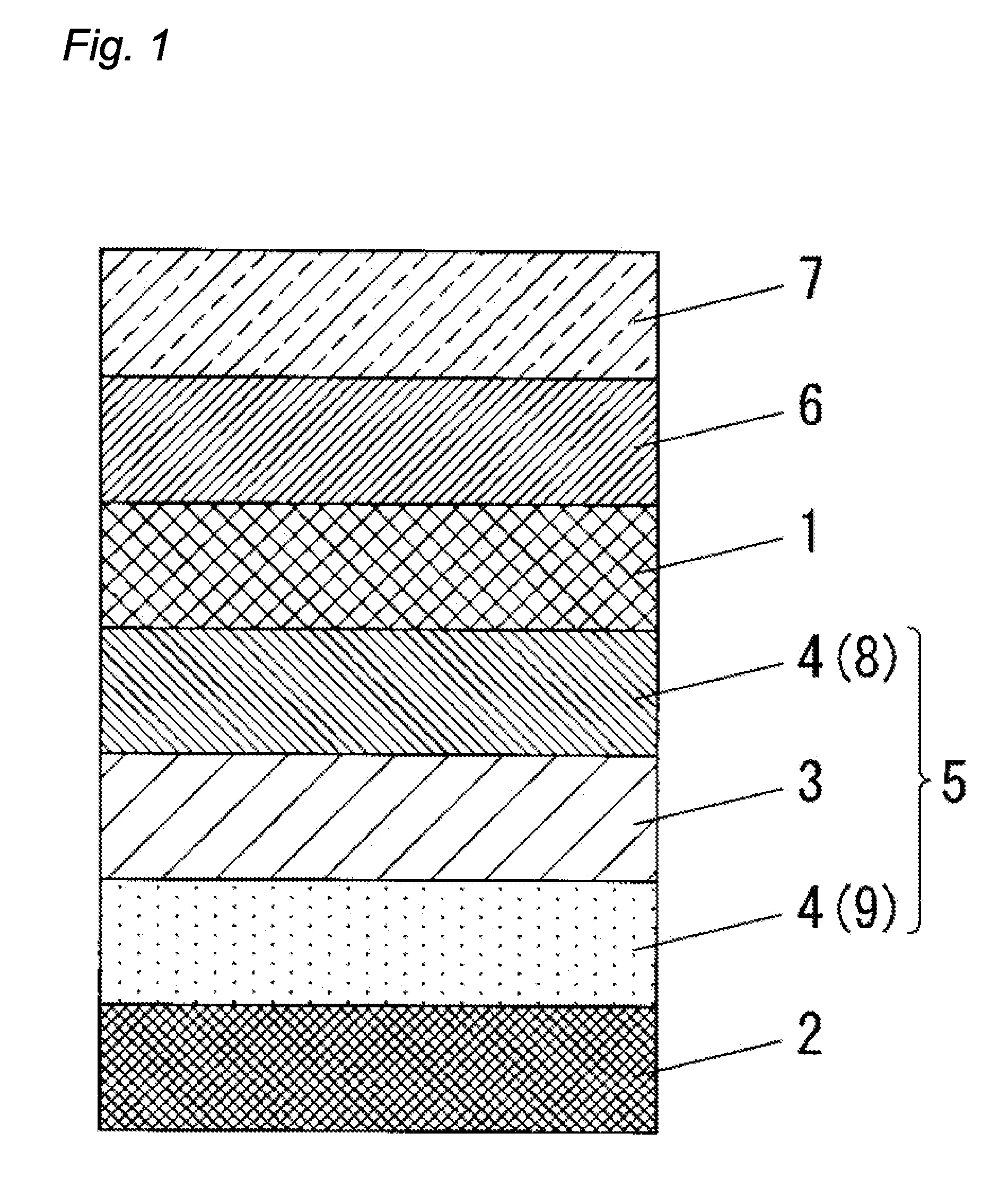

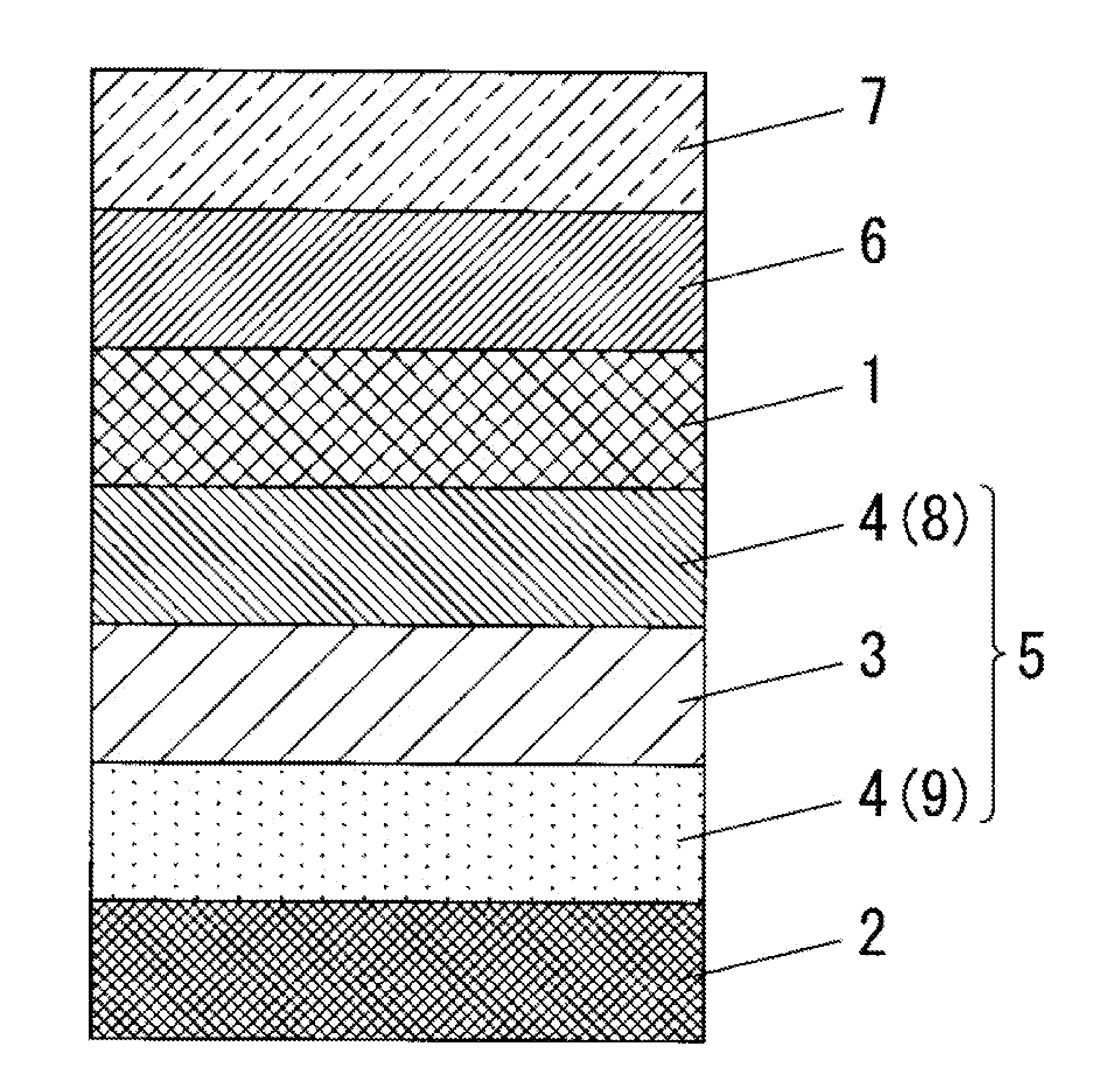

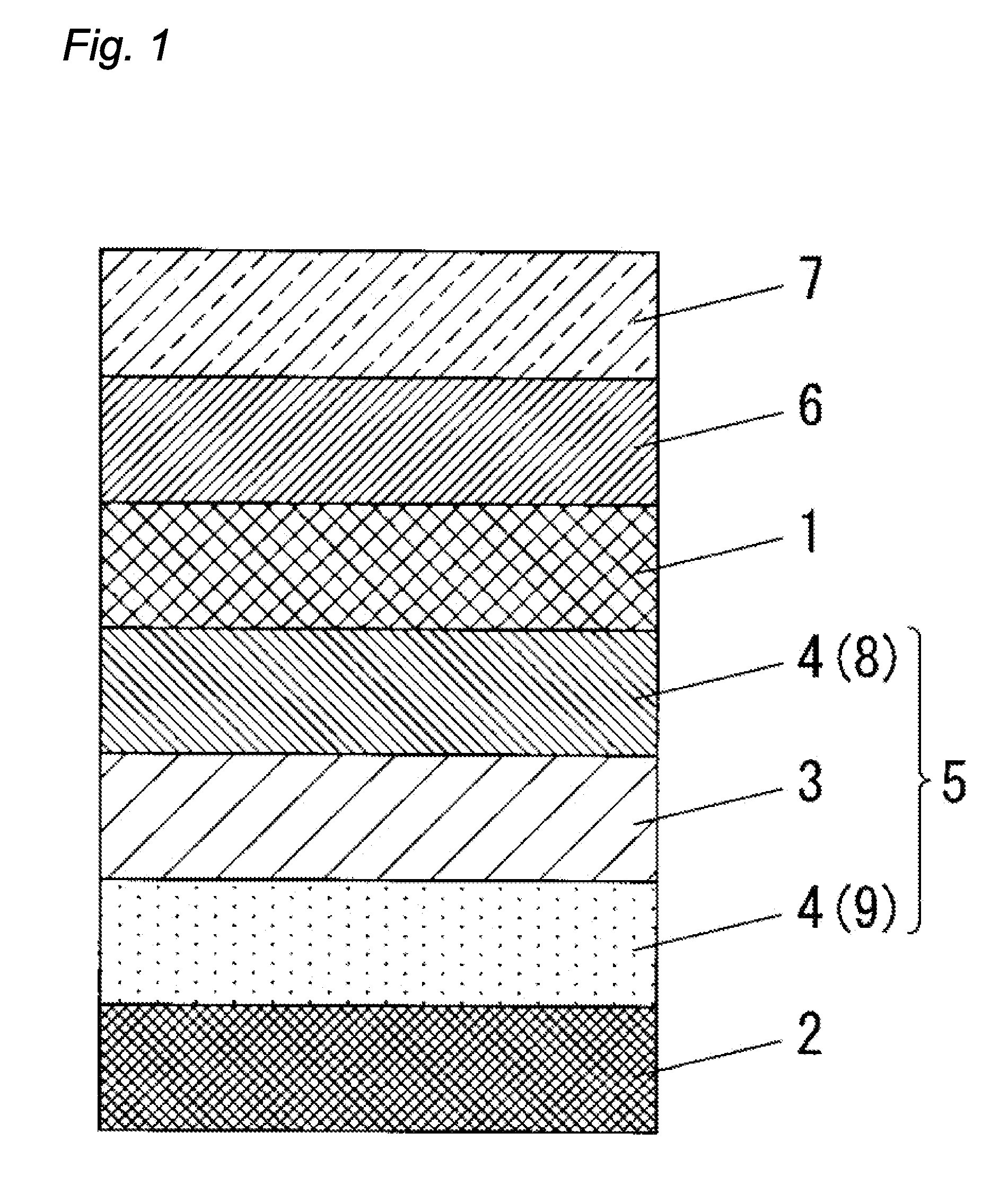

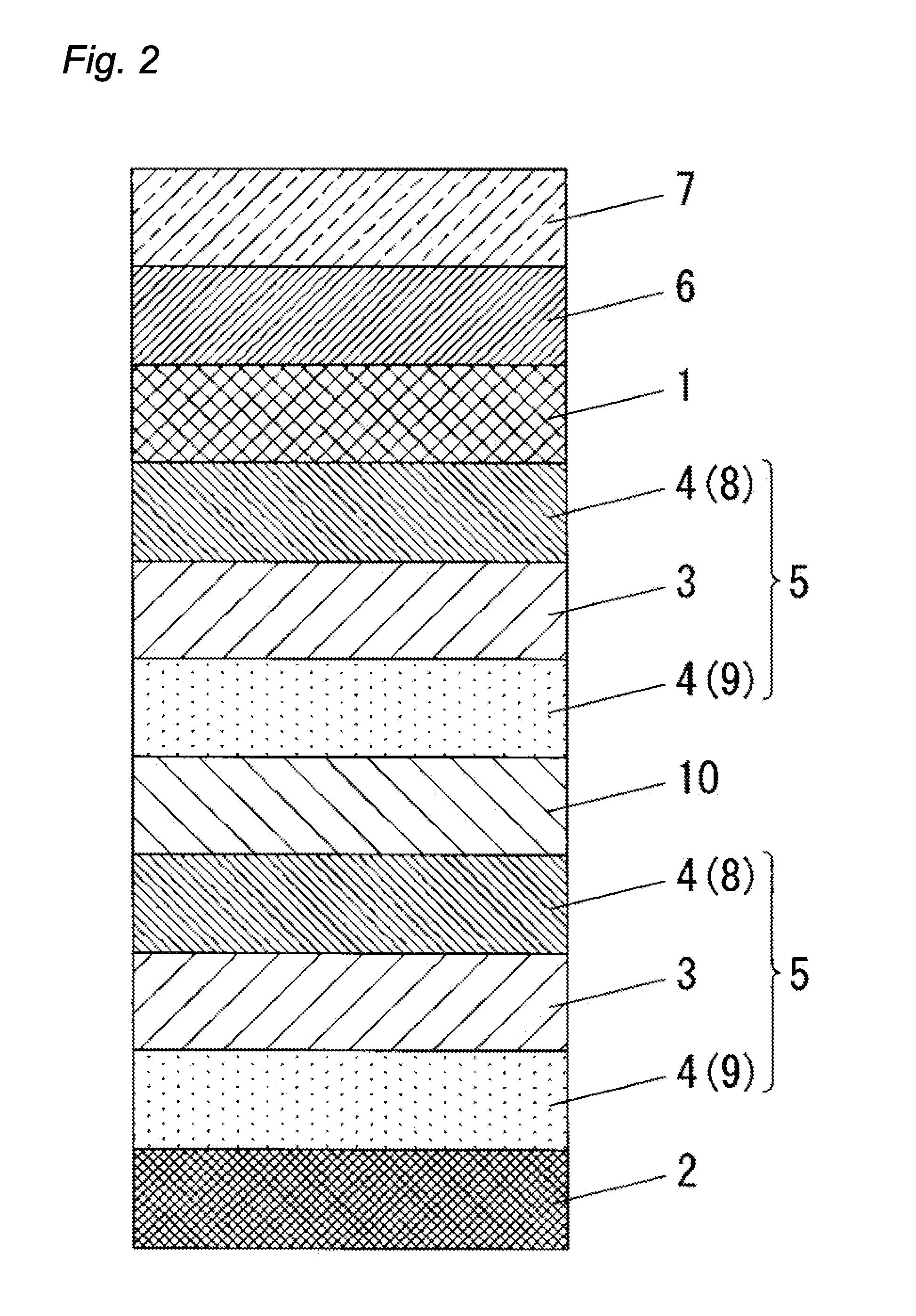

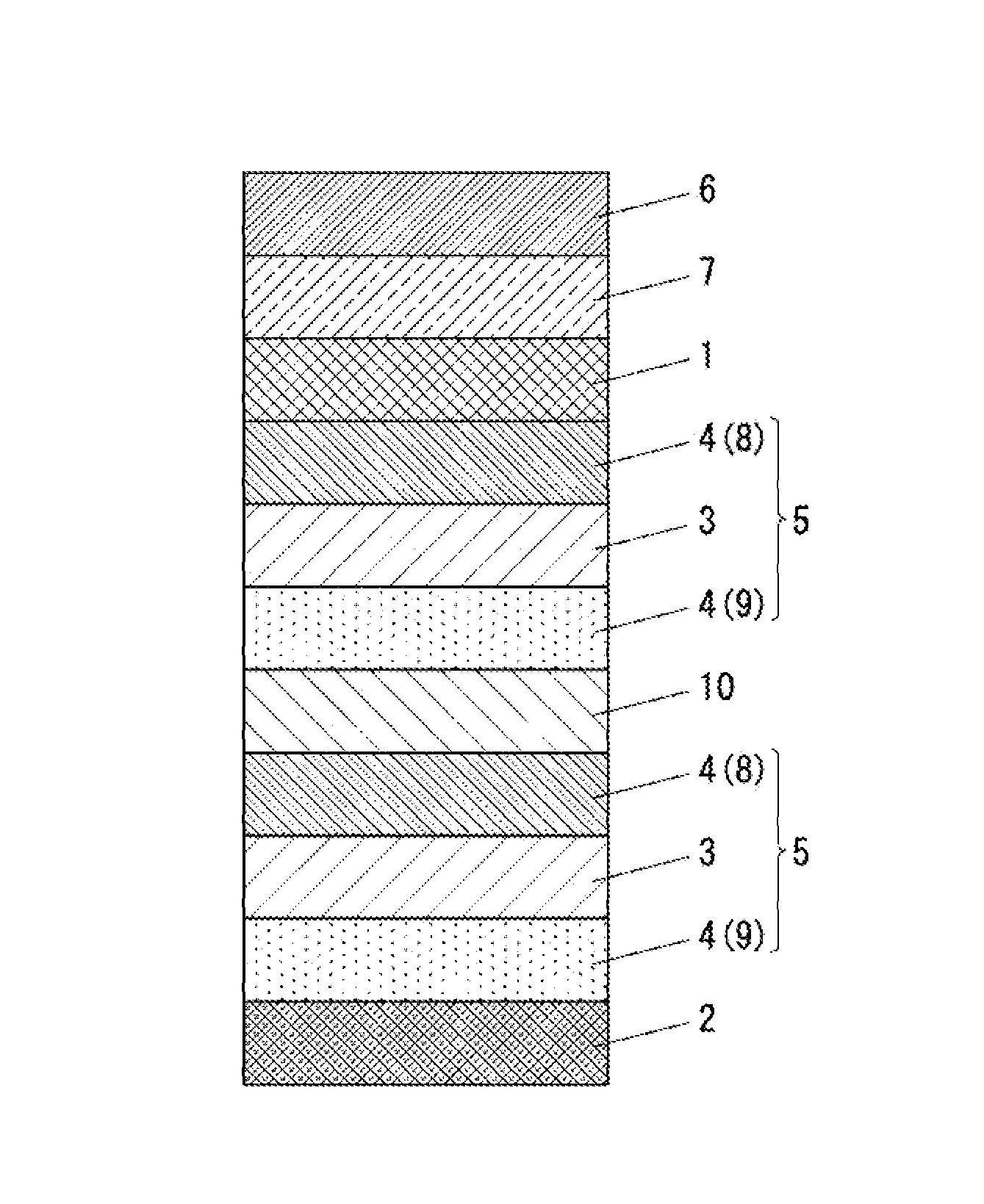

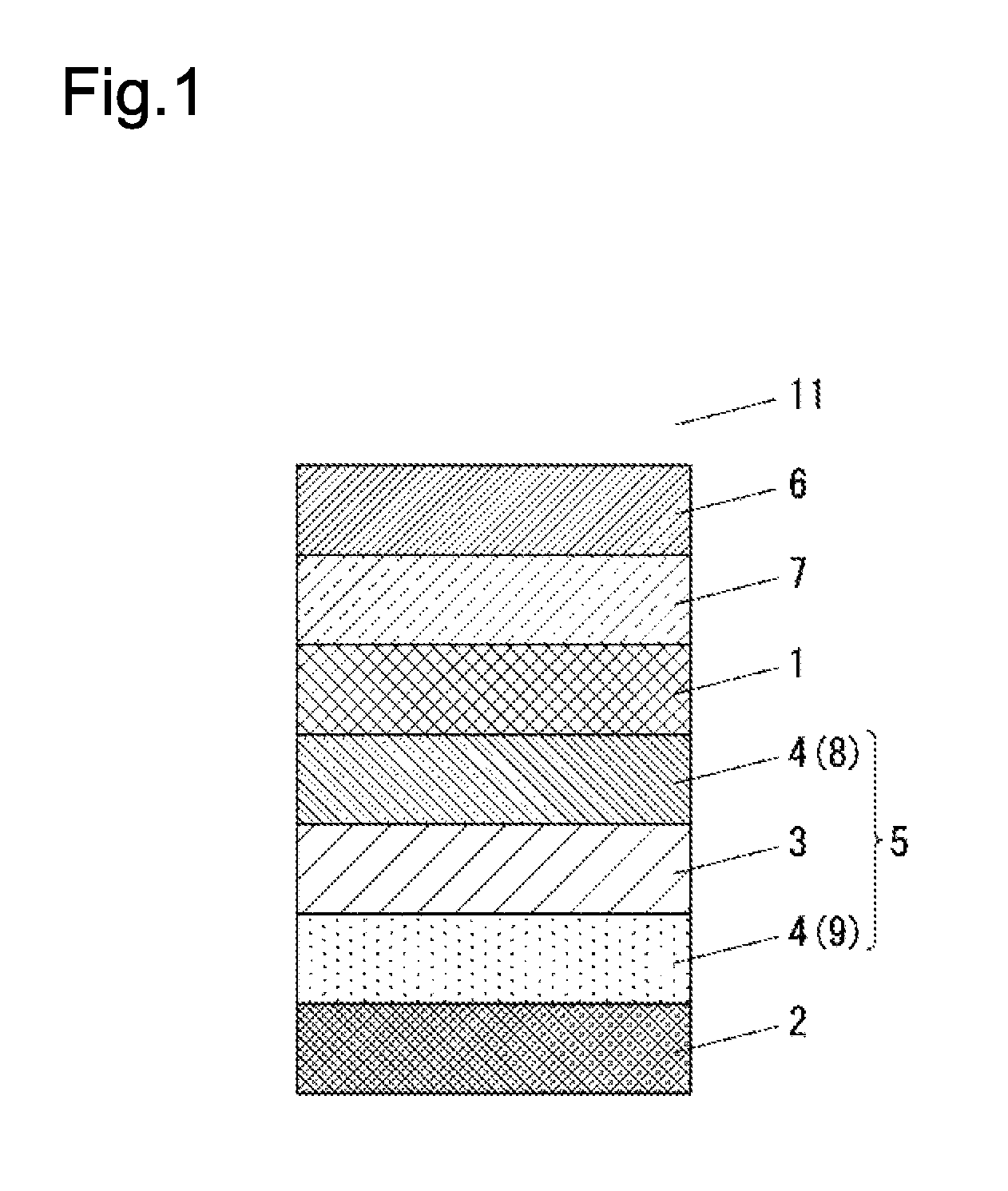

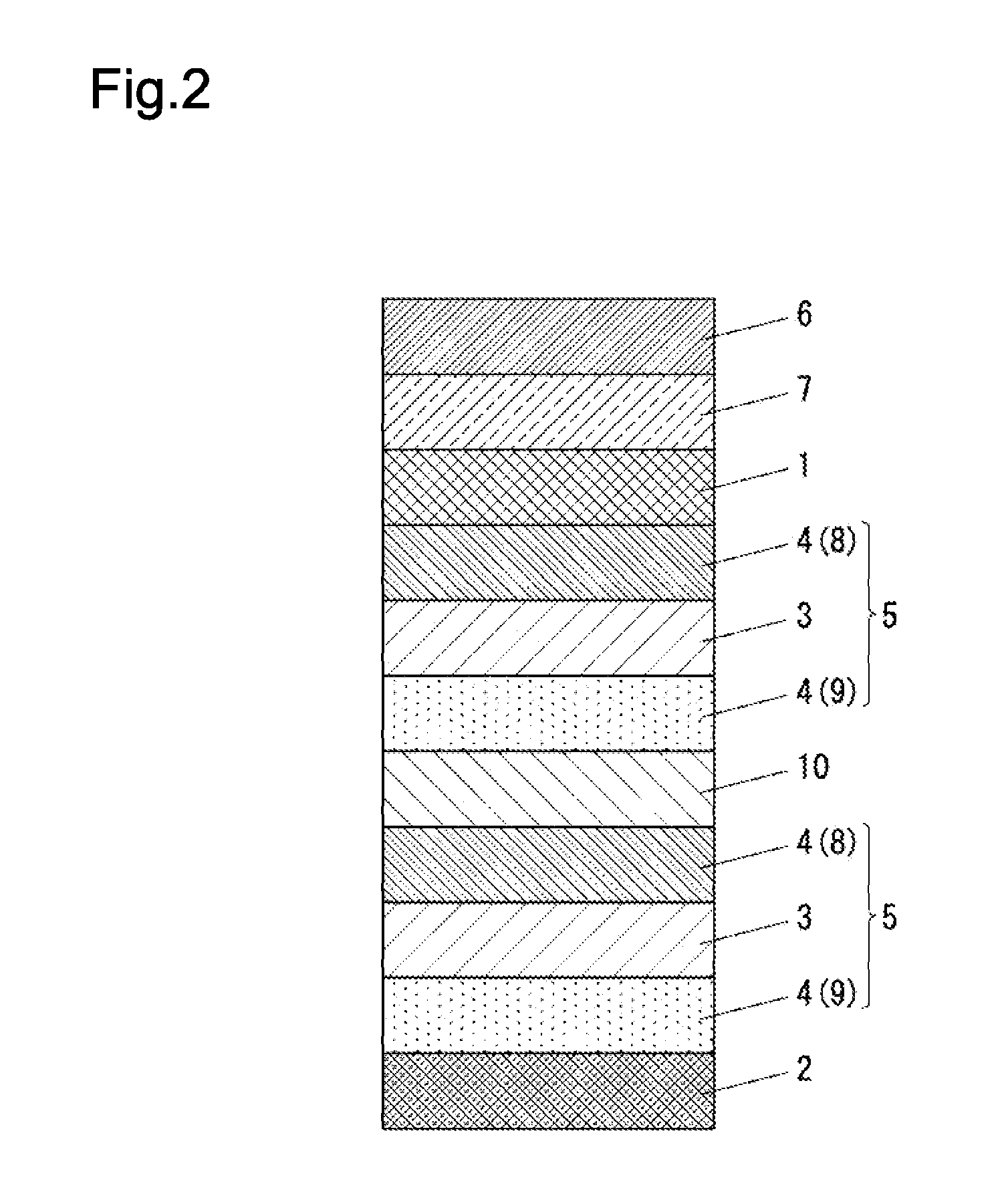

Organic electroluminescence element

InactiveCN102257649AIncrease beamIncrease the number of photonsElectroluminescent light sourcesSolid-state devicesRefractive indexOrganic electroluminescence

Provided is an organic electroluminescence element wherein the light-reflecting electrode is separated by the distance d, which is specified by the following formula (1), from the light-emitting point of the light-emitting layer, where lambda is the wavelength of specified light radiated from the light-emitting layer. n is the refractive index at wavelength lambda of the layer disposed between the light-emitting point of the light-emitting layer and the light-reflecting electrode. n1 and k1 are the refractive index and extinction coefficient of light having wavelength lambda in the layer that contacts the light-reflecting electrode. n2 and k2 are the refractive index and extinction coefficient at wavelength lambda of the light-reflecting electrode. m is 0 or 1. a satisfies the following formula when m is 0 or 1. -1.17norg / nEML+1.94a-0.16norg / nEML+2.33 0.28norg / nEML+0.75a2.85norg / nEML-1.23 norg is the refractive index at wavelength lambda of the layer that contacts the light-emitting layer on the light-reflecting electrode side. nEML is the refractive index at wavelength lambda of the light-emitting layer.

Owner:PANASONIC CORP

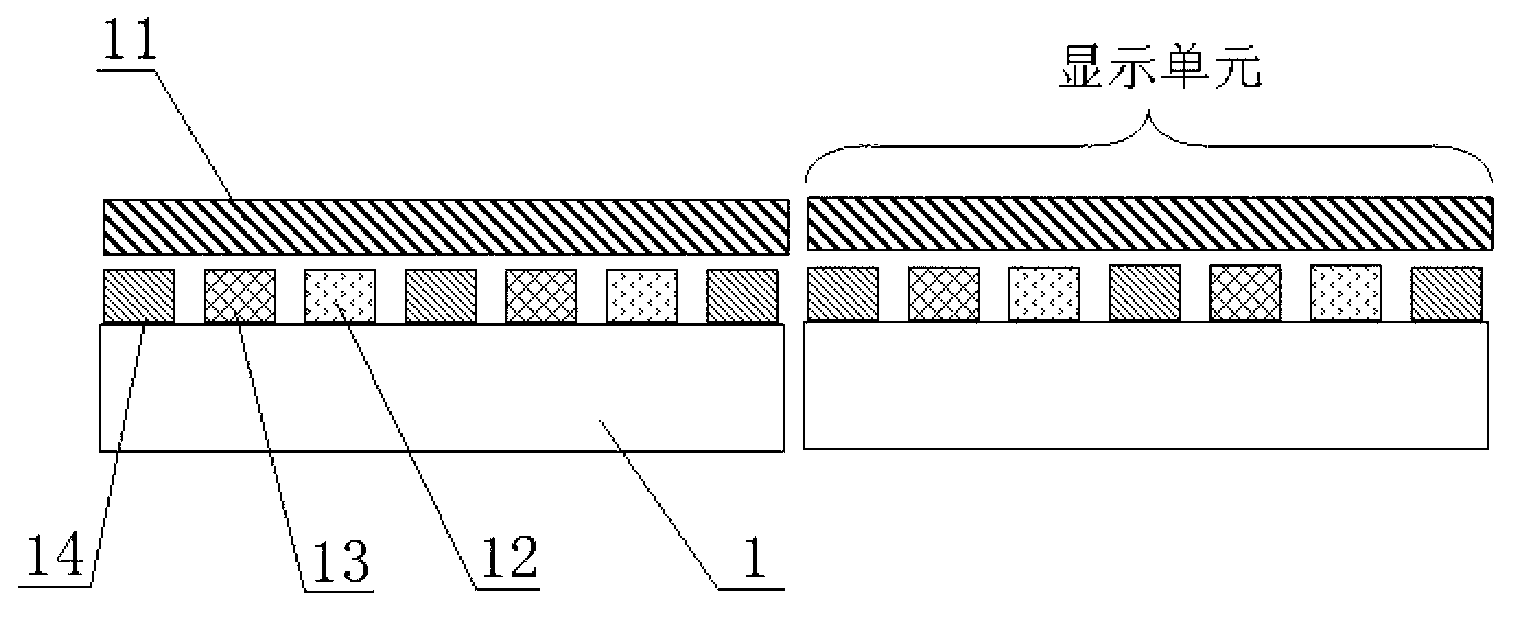

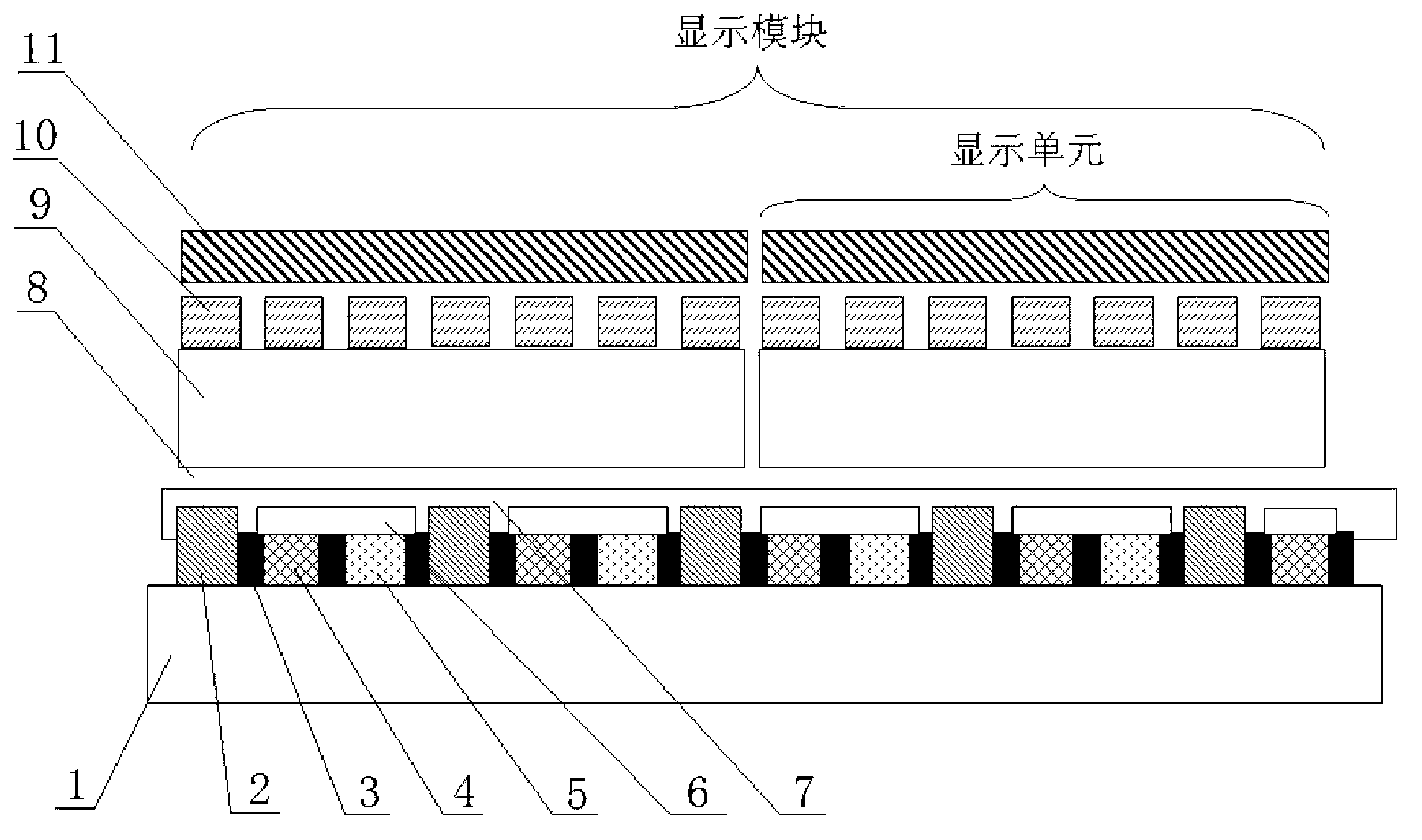

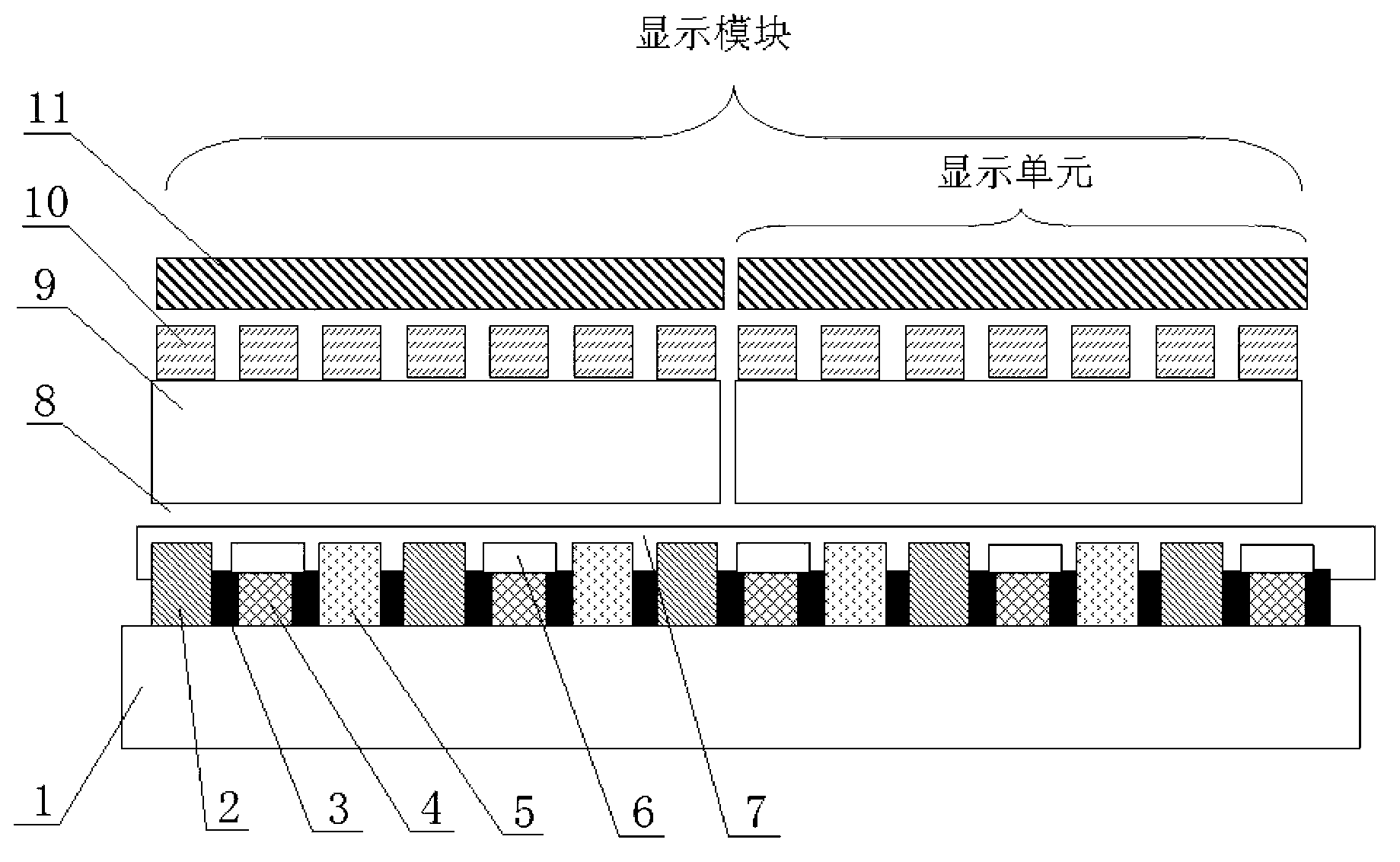

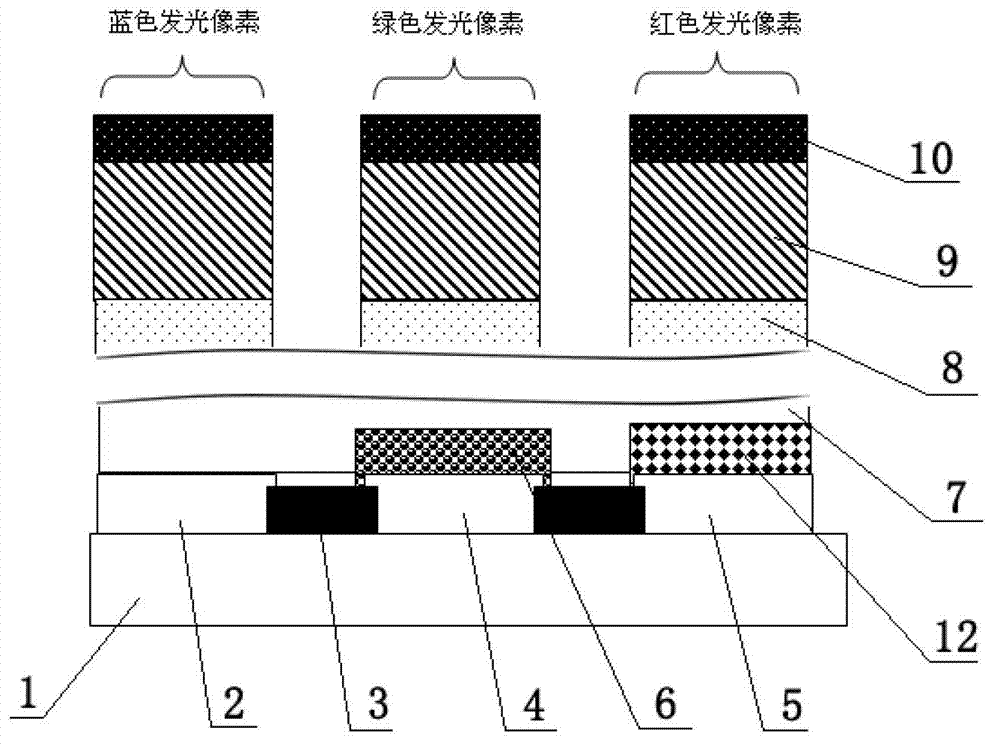

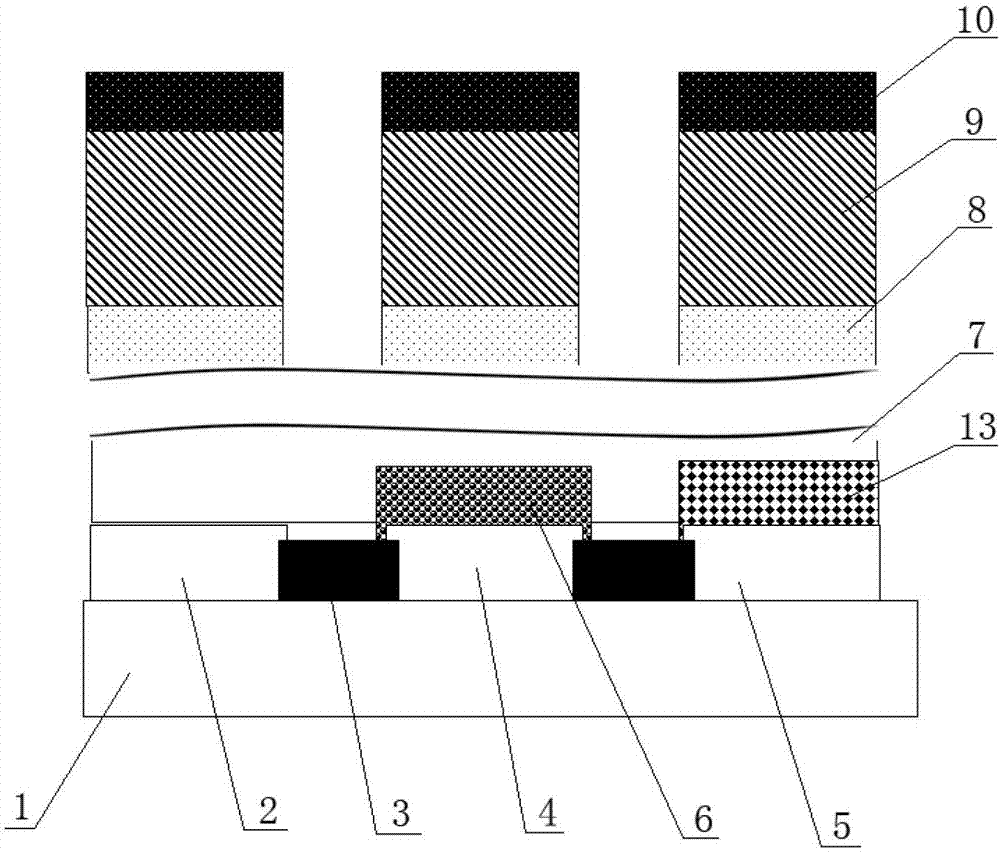

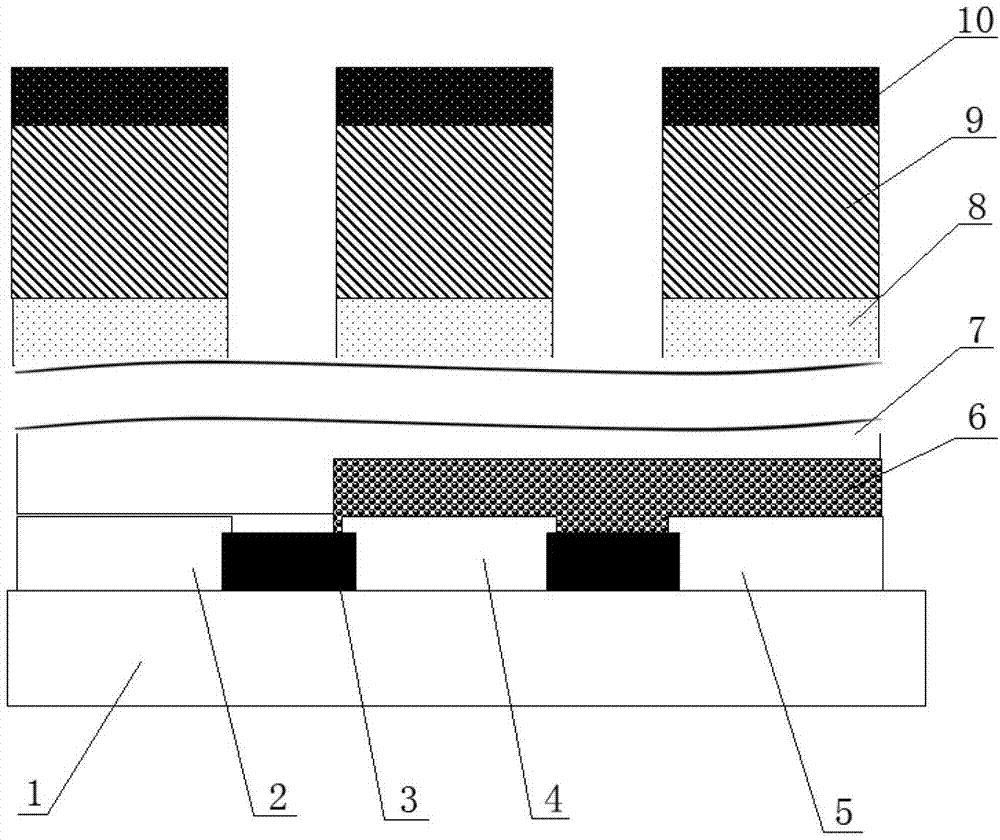

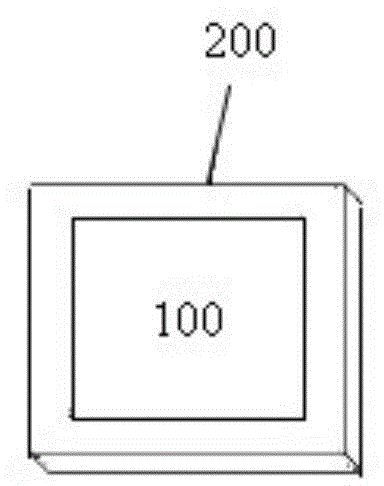

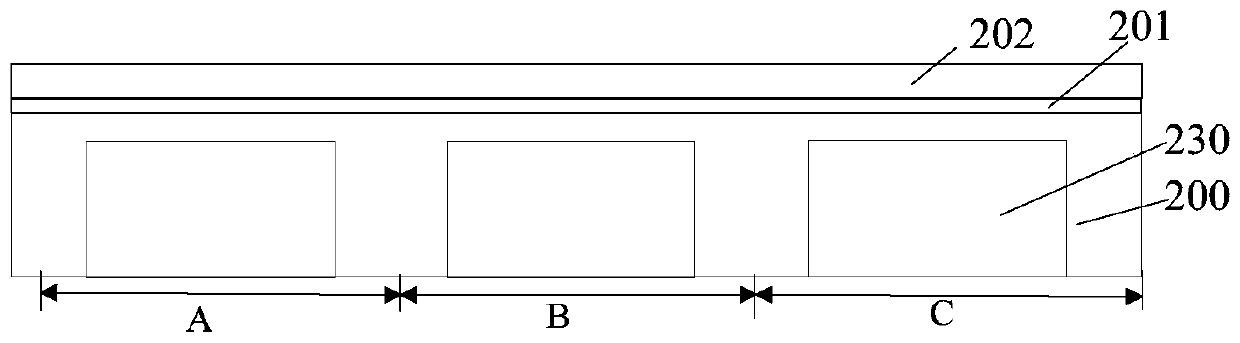

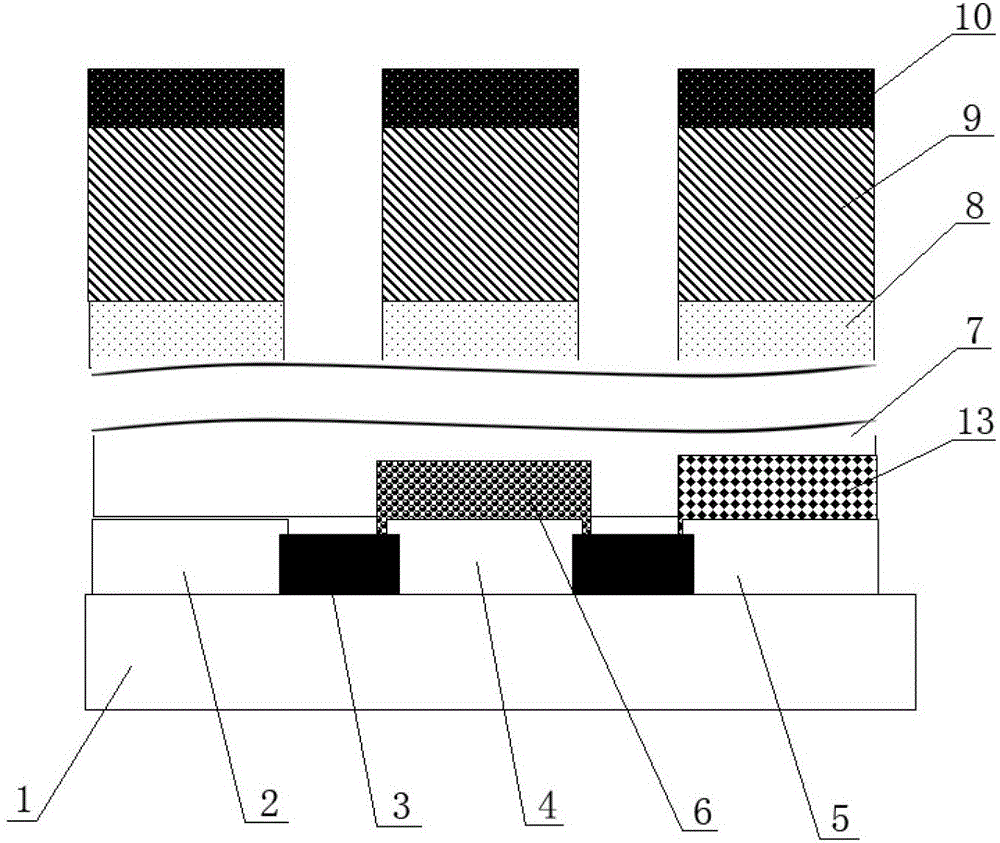

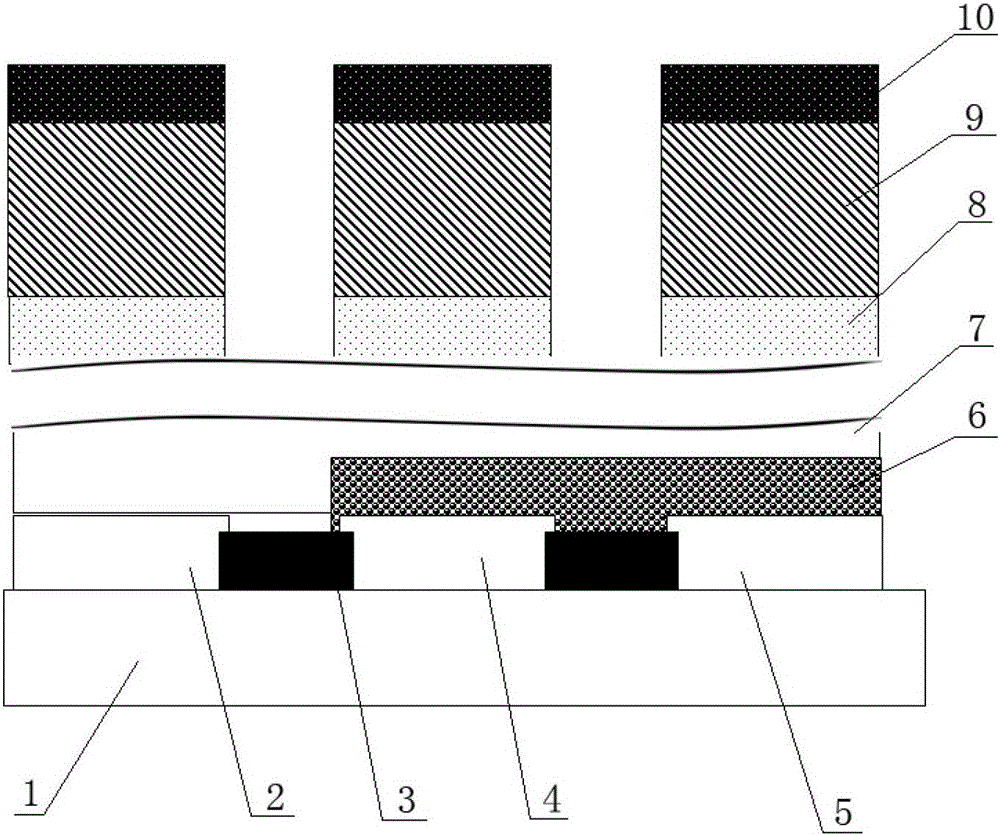

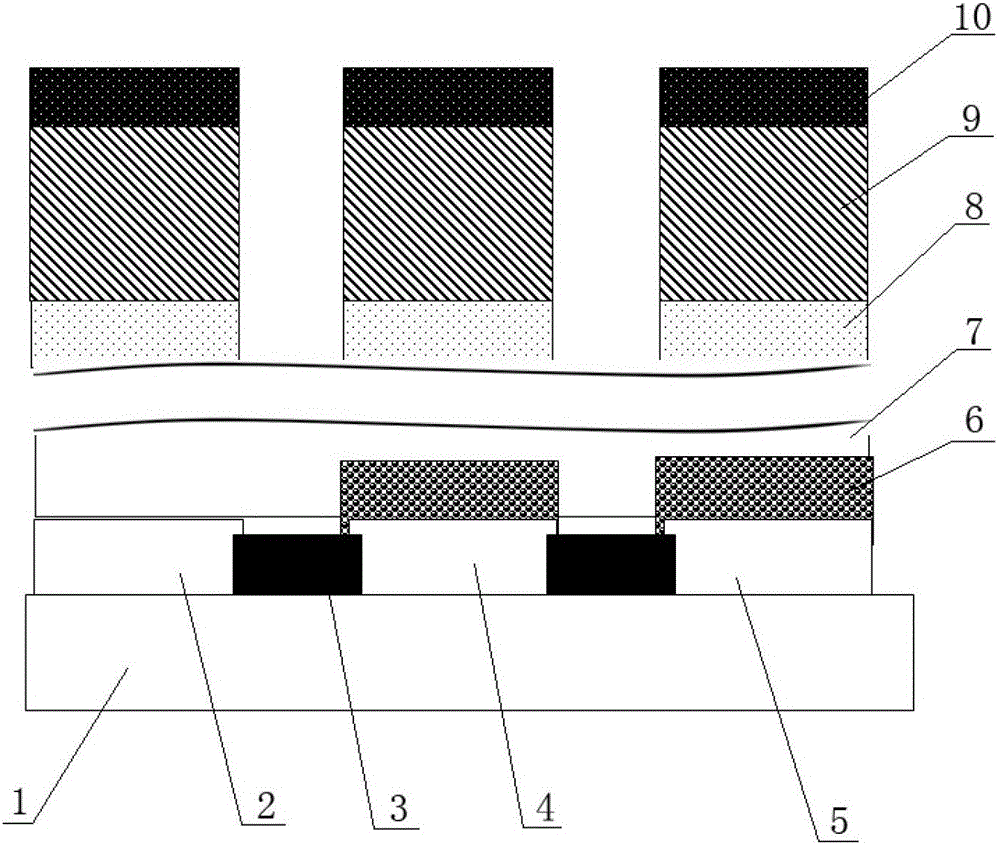

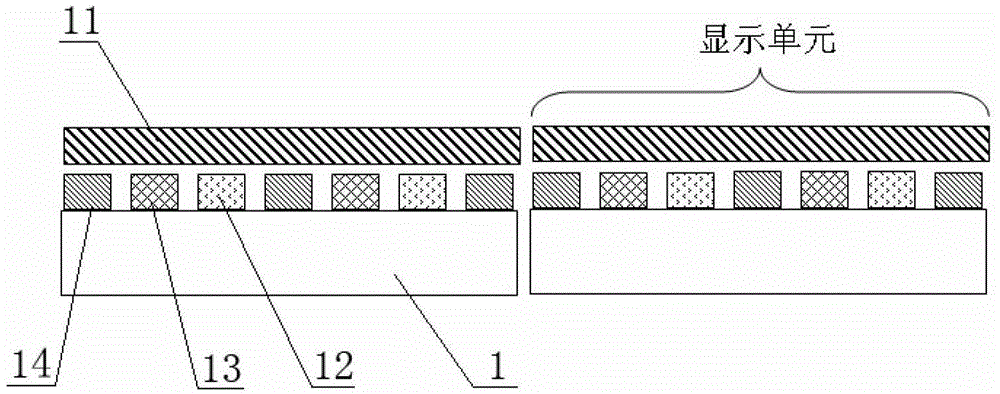

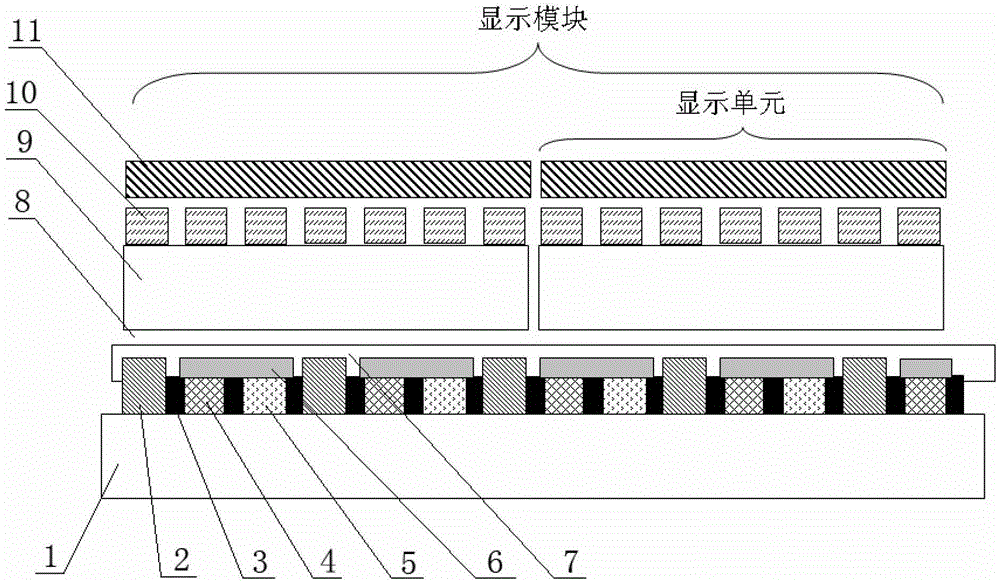

Large-size full-color OLED (Organic Light-Emitting Diode) display

ActiveCN102916035AImprove visual effectsImprove yield rateSolid-state devicesSemiconductor/solid-state device manufacturingDisplay devicePrice ratio

The invention relates to a large-size full-color OLED (Organic Light-Emitting Diode) display, which comprises a complete color converting base plate and a display module. The large-size full-color OLED display is characterized in that a green color converting film is covered on a green filter plate film; the display module is formed by assembling a plurality of display units; each display unit comprises a transparent base plate, a plurality of OLED luminescent devices and a control loop for driving the OLED luminescent devices to radiate light; the transparent base plates are seamlessly adhered onto a red filter plate film, a green filter plate film, a blue filter plate film, a black matrix grid film and a green color converting film on the color converting base plate through colloidal packing material; and each OLED luminescent device in the display unit has a filter plate film on the color converting base plate corresponding to the OLED luminescent device independently. The large-size full-color OLED display has the advantages of being good in visual effect, high in yield and the like, is capable of being convenient to realize size dimension, and is beneficial for improving the performance price ratio for manufacturing the display.

Owner:JIANGSU SUNERA TECH CO LTD

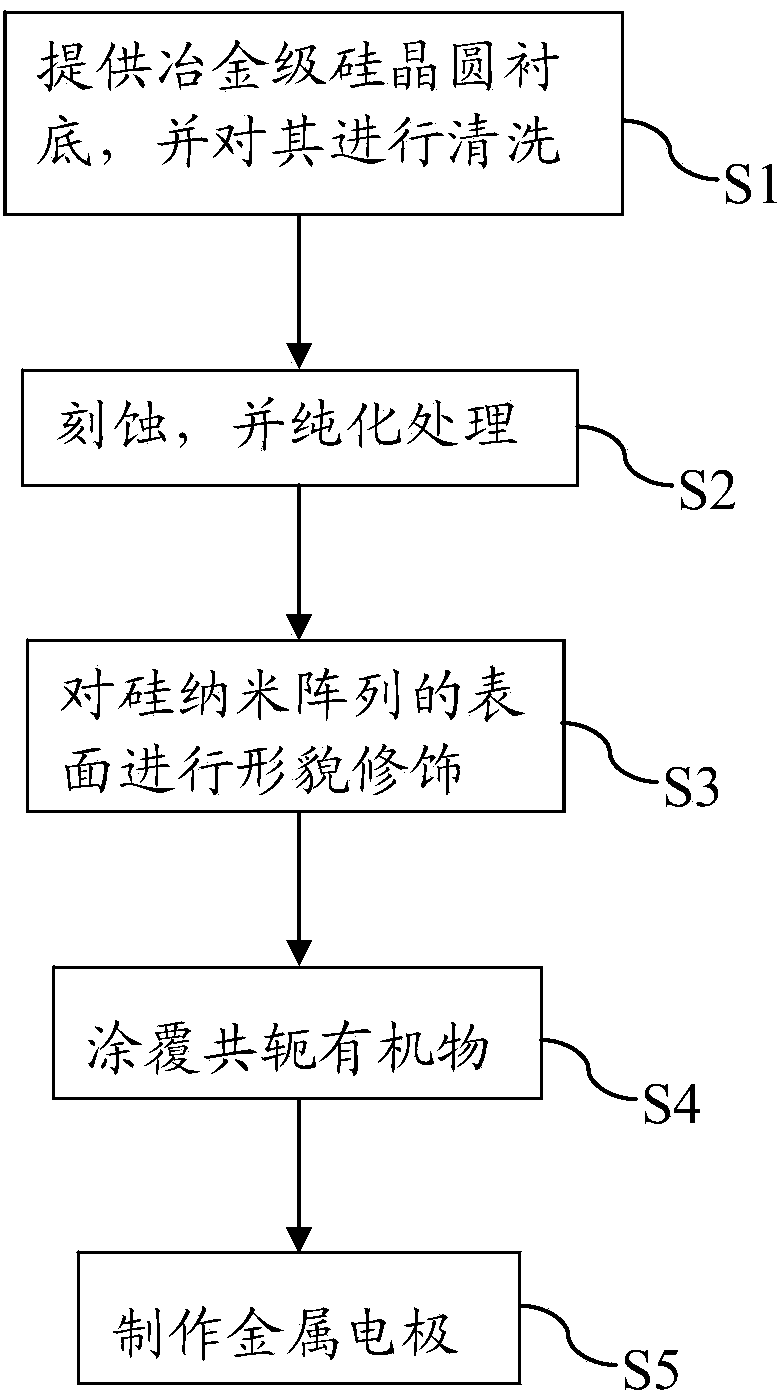

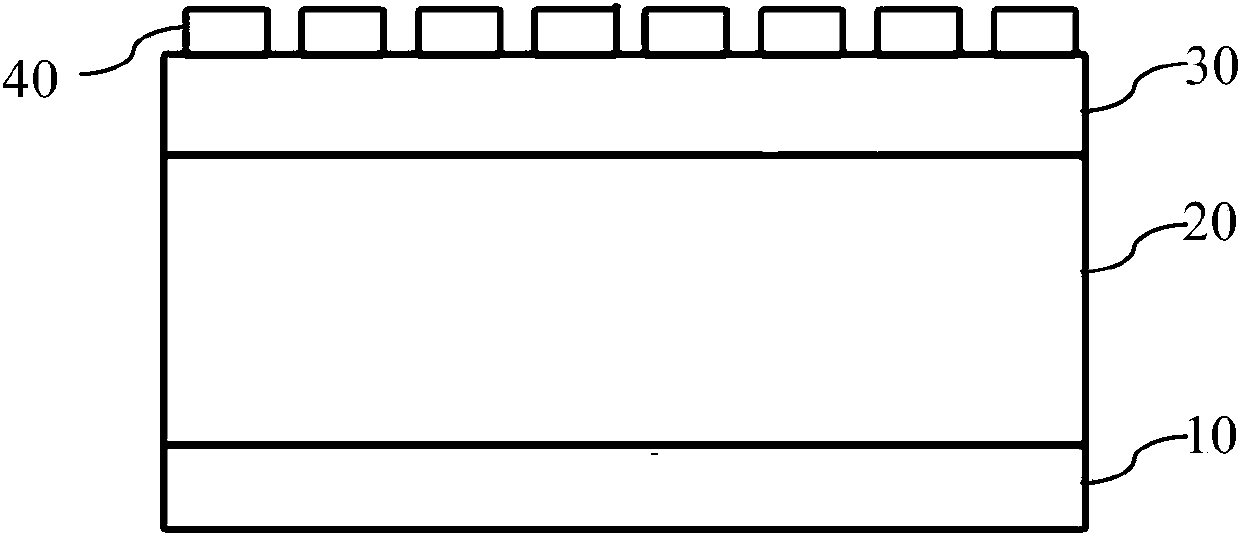

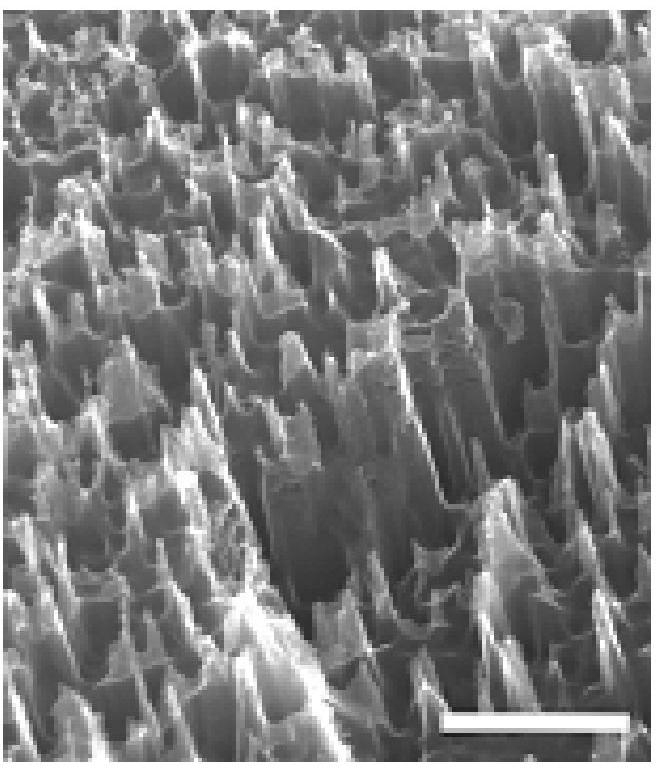

Silicon solar cell and manufacturing method thereof

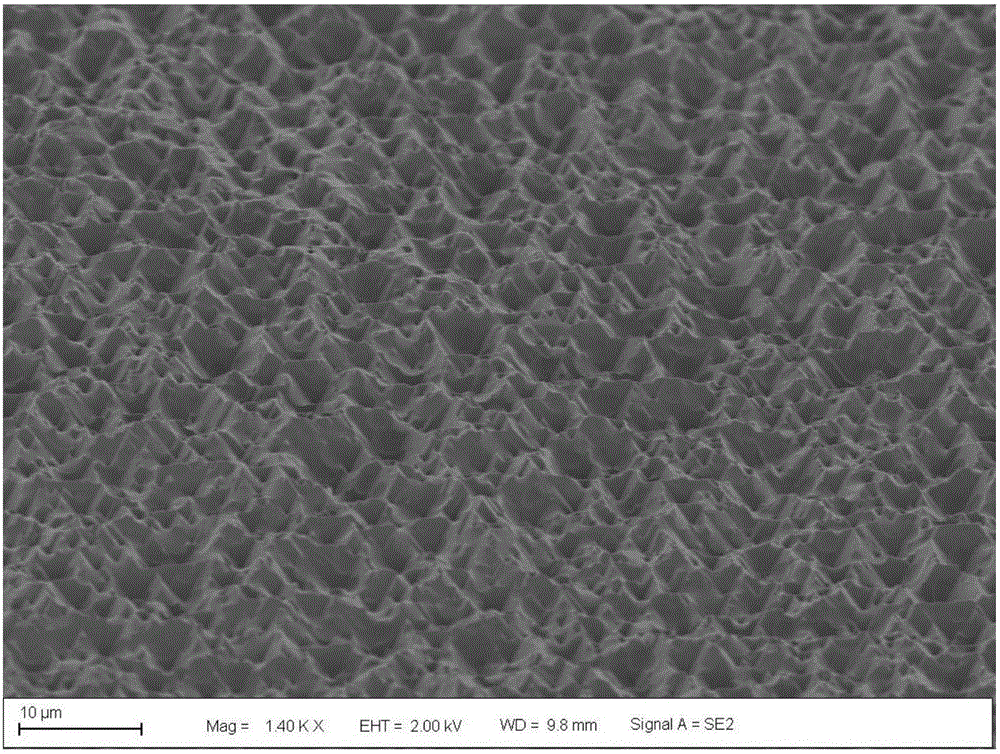

ActiveCN104051580AEnhanced charge transport capabilityImprove stabilityFinal product manufacturePhotovoltaic energy generationHeterojunctionSilicon solar cell

The invention discloses a silicon solar cell and a manufacturing method of the silicon solar cell. The manufacturing method of the silicon solar cell includes the following steps of firstly providing a metallurgical grade silicon wafer substrate and cleaning the metallurgical grade silicon wafer substrate, secondly etching the metallurgical grade silicon wafer substrate and conducting purification on the metallurgical grade silicon wafer substrate, thirdly conducting morphology modification on the surface of a silicon nanometer array, fourthly conducting morphology modification on the surface of the silicon nanometer array again, and fifthly coating the silicon nanometer array with conjugated organic matter. According to the manufacturing method of the silicon solar cell, the metallurgical grade silicon materials are applied to preparation of the solar cell, surface morphology treatment and surface purification treatment are conducted on the metallurgical grade silicon materials by fully applying the wet metal auxiliary chemical etching technology, and a silicon nanometer structure is formed. Passivating treatment is conducted on organic materials and the silicon nanometer structure, electrical performance and optical performance of a metallurgical grade silicon cell are improved, and charge separation performance and charge transmission performance are improved. Stability of the cell is improved through modification to organic-inorganic hybrid heterojunction, and the charge transmission capacity of the solar cell is enhanced.

Owner:SUZHOU INAINK ELECTRONICS MATERIALS CO LTD

LED head and photon extractor

InactiveUS20130182444A1Increase capacityImprove efficiencySolid-state devicesOptical light guidesRefractive indexSemiconductor chip

The invention concerns a semiconductor based light source comprising a back part, a front side and at least one semiconductor chip having an emitting surface, at least one reflective optical element being arranged below said at least one semiconductor chip, a material with low refractive index being disposed on a side of said reflective optical element facing said front side, wherein said semiconductor based light source comprises on said front side a compound material with high refractive index having at least one diffractive optical element embedded therein, such as to direct light incident on said diffractive optical element towards preferred directions.

Owner:BLACKBRITE

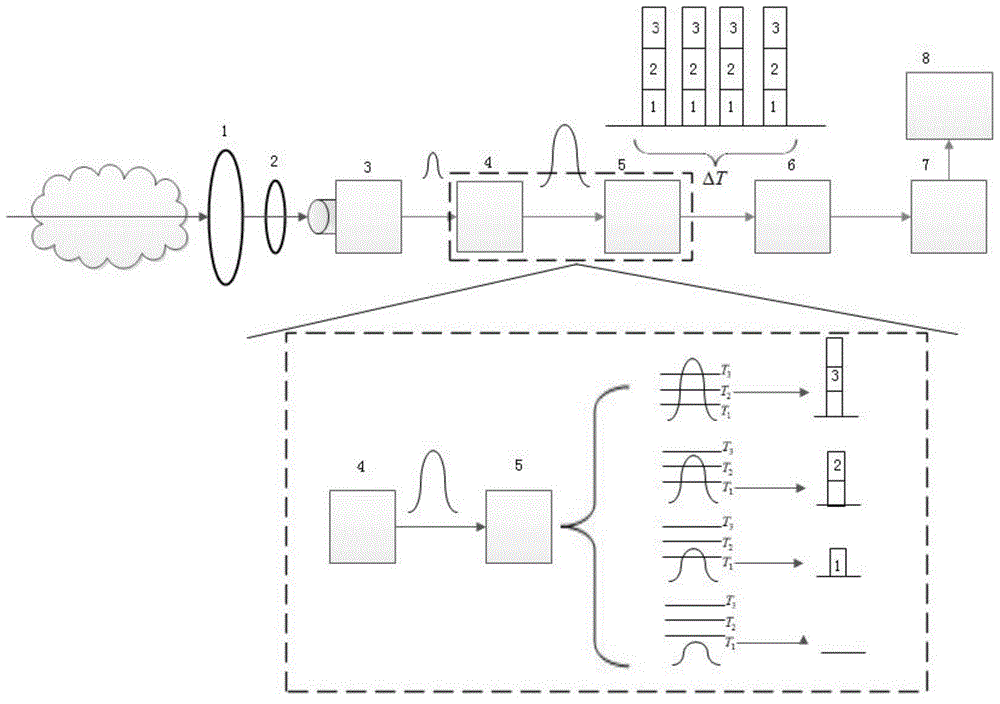

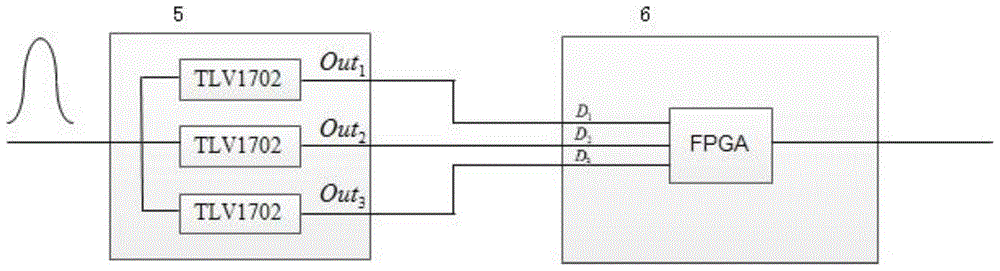

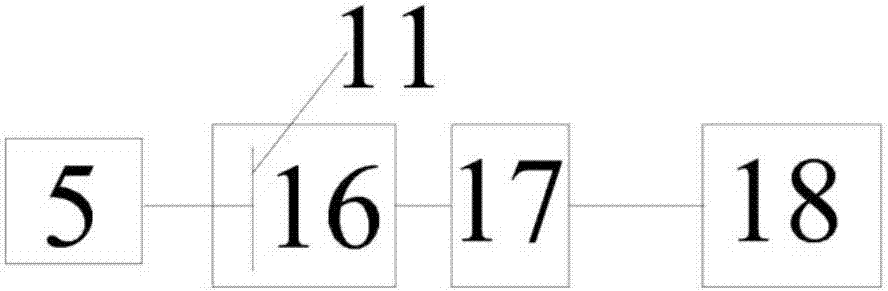

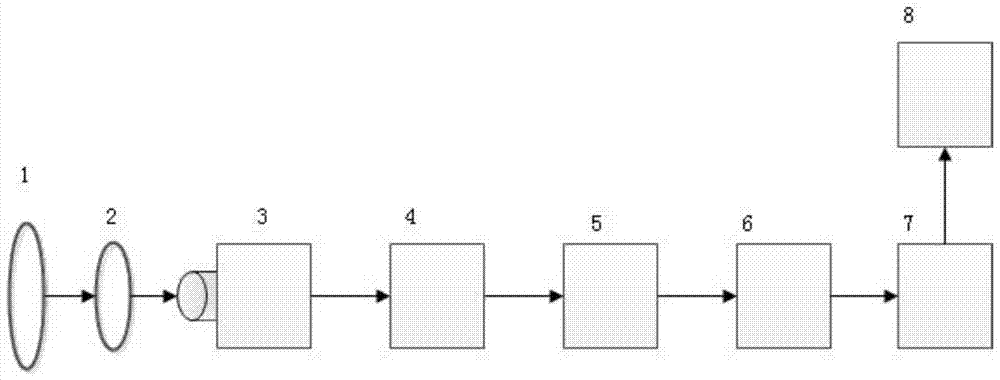

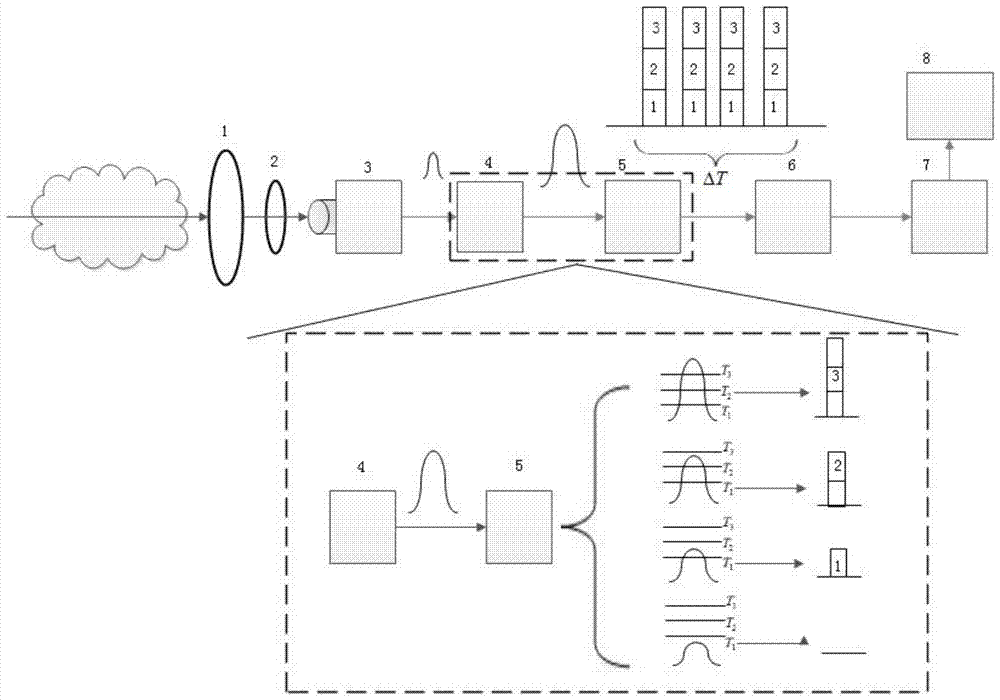

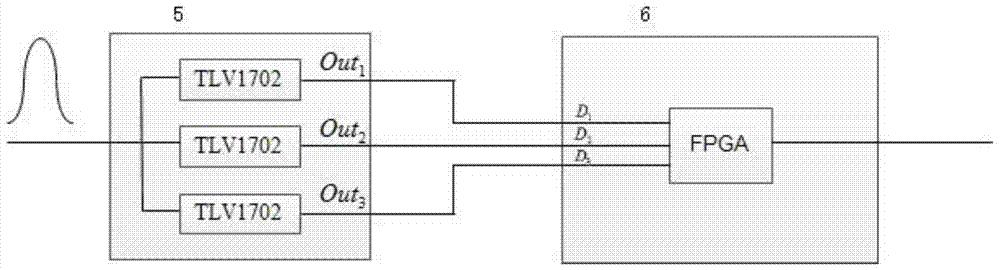

Photon counting type communication receiving device capable of distinguishing photon numbers

ActiveCN104579498AReduce bit error rateIncrease the number of photonsElectromagnetic receiversPhotomultiplierPhoton counter

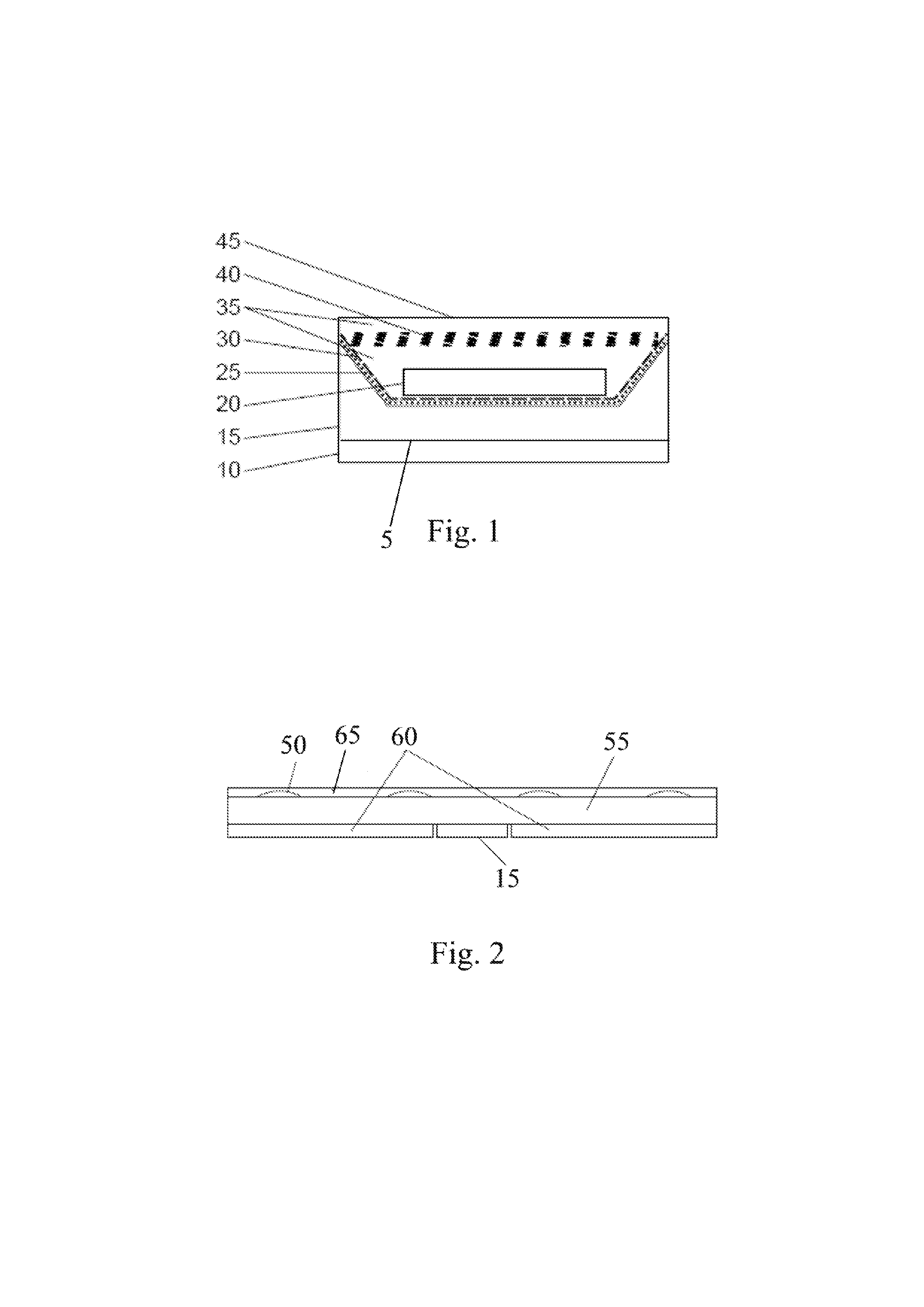

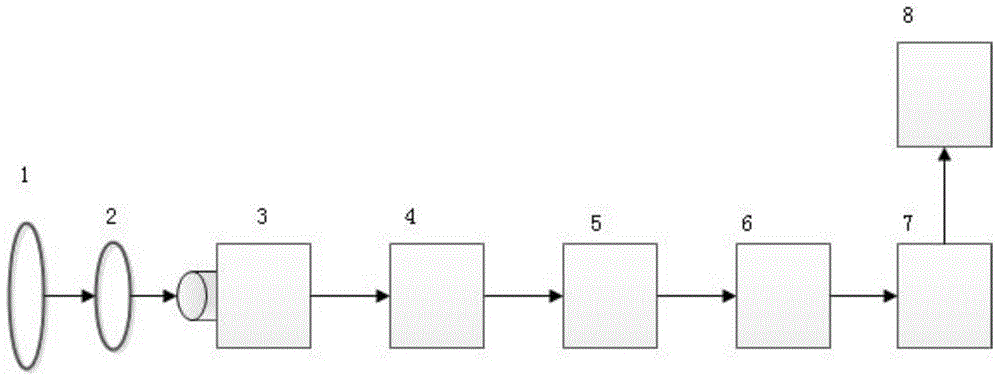

A photon counting type communication receiving device capable of distinguishing photon numbers is composed of a receiving lens, an interference filter, a photomultiplier, an amplifier, a comparator, a photon counter, a demodulation decoder and an upper computer in sequence. The photon counting type communication receiving device is characterized in that the comparator is a multilevel comparator composed by connecting two or more micro-power consumption comparison chips in parallel, each micro-power consumption comparison chip is set with a comparison threshold, and the photon counter is a multi-photon counter. The photon counting type communication receiving device has the advantage, also achieved by a traditional single-photon counting type communication device, of high weak light response sensitivity; the bit error rate can be reduced remarkably, and communication reliability is guaranteed.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

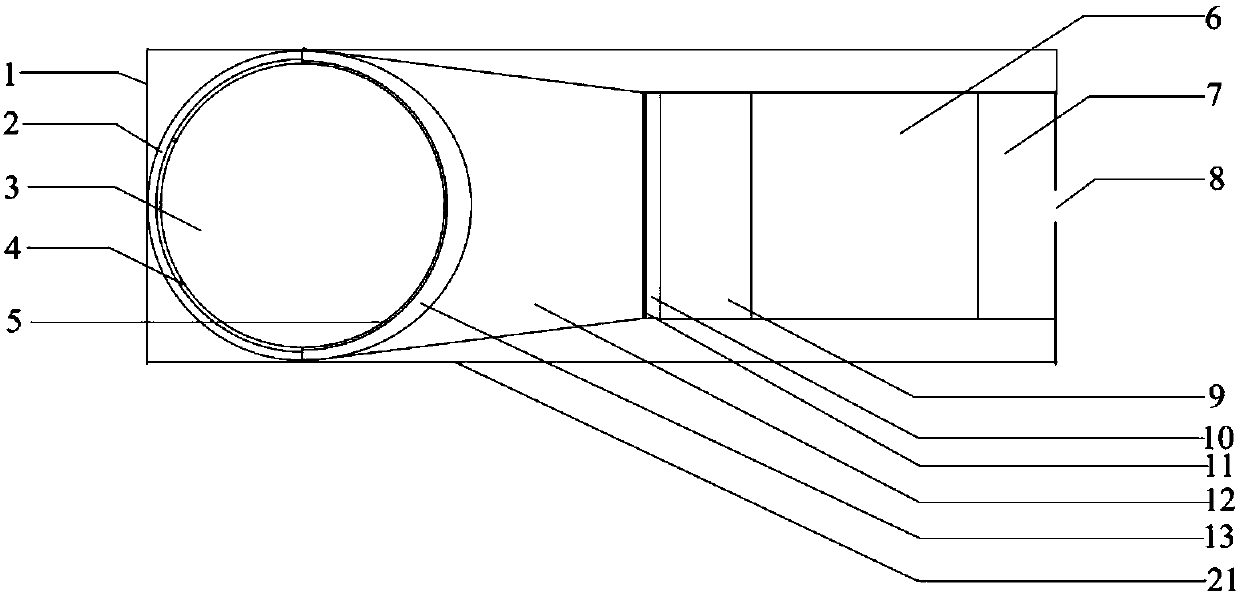

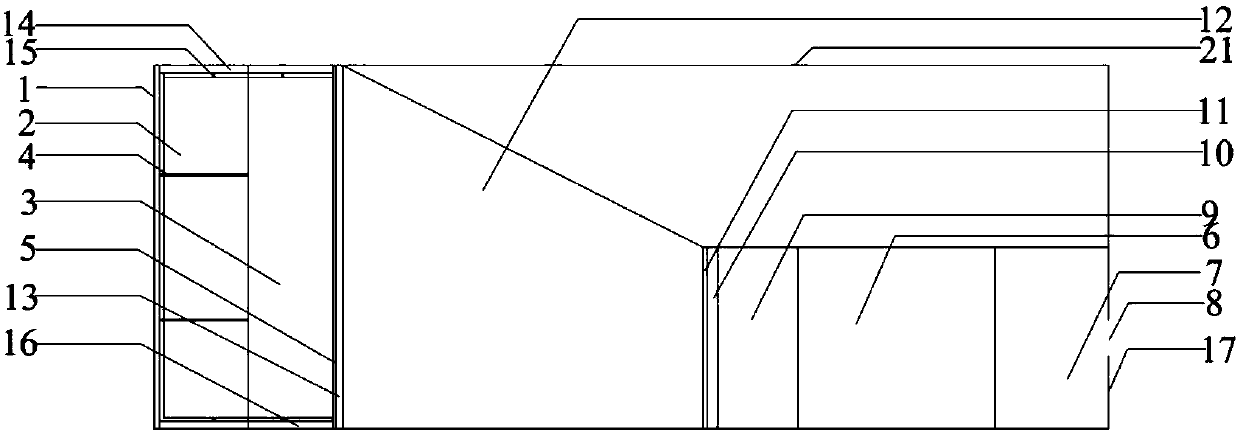

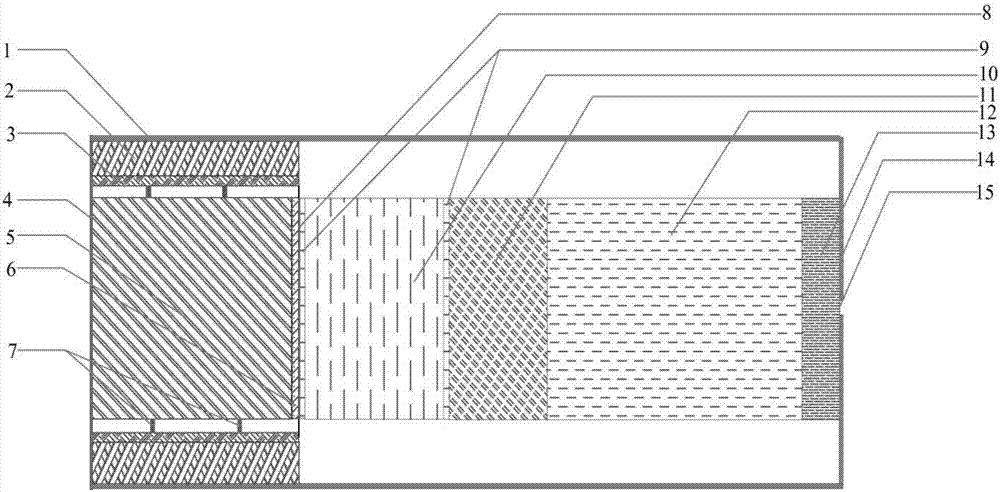

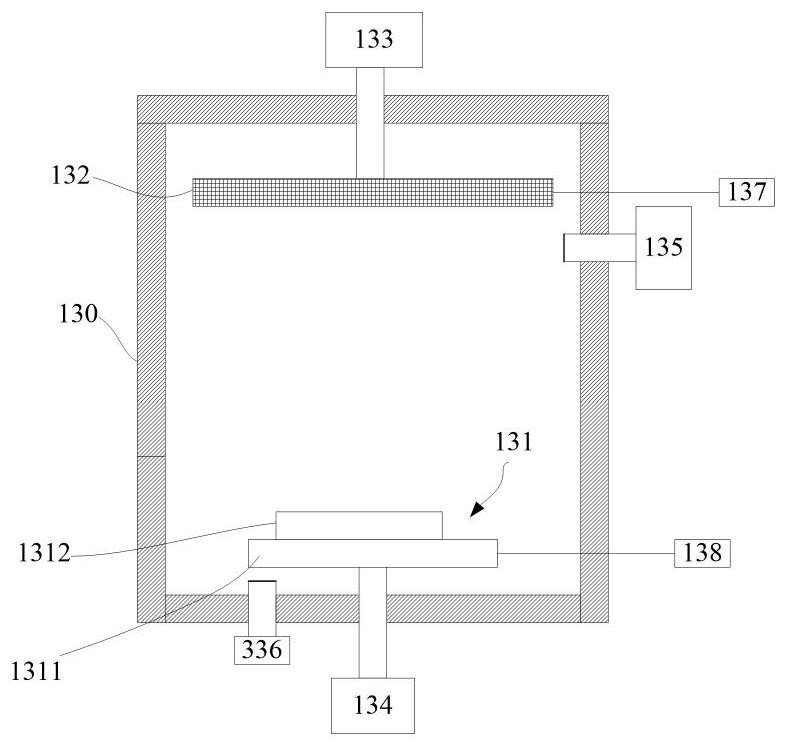

Novel scintillation detector with high photon transmission efficiency

InactiveCN107688193AImprove collection effectIncrease effective countX/gamma/cosmic radiation measurmentOptical pathlengthIonizing radiation

The invention discloses a novel scintillation detector with high photon transmission efficiency. The novel scintillation detector has the principle that when rays enters a crystal, secondary electronsare generated near the surface of the incidence end of the crystal (3), and fluorescence is generated; a part of fluorescence photons can be absorbed and consumed by the crystal and can escape to a position outside the crystal. The light path is reduced in a lateral window opening emitting mode; the photon collection is more facilitated. The escaped photon returns into the crystal (3) through thereflection by a reflecting layer; the generated photons pass through an antireflection film (5), a coupling agent (11), an optical glass convex lens (13) and a light guide cavity (12) to enter an optical cathode (9) of an electronics system (22) for generating photoelectrons; the photoelectrons are amplified and shaped by the subsequent electronic element to from a pulse signal; the event is finally recorded as a radiation event.

Owner:JILIN UNIV

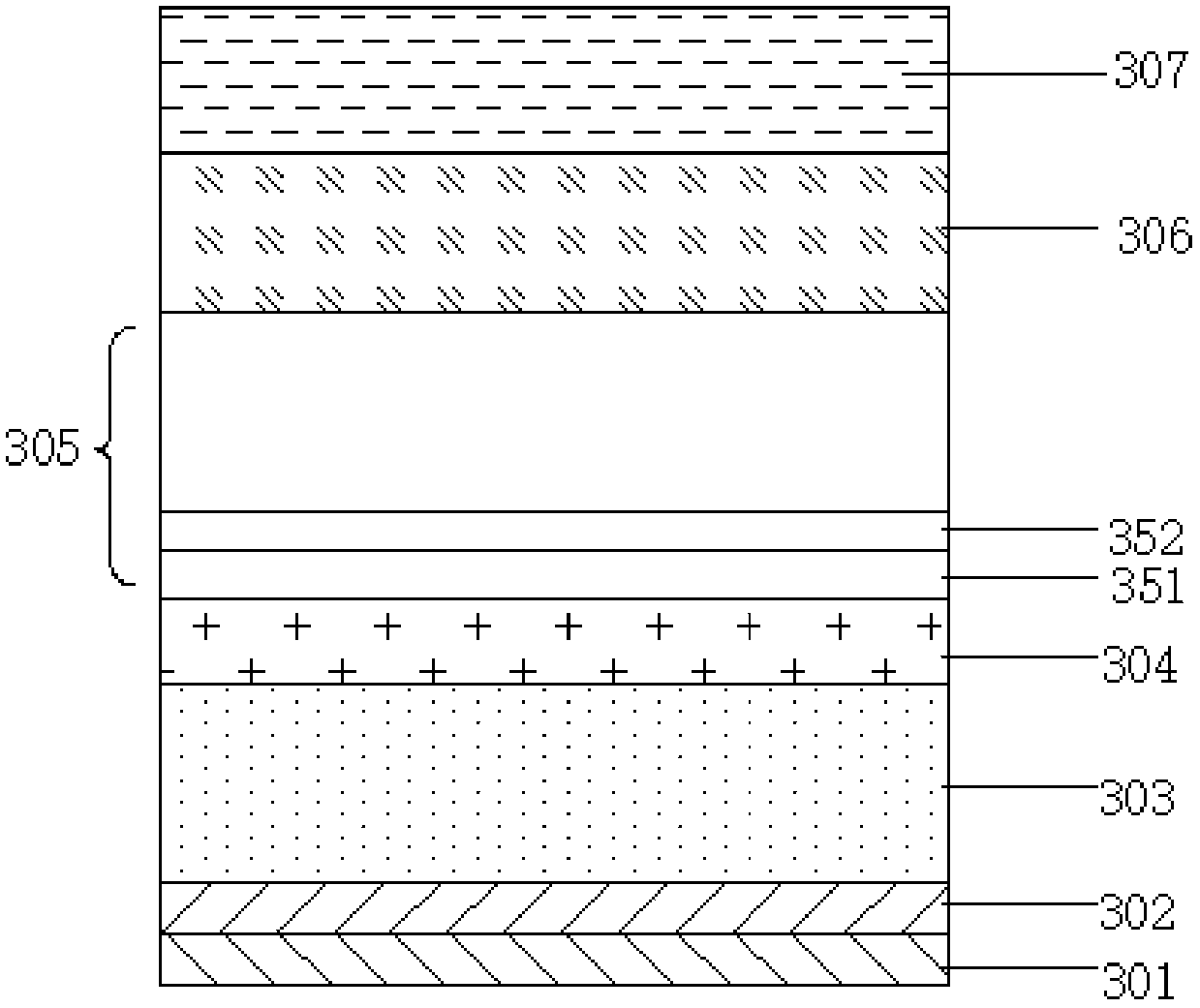

Full-color OLED (Organic Light Emitting Diode) display made by adopting multi-component OLED luminescent device technology and filtering technology

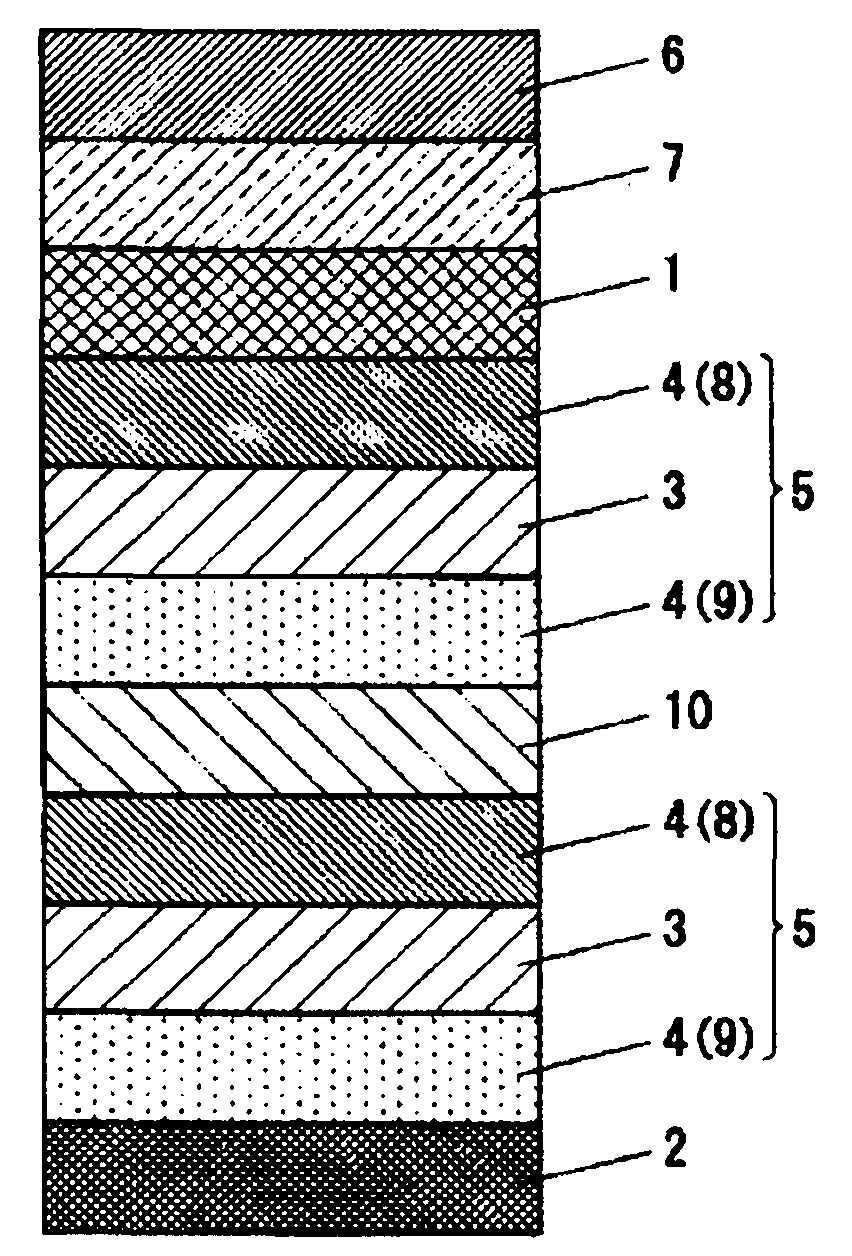

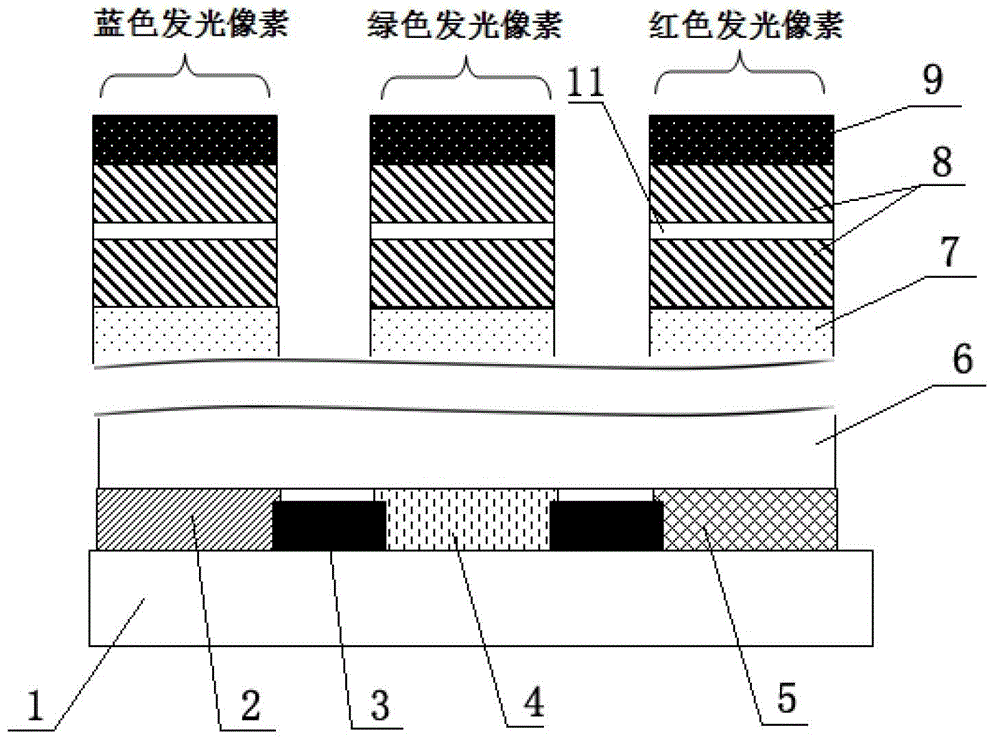

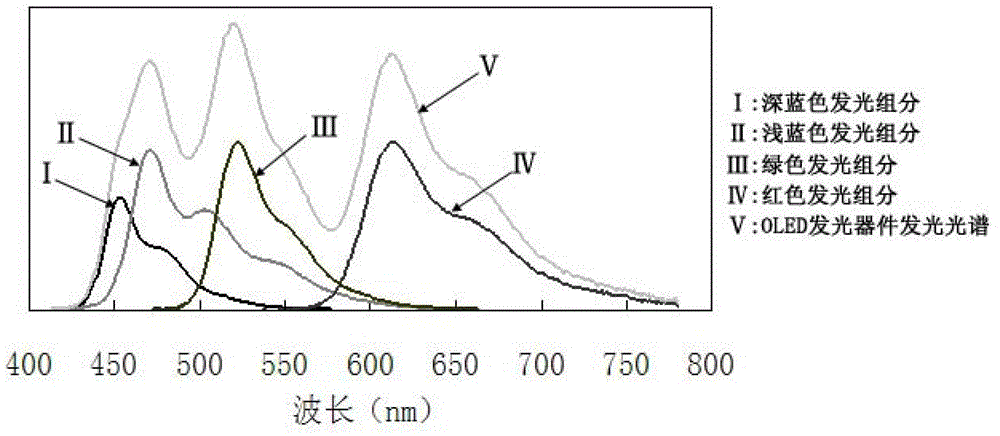

InactiveCN102982742ADoes not affect manufacturing process technologyIncrease contrastSolid-state devicesSemiconductor/solid-state device manufacturingFlexible organic light-emitting diodeDisplay device

The invention relates to a full-color OLED (Organic Light Emitting Diode) display made by adopting a multi-component OLED luminescent device technology and filtering technology. The full-color OLED display comprises an optical filter substrate, an OLED luminescent device and a drive unit used for driving the OLED luminescent device to emit light, wherein each optical filter membrane layer in the optical filter substrate is provided with an OLED luminescent device corresponding to the optical filter membrane layer, and all OLED luminescent devices are the same in structures. The full-color OLED display is characterized in that electroluminescent luminescent spectrums generated by the OLED luminescent devices under the electrifying condition comprise at least two groups of groups of blue light luminescent components with CIE (Commission International Eclairage) color coordinate Y values of less than 0.55, red light luminescent components with CIE color coordinate X values of more than 0.64, and green light luminescent components with CIE color coordinate Y values of more than 0.55. The full-color OLED display has the advantages of long service life, high fineness, high yield, large size and the like, and is beneficial to the increase of the total manufacture cost performance of the display.

Owner:李崇

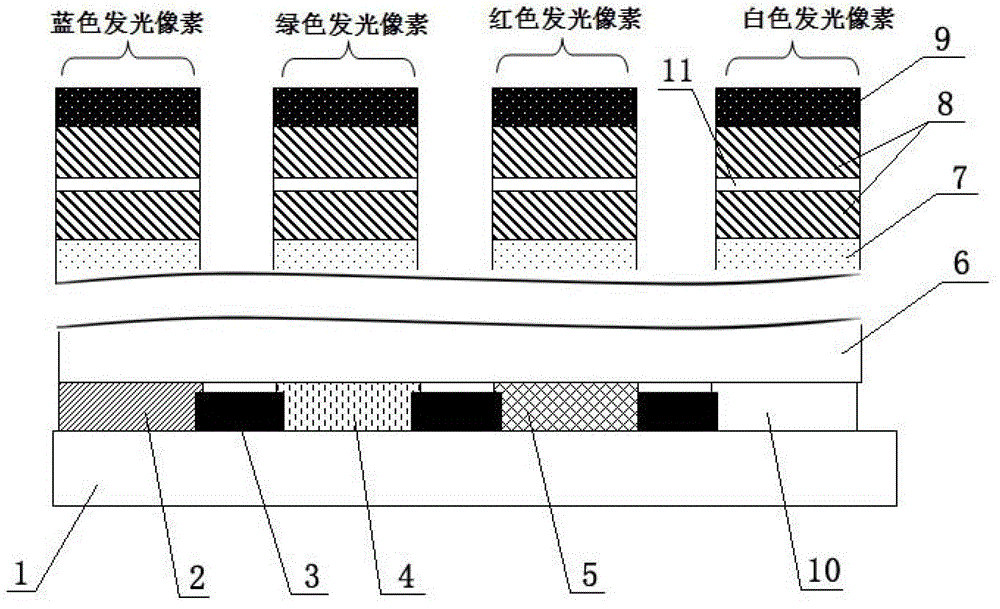

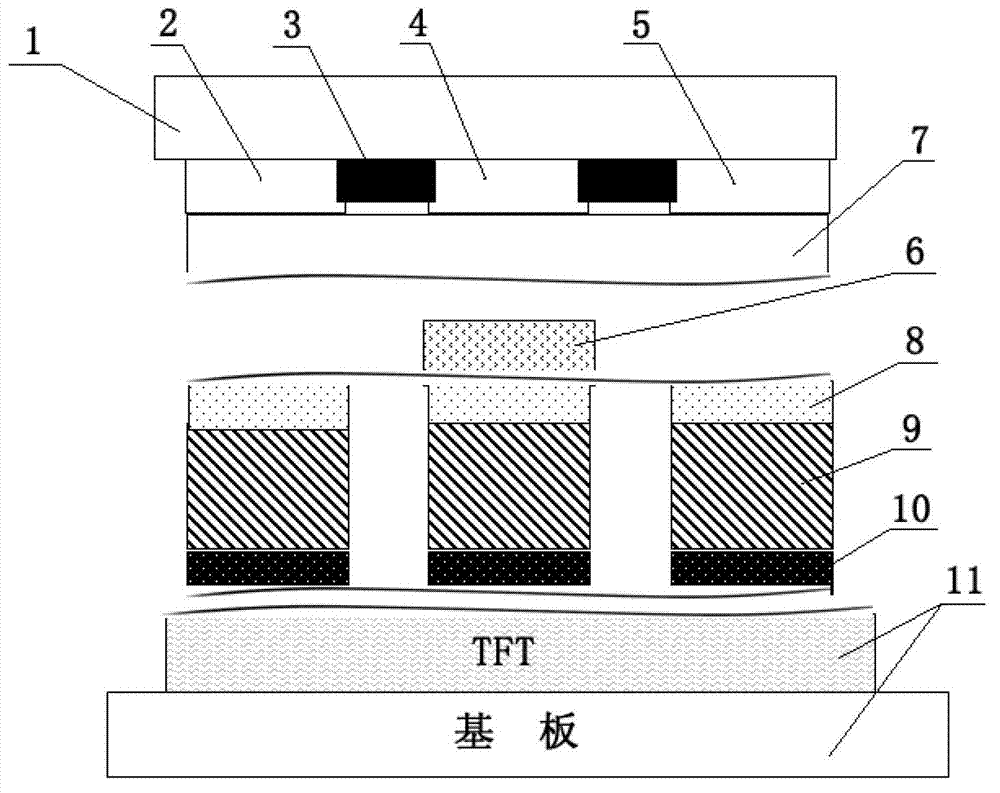

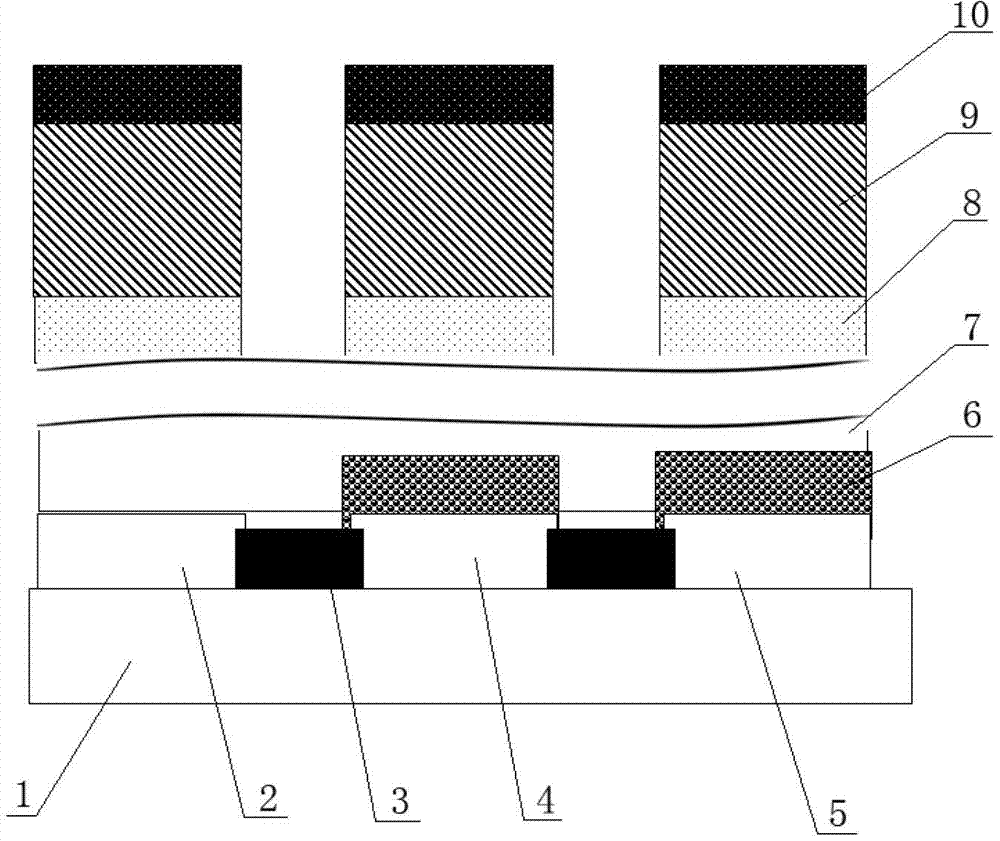

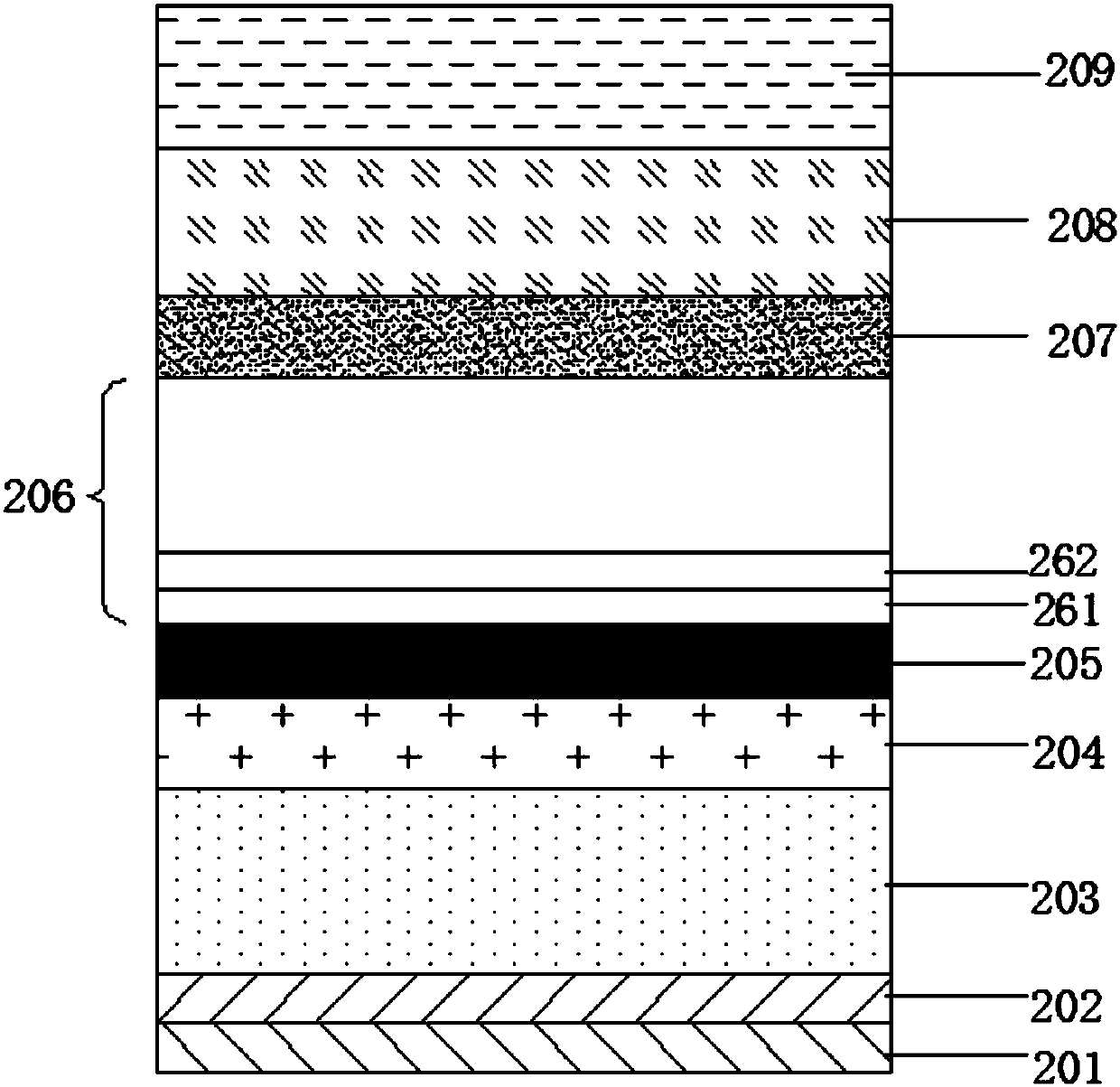

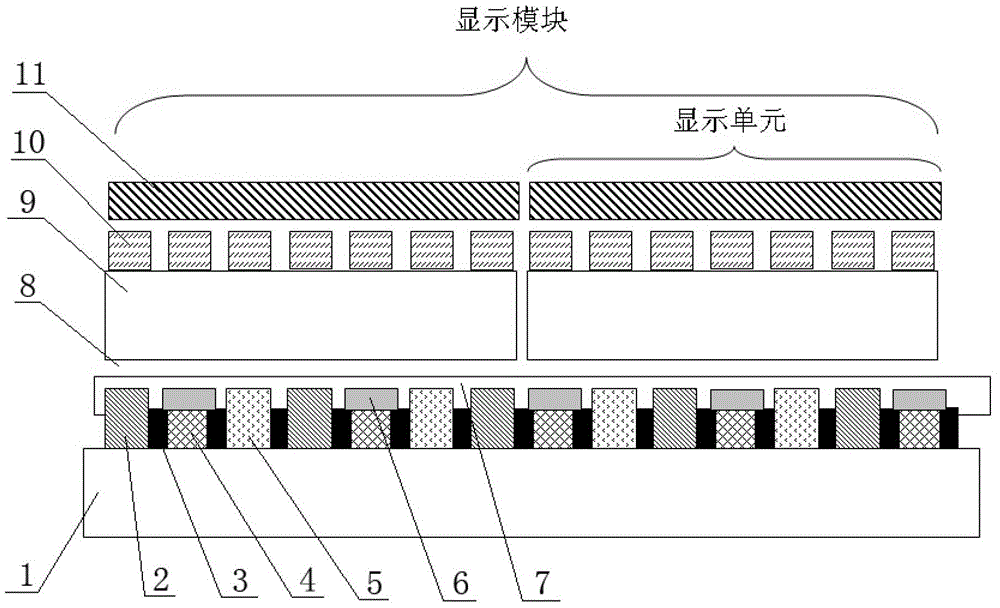

Top-light-emission full-color organic light emitting diode (OLED) display

InactiveCN102931213AImprove yield rateImprove absorption efficiencySolid-state devicesSemiconductor/solid-state device manufacturingManufacturing technologyDisplay device

The invention relates to a top-light-emitting full-color organic light emitting diode (OLED) display, which comprises a filter substrate, a color conversion film layer, an OLED light emitting device and a driving unit. The display is characterized in that the color conversion layer is a green color conversion film layer and covers light transmittance electrode layers of the OLED light emitting device corresponding to the green filter film layer; and under the condition of power-on, the luminescence spectrum of electroluminescence generated by the OLED light emitting device in a power-on state comprises a blue-color light emitting component of which the CIE color coordinate Y value is less than 0.55 and a red color light emitting component of which the CIE color coordinate X value is more than 0.64. The conventional manufacturing method and the conventional manufacturing process for the full-color OLED display having various color conversion modes are developed and created and a novel technology for manufacturing the top-light-emission full-color OLED display is creatively provided; and the top-light-emission full-color OLED display manufactured by the technology has the advantages of high fineness, high yield and the like and is favorable for improving the total manufacturing cost performance of the display.

Owner:李崇

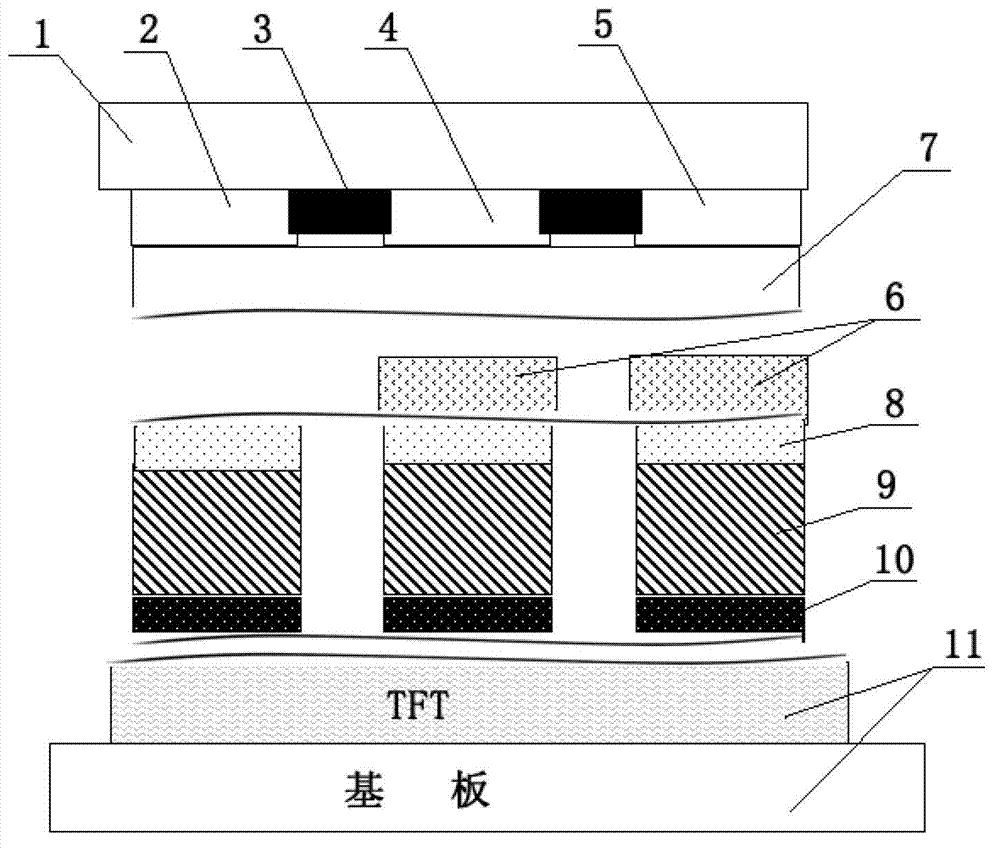

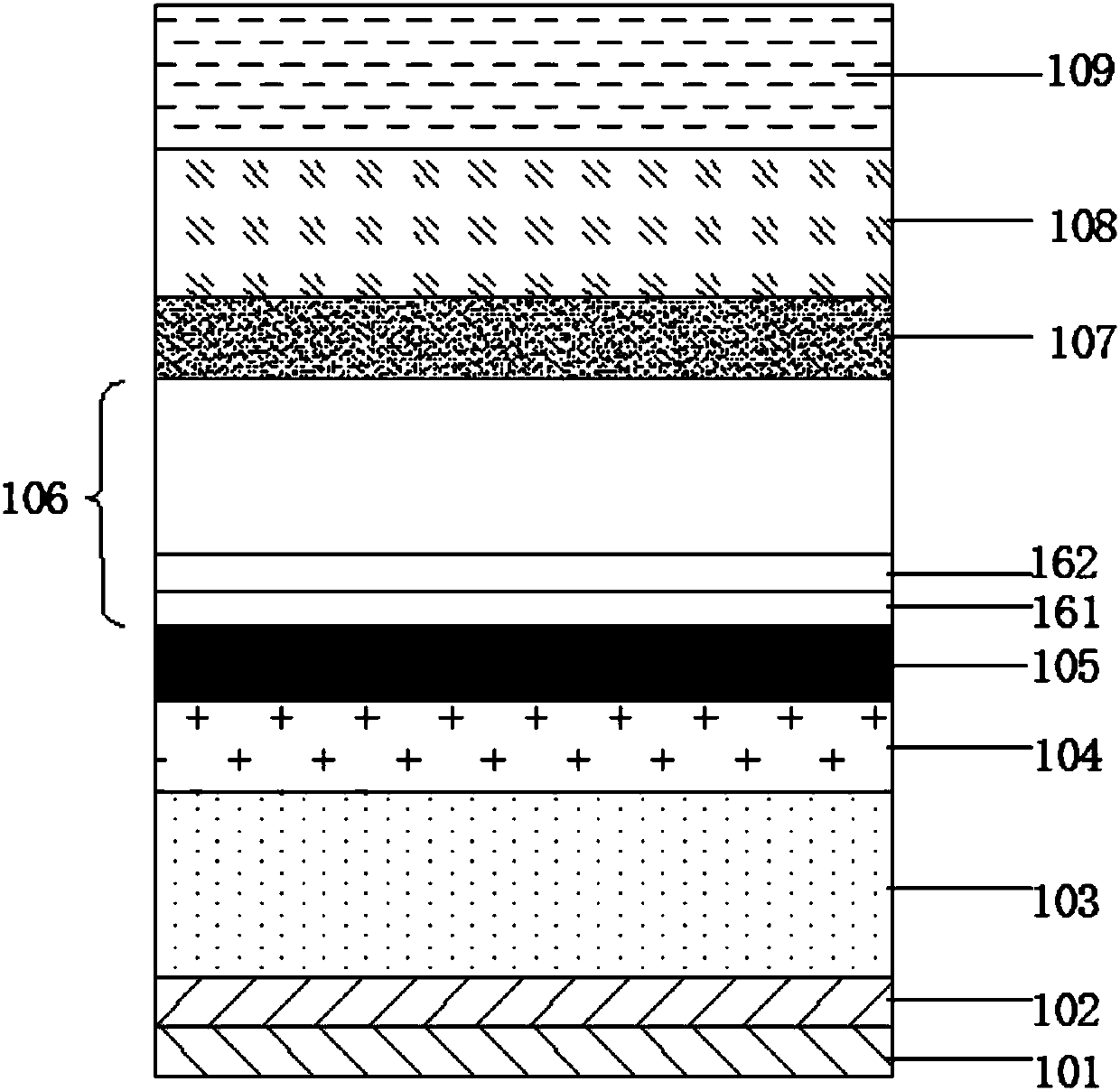

Full-color organic light emitting diode (OLED) display

ActiveCN102856350AImprove performanceImprove yield rateSolid-state devicesSemiconductor/solid-state device manufacturingElectricityDisplay device

The invention relates to a full-color organic light emitting diode (OLED) display which comprises a color conversion substrate, an OLED luminous device and a driving unit for driving the OLED luminous device to illuminate, and is characterized in that a green color conversion film layer covers a green light filter film layer; the OLED luminous device is arranged on a red light filter film layer, the green light filter film layer, a blue light filter film layer, a black matrix grid film layer and color conversion film layers; under the condition of power on, the OLED luminous device can produce electroluminescence; and a luminous spectrum of electroluminescence comprises at least two different types of blue luminous components with CIE color coordinate Y values less than 0.55 and at least one red luminous component with a CIE color coordinate X value more than 0.64. The full-color OLED display has the advantages of high precision, high yield, large size and the like and is favorable for improving the total manufacturing cost performance.

Owner:JIANGSU SUNERA TECH CO LTD

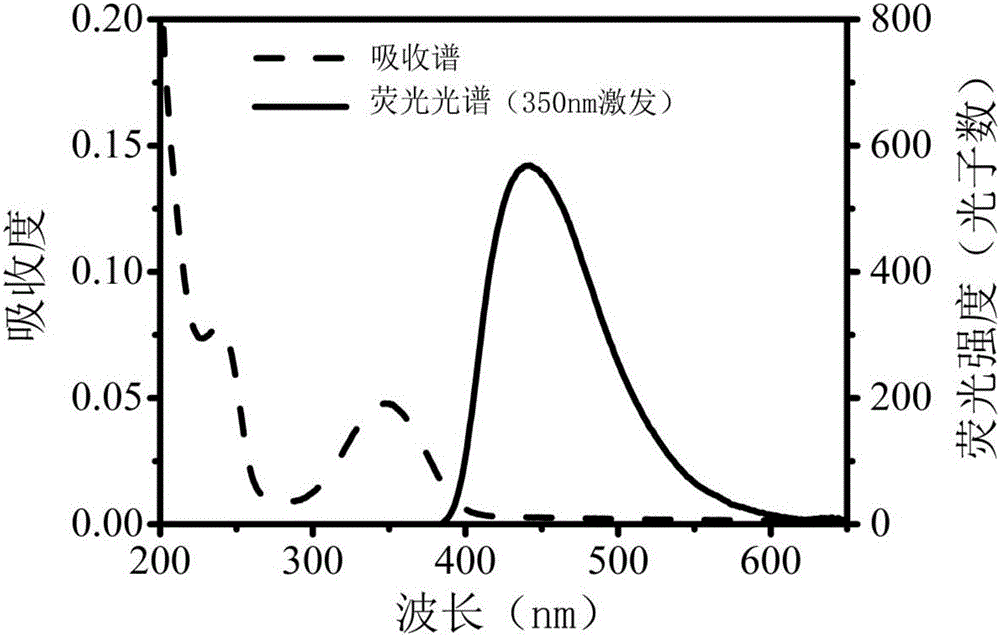

Self-supporting film provided with microstructure surface and preparation method thereof

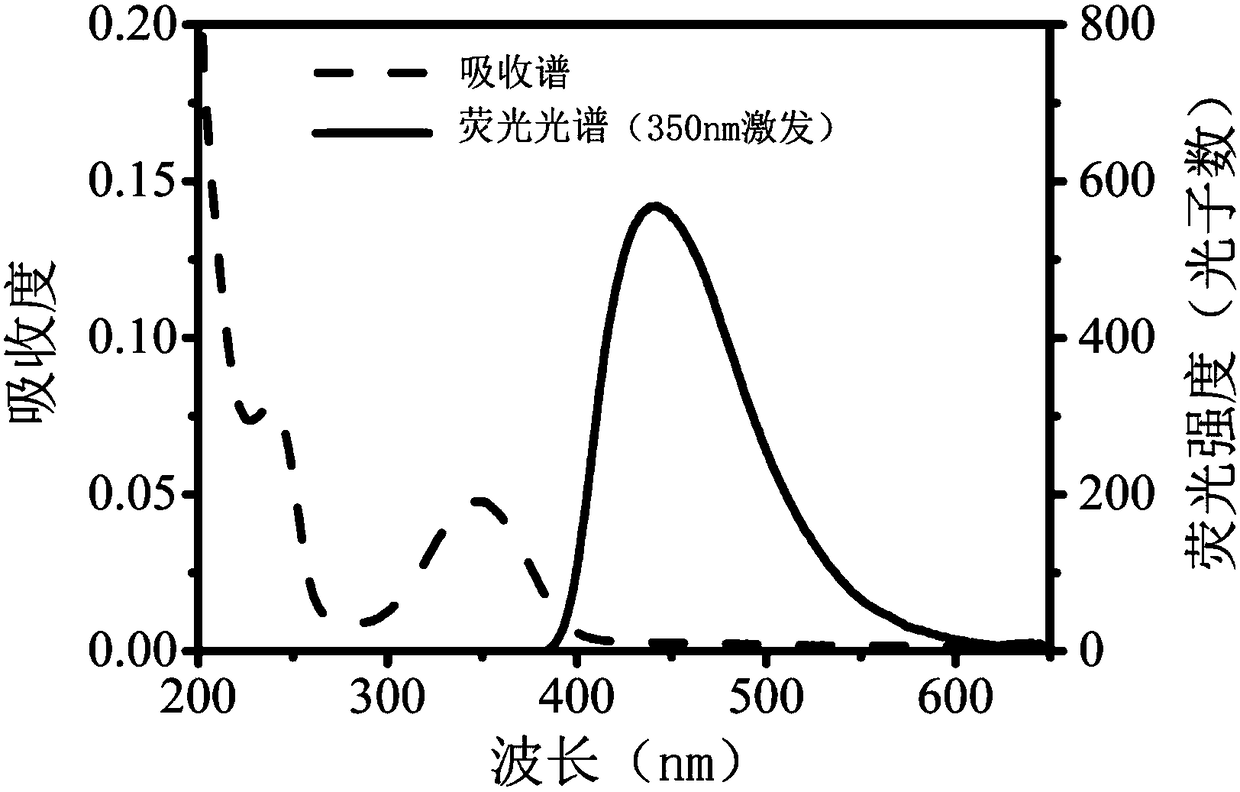

ActiveCN106190101AIncrease the number of photonsHigh quantum yieldNanoopticsLuminescent compositionsQuantum yieldQuantum dot

The invention provides a self-supporting film provided with a microstructure surface and preparation method thereof in the technical field of fluorescence quantum solutions. Firstly, a fluorescence quantum solution and a PVA solution are respectively prepared, then the fluorescence quantum solution is added to the PVA solution for even mixing, and a fluorescence quantum / PVA mixed solution is obtained; then, the fluorescence quantum / PVA mixed solution is added to a mold provided with a microstructure at the bottom, finally heat curing is performed to prepare the self-supporting film provided with the microstructure surface. By arranging the microstructure on the surface of the fluorescent quantum dot self-supporting film, the solid-state fluorescence quantum yield and the corresponding light conversion efficiency are improved. The self-supporting film can be widely applied in lots of fields of photoelectric devices, biological science and the like.

Owner:SHANGHAI JIAO TONG UNIV

Epitaxial growth method of LED capable of improving luminous efficiency

ActiveCN107564999AImprove luminous efficiencyImprove antistatic performanceSemiconductor devicesElectron blocking layerBiology

The invention discloses an epitaxial growth method of an LED capable of improving the luminous efficiency. The method sequentially comprises the steps of treating a substrate; growing a low-temperature buffer layer GaN; growing an undoped GaN layer; growing a Si-doped N-type GaN layer; growing an InAlN:Mg thin barrier layer; alternately growing an InxGa(1-x)N / GaN luminous layer; growing an AlGaN:Mg thin barrier layer and an InGaAlN superlattice electron blocking layer; growing a P-type AlGaN layer; growing a Mg-doped P-type GaN layer; and cooling. Through the epitaxial growth method of the LED, the problem of a luminous efficiency droop (efficiency droop) under heavy current injection in existing epitaxial growth of the LED is solved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

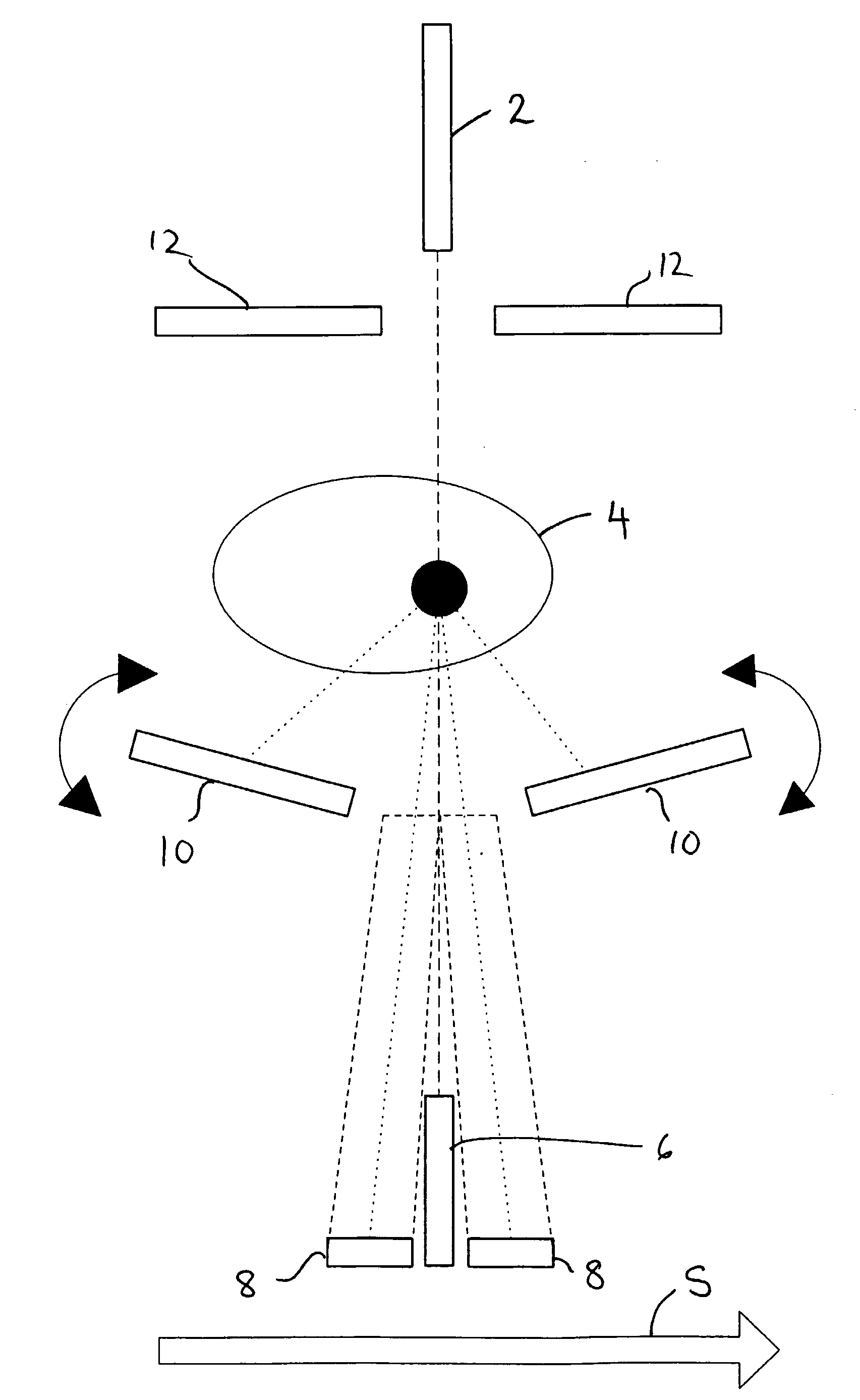

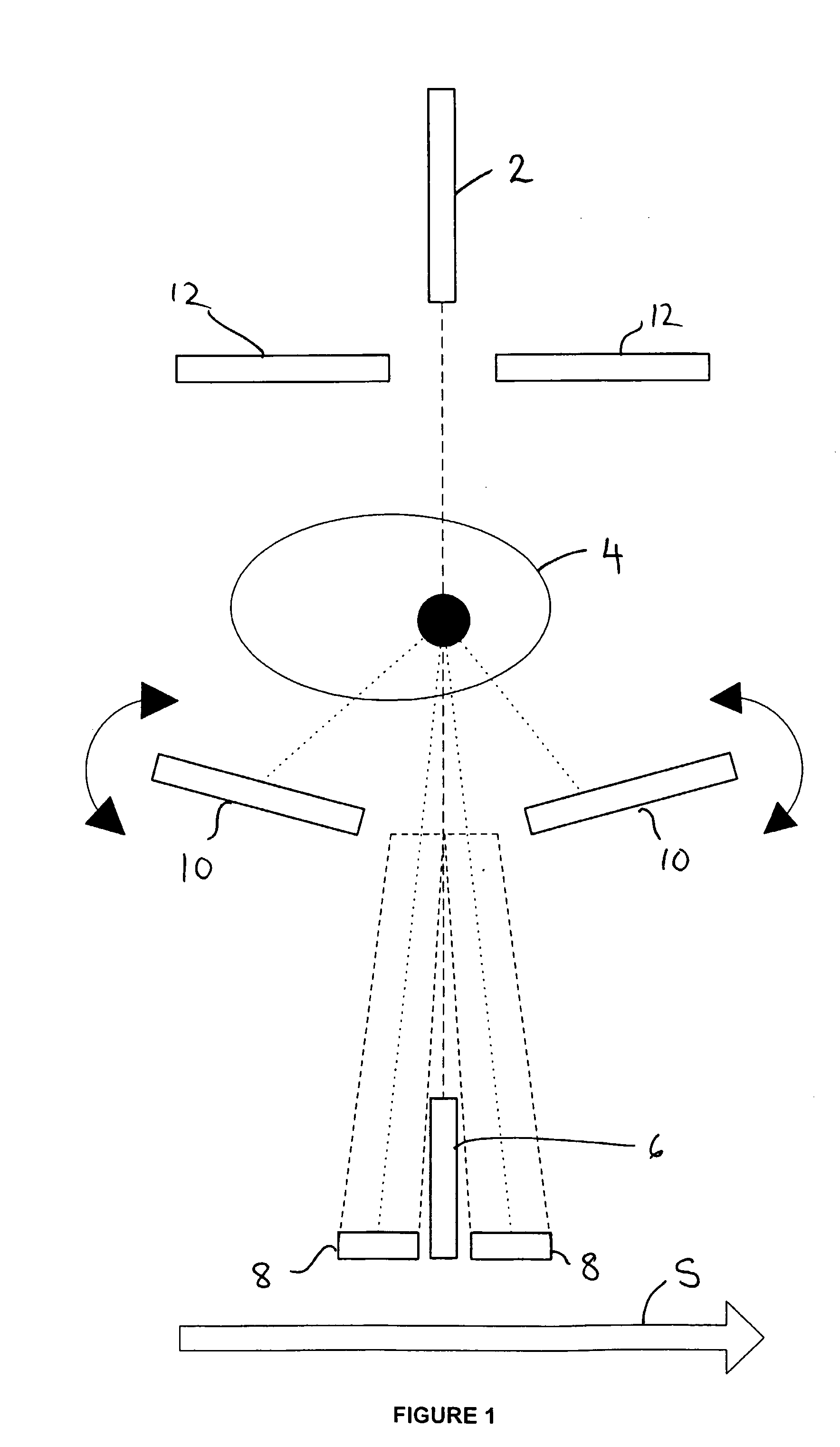

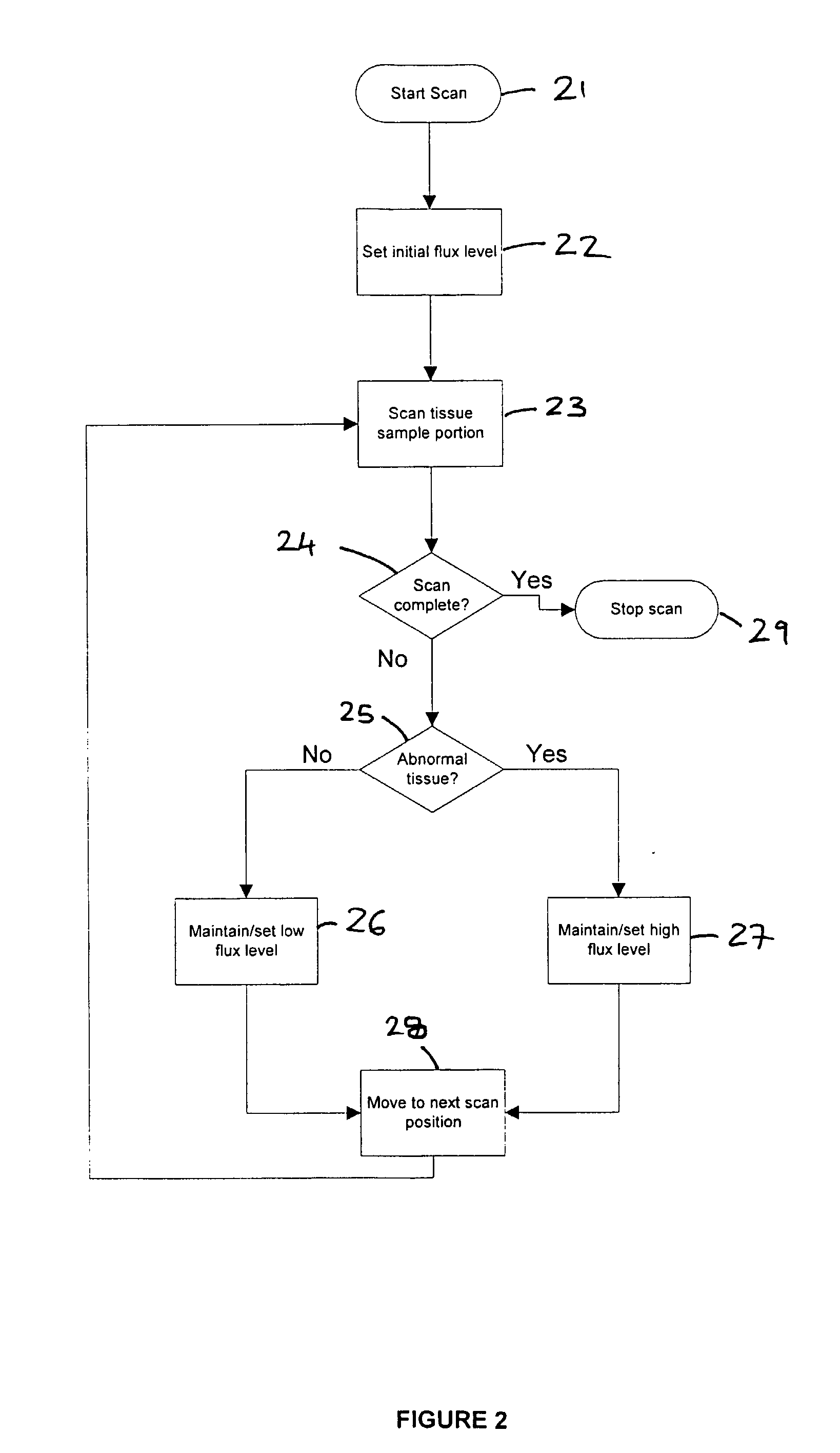

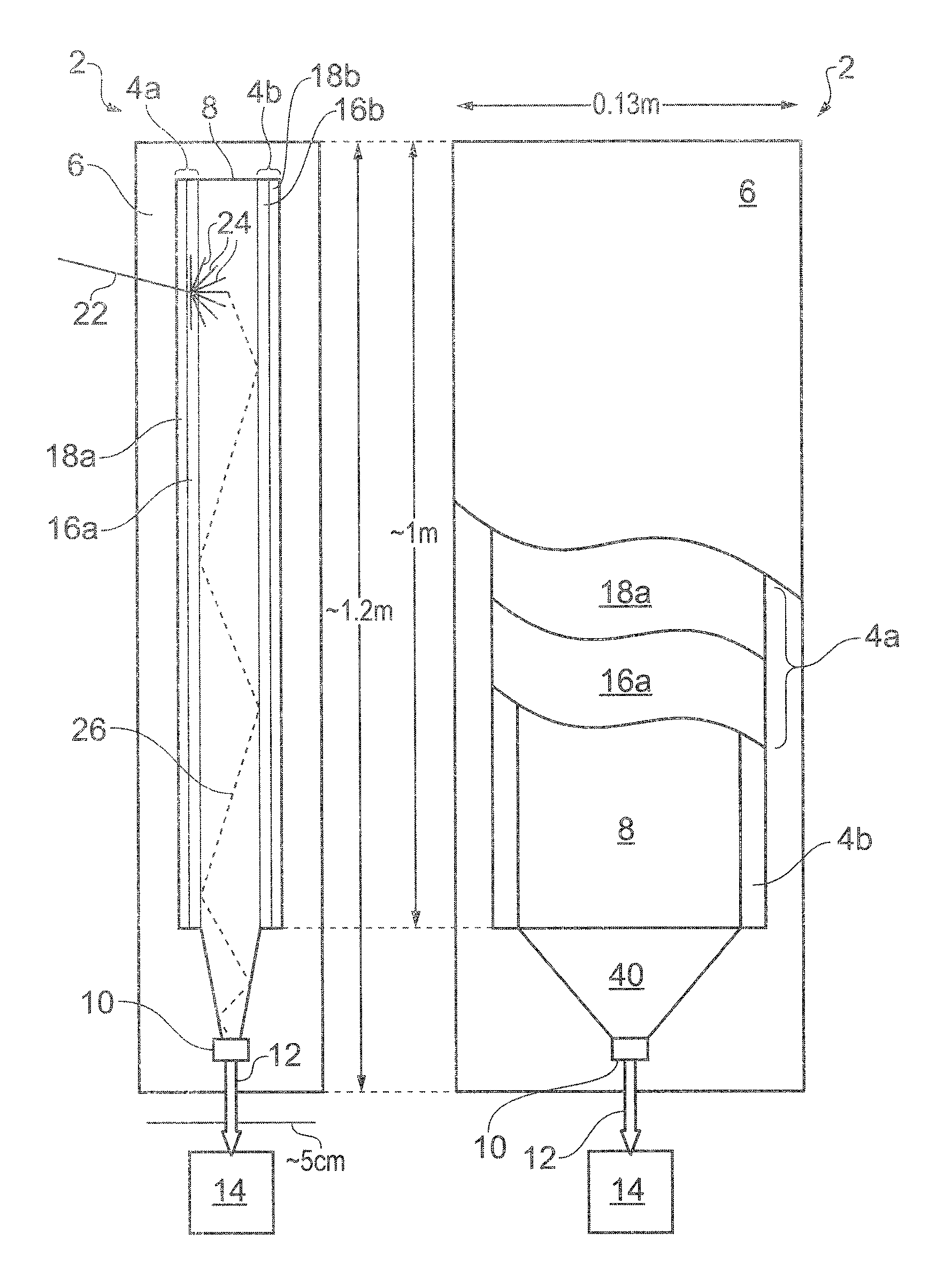

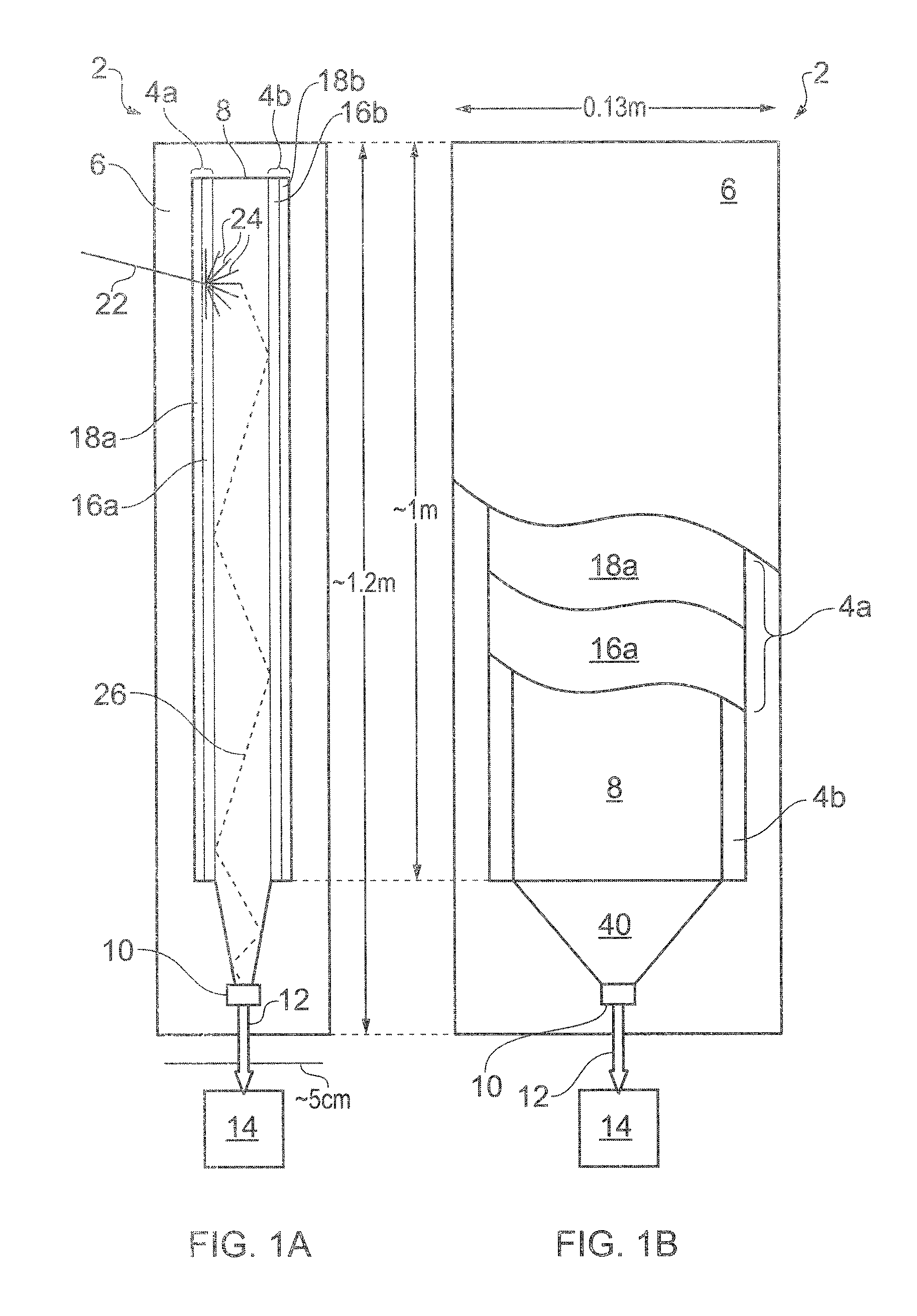

Method and Apparatus for Irradiating Body Tissue

InactiveUS20080118027A1Add information contentIncrease the number of photonsBioreactor/fermenter combinationsBiological substance pretreatmentsX-rayTissue sample

A method for irradiating a biological tissue sample is provided, the method comprising: irradiating a portion of a biological tissue sample with a penetrating radiation beam for a first exposure period; subsequently irradiating the same or an adjacent biological tissue portion with a penetrating radiation beam for a second exposure period; the radiation dose incident on the tissue sample during the second exposure period being higher than the dose during the first exposure period. Also provided is an apparatus operative in accordance with the method. The method and apparatus have particular application in the characterisation of body tissue by x-ray diffraction, both in vitro and in vivo.

Owner:GAVED MATTHEW +1

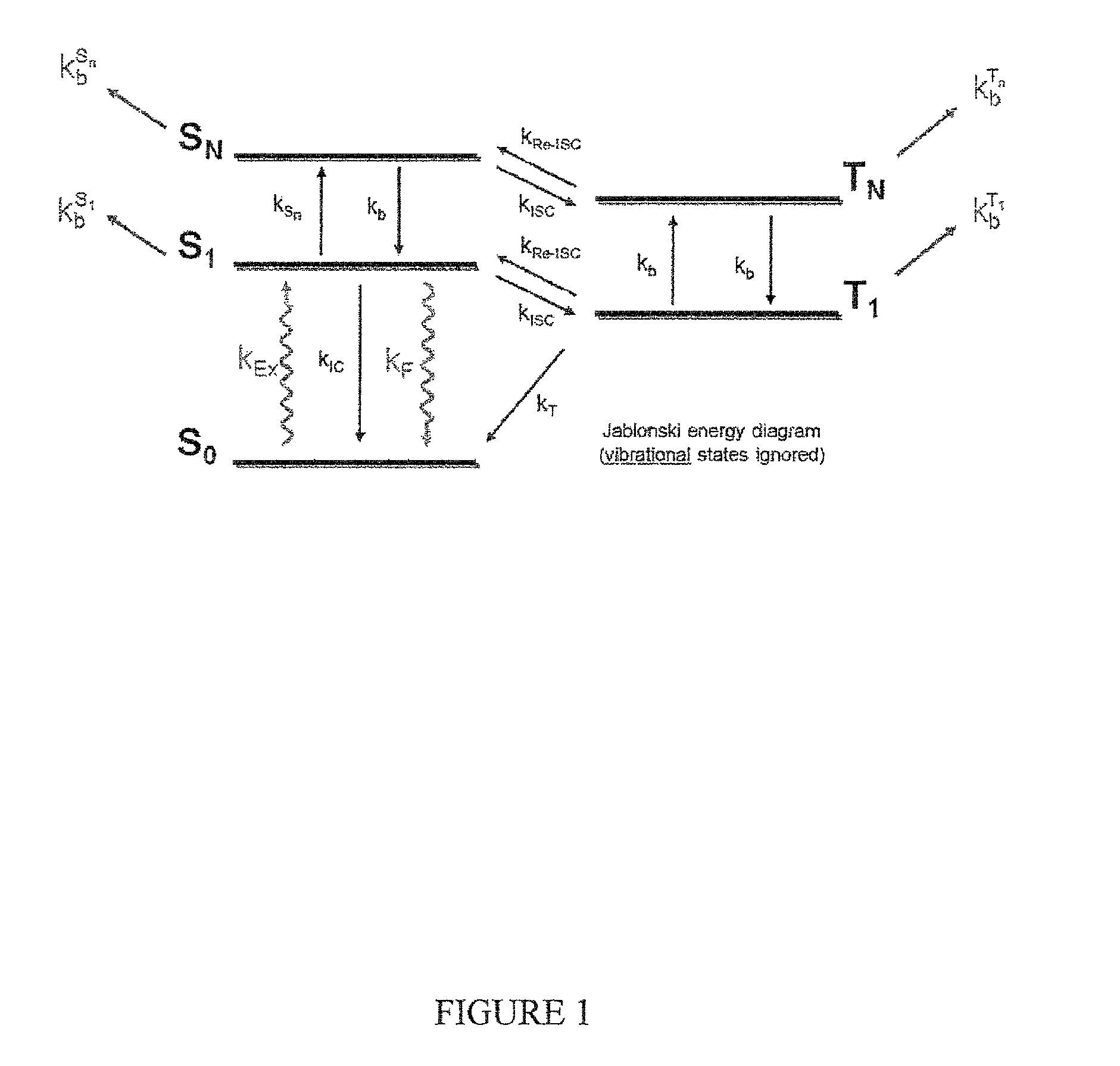

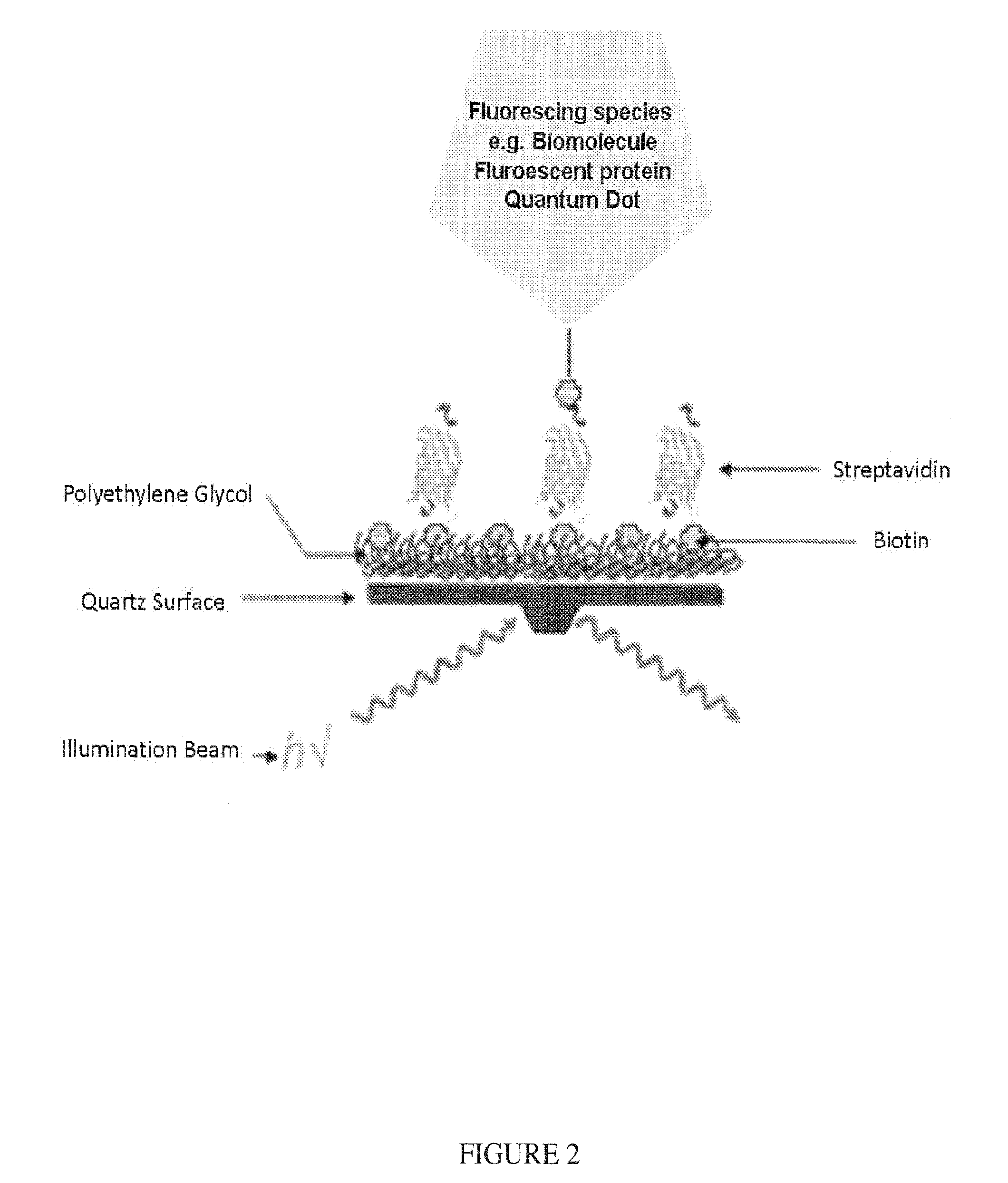

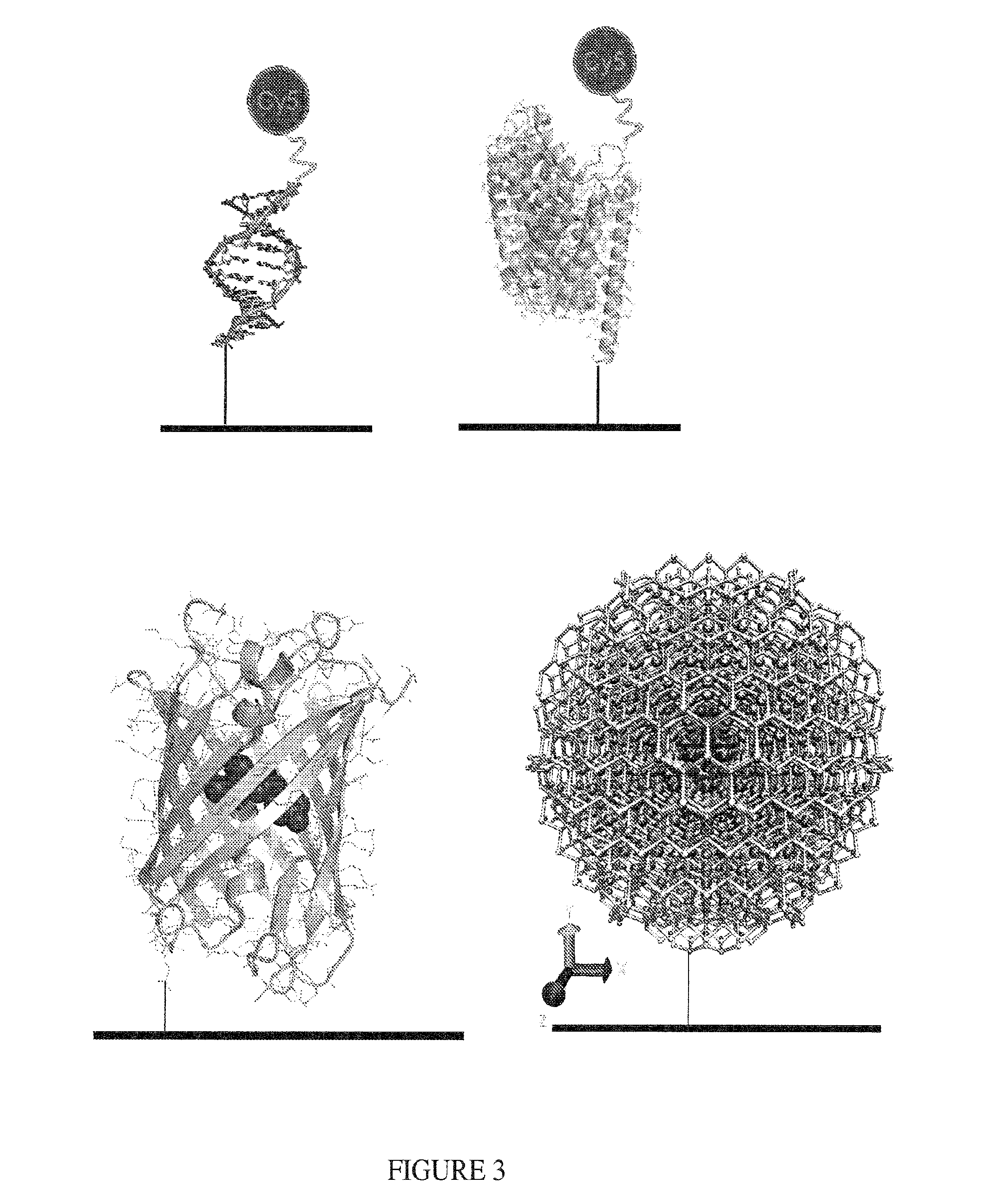

Methods and compositions for altering photophysical properties of fluorophores via proximal quenching

ActiveUS8945515B2Increase the number of photonsIncrease and optimize effective fluxUltrasonic/sonic/infrasonic diagnosticsSurgeryFluorophoreFrequency of occurrence

The invention is directed to fluorophore-containing compositions and configurations wherein proximity between the fluorophore and one or more protective agents (PAs) modifies the lifetime of fluorescent and / or dark states, their frequency of occurrence, and the total lifetime of fluorescence in order to appropriately modify the photophysical characteristics of the fluorophore. The invention is also directed to methods that utilize these compositions and configurations.

Owner:CORNELL UNIVERSITY

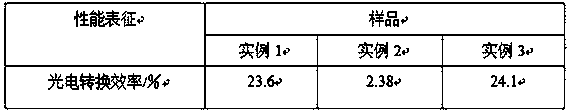

Preparation method of CIGS solar cell film buffer layer material

InactiveCN109285919AHigh quality factorLow dielectric lossFinal product manufacturePhotovoltaic energy generationElectronic band structureFilm material

The invention relates to a preparation method of a CIGS solar cell film buffer layer material, and belongs to the technical field of cell materials. The technical scheme of the invention adopts a sol-gel method, and a buffer layer is introduced on the surface of a CIGS film. Meanwhile, a role of resistance is played through reducing the interface state, so that internal short circuit of the cell is prevented, and the dielectric performance and photoelectric conversion efficiency of the film material are effectively improved. In addition, the CIGS solar cell film buffer layer material adopts the buffer layer and is coated by a precursor gel structure and dried, so that the bonding strength of the material on the surface is effectively improved. Through the mutual matching of an energy bandstructure between the buffer layer material and an absorption layer, a film with moderate thickness is formed on the basis. The damage imposed on the absorption layer by the preparation of a subsequent window layer material is reduced through improving the number of photons of the absorption layer, so that the surface conductivity and photoconductivity of the buffer layer material are effectivelyimproved, and photon-generated carriers are enabled to be outputted to an external circuit in time.

Owner:王敏

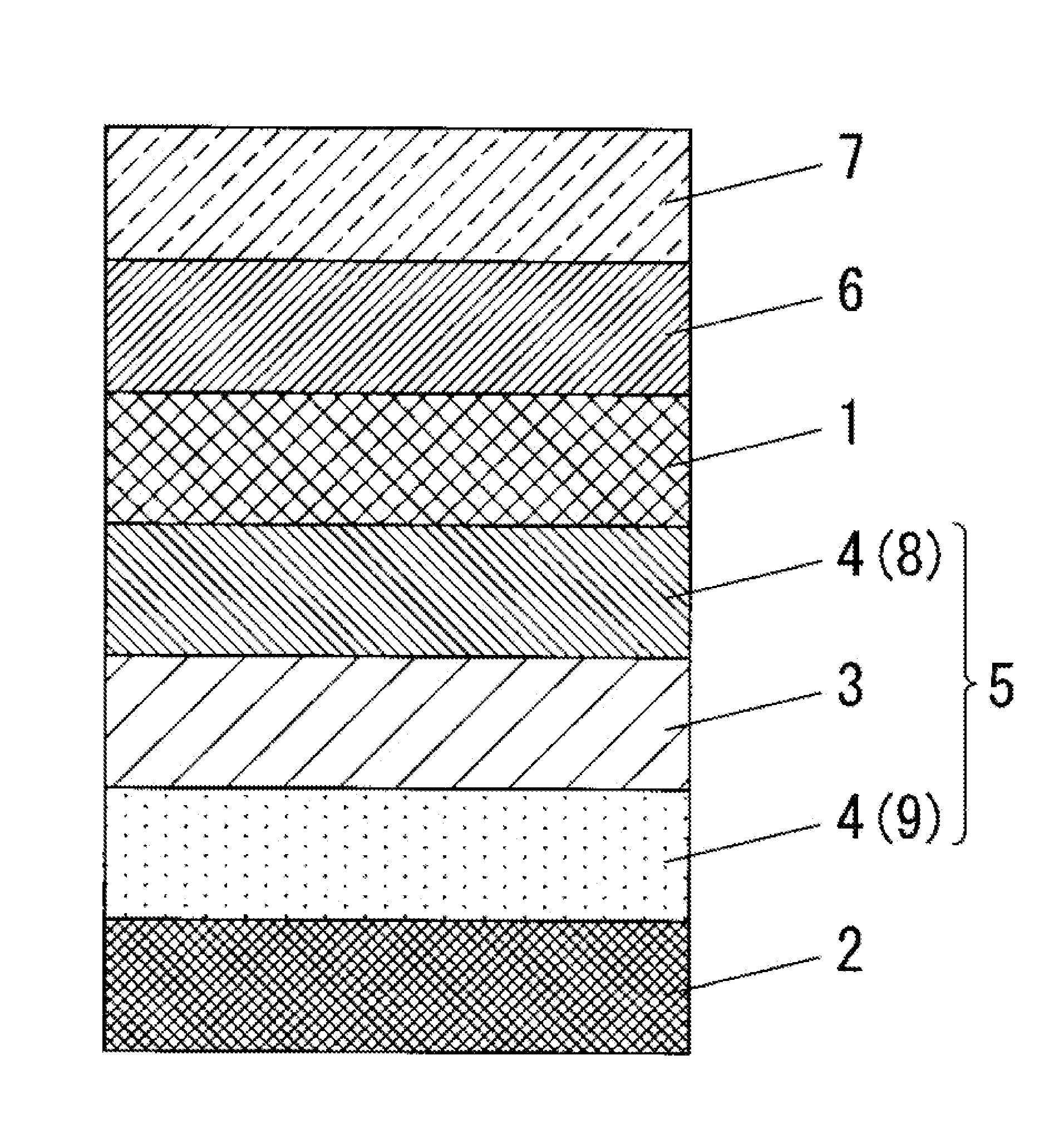

Organic electroluminescence device

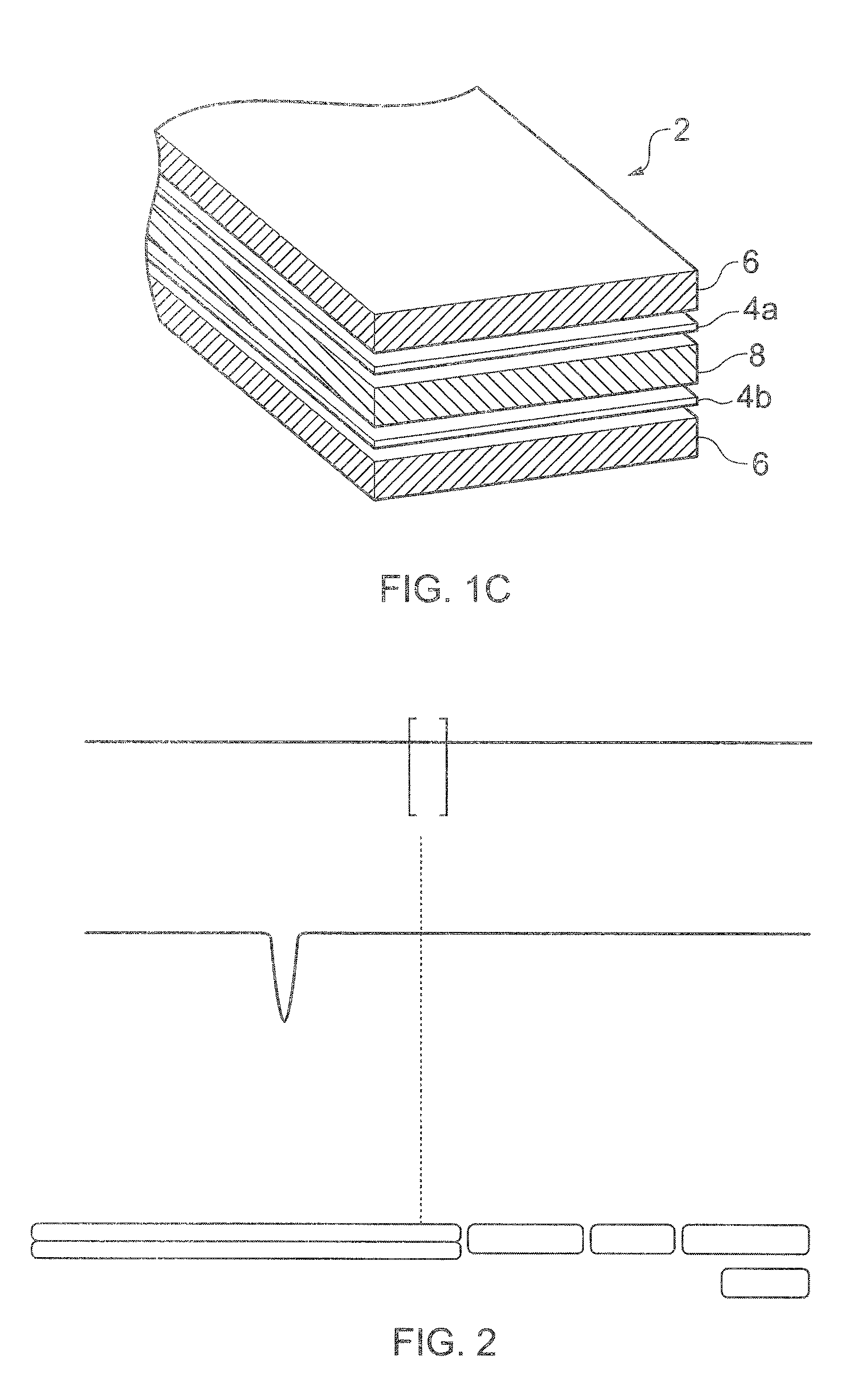

ActiveUS8357930B2Convenient lightingSpeed up the conversion processDischarge tube luminescnet screensLamp detailsAttenuation coefficientRefractive index

An organic electroluminescence device comprises a light transmissive substrate, a light scattering region which is disposed on the light transmissive substrate, and a light emissive layer having a luminescent point. The luminescent point is spaced from the light reflective electrode by a distance of d which satisfies the following equation:nd=a×λ4(2+ϕπ)whereinϕ=tan-1{2(n1k2-n2k1)n12-n22+k12-k22}.λ is a wavelength of a specific light emitted from said light emissive layer.n is a refractive index of a layer disposed between the luminescent point of the light emissive layer and the light reflective electrode, with respect to the wavelength of λ.n1 and k1 are respectively a refractive index and an attenuation coefficient of the layer disposed between the luminescent point of the light emissive layer and the light reflective electrode, and is in contact with said light reflective electrode, with respect to the wavelength of λ.n2 and k2 are respectively a refractive index and an attenuation coefficient of the light reflective electrode, with respect to the wavelength of λ.a is a value that satisfies a relation of “1.28<a≦−5.56×norg / nEML+7.74”norg is a refractive index of the layer disposed which is located between the luminescent point of the light emissive layer and the light reflective electrode and which is in contact with the light emissive layer, with respect to the wavelength of λ.nEML is a refractive index of the light emissive layer with respect to the wavelength of λ.

Owner:SAMSUNG DISPLAY CO LTD

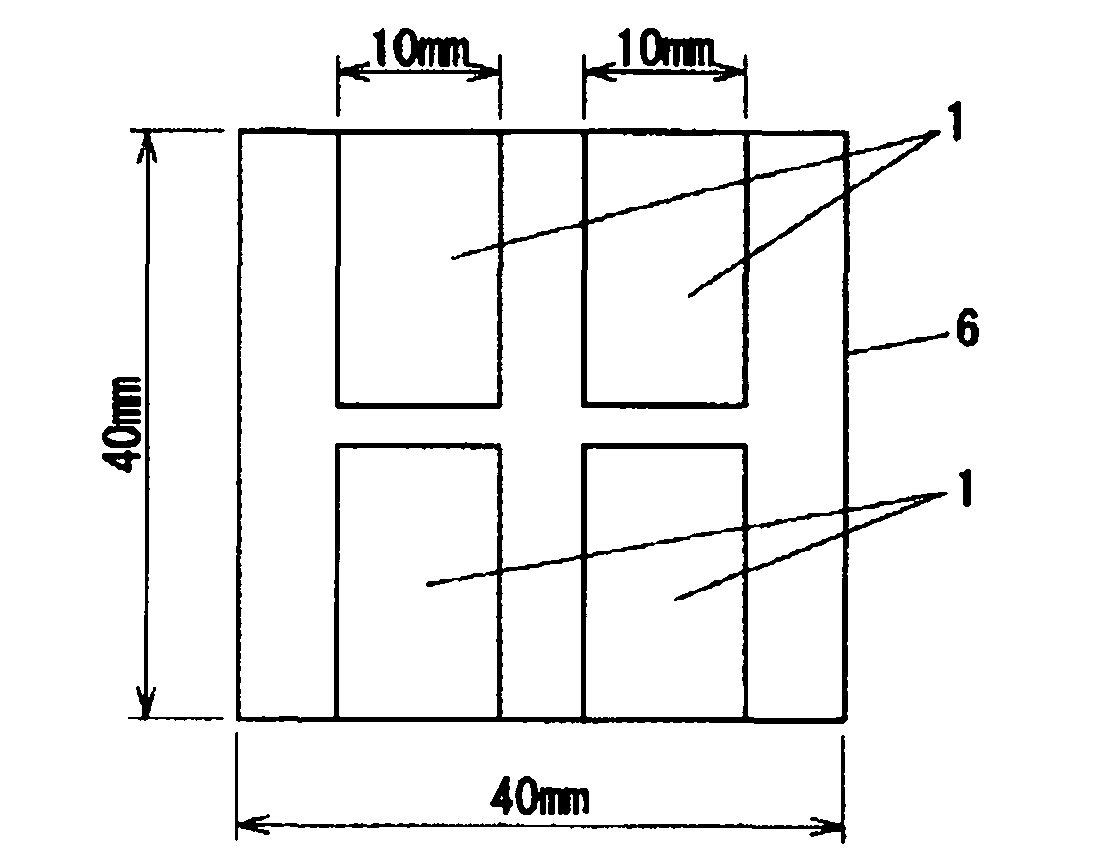

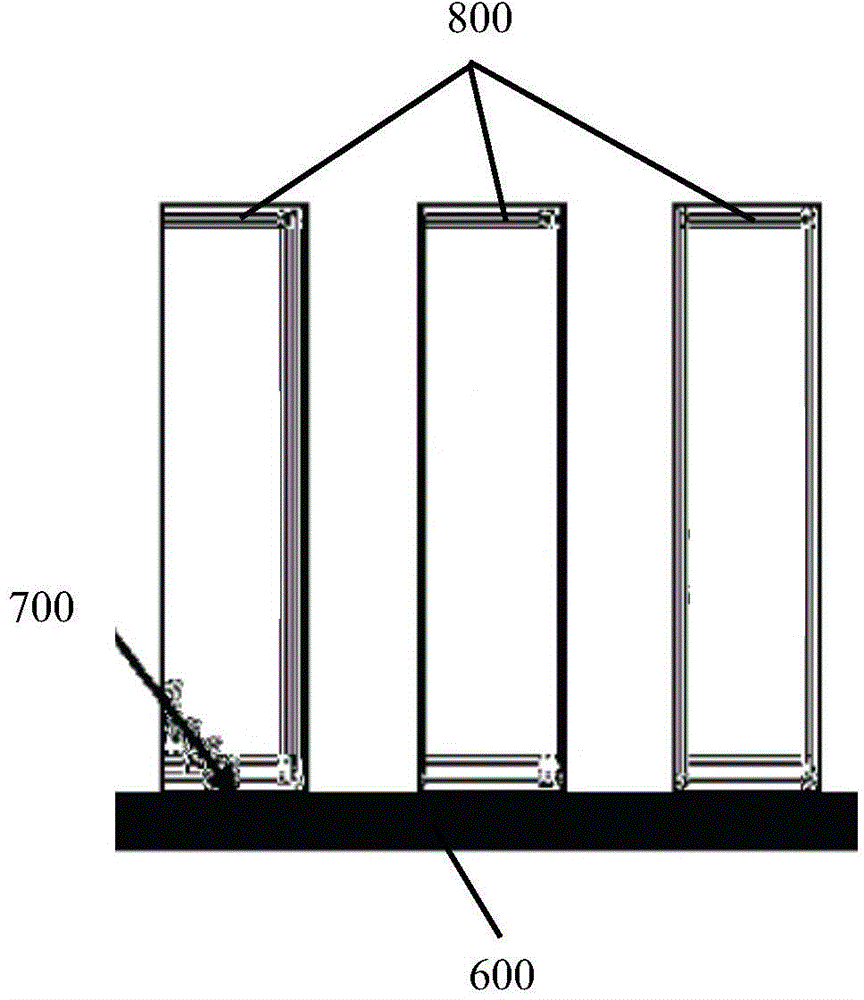

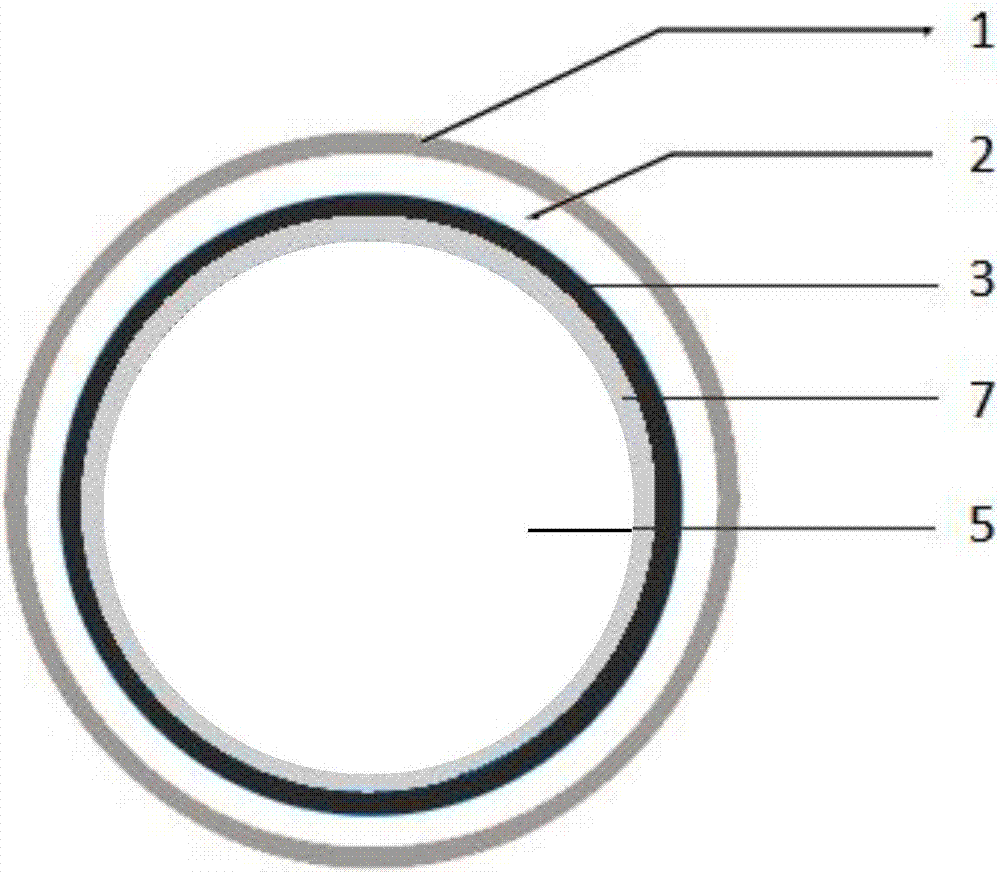

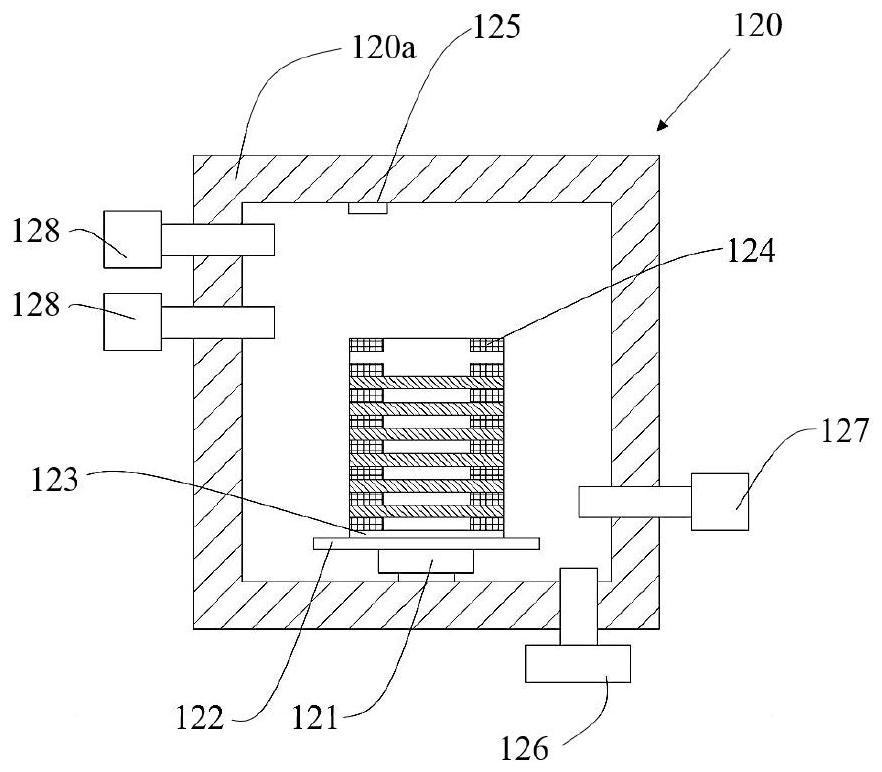

Array crystal module and machining method thereof

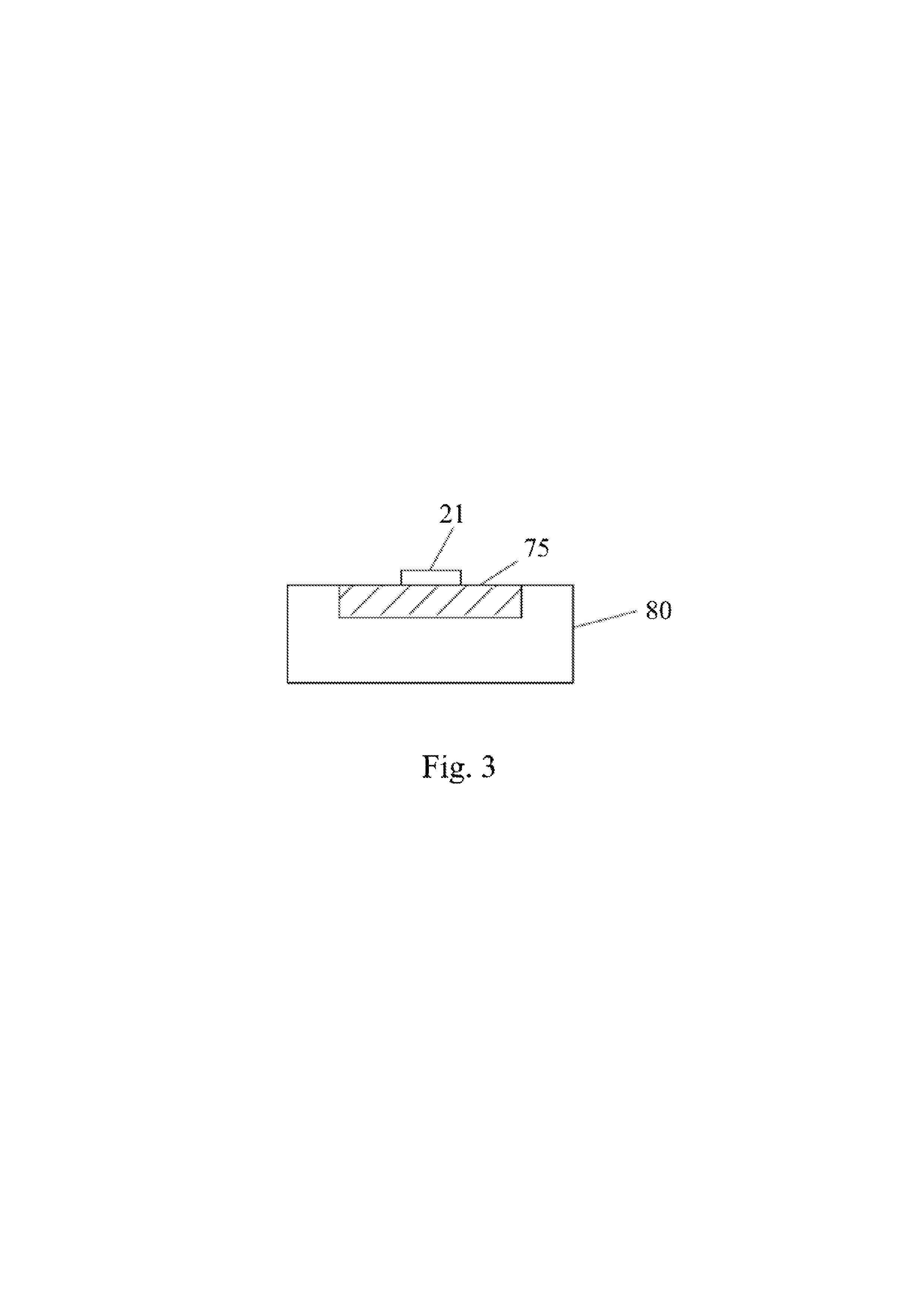

ActiveCN104422950AReduced light output surfaceSolving the problem of light output lossSolid-state devicesX/gamma/cosmic radiation measurmentComputer modulePhotoelectric conversion

An array crystal module comprises a plurality of unit crystal strips (10). The exterior three-dimensional shape of the array crystal module is a frustum (12) or a combination of a right quadrangular prism (11) and the frustum (12), and the frustum (12) is used to be coupled with a photoelectric device (20). The frustum (12) comprises a first bottom face coupled with the photoelectric device (20) and a first top face opposed to the first bottom face, and the area of the first bottom face is smaller than that of the first top face. A fabrication method of the array crystal module includes: fabricating a crystal strip blank to obtain a unit crystal strip, performing the die cutting to obtain a unit crystal strip in the shape of a frustum or a unit crystal strip in the shape of a combination of a right quadrangular prism and a frustum according to a set obliquity and the thickness of the right quadrangular prism part, and assembling the unit crystal strips together to form an array crystal module. The above array crystal module, on the premise that the detection efficiency is guaranteed, can solve the problem of the light output loss of the crystal caused by the fact that the effective detection area of a photoelectric conversion device is smaller than a packaging area, thereby guaranteeing the sensitivity and performance of a detector.

Owner:RAYCAN TECH CO LTD SU ZHOU

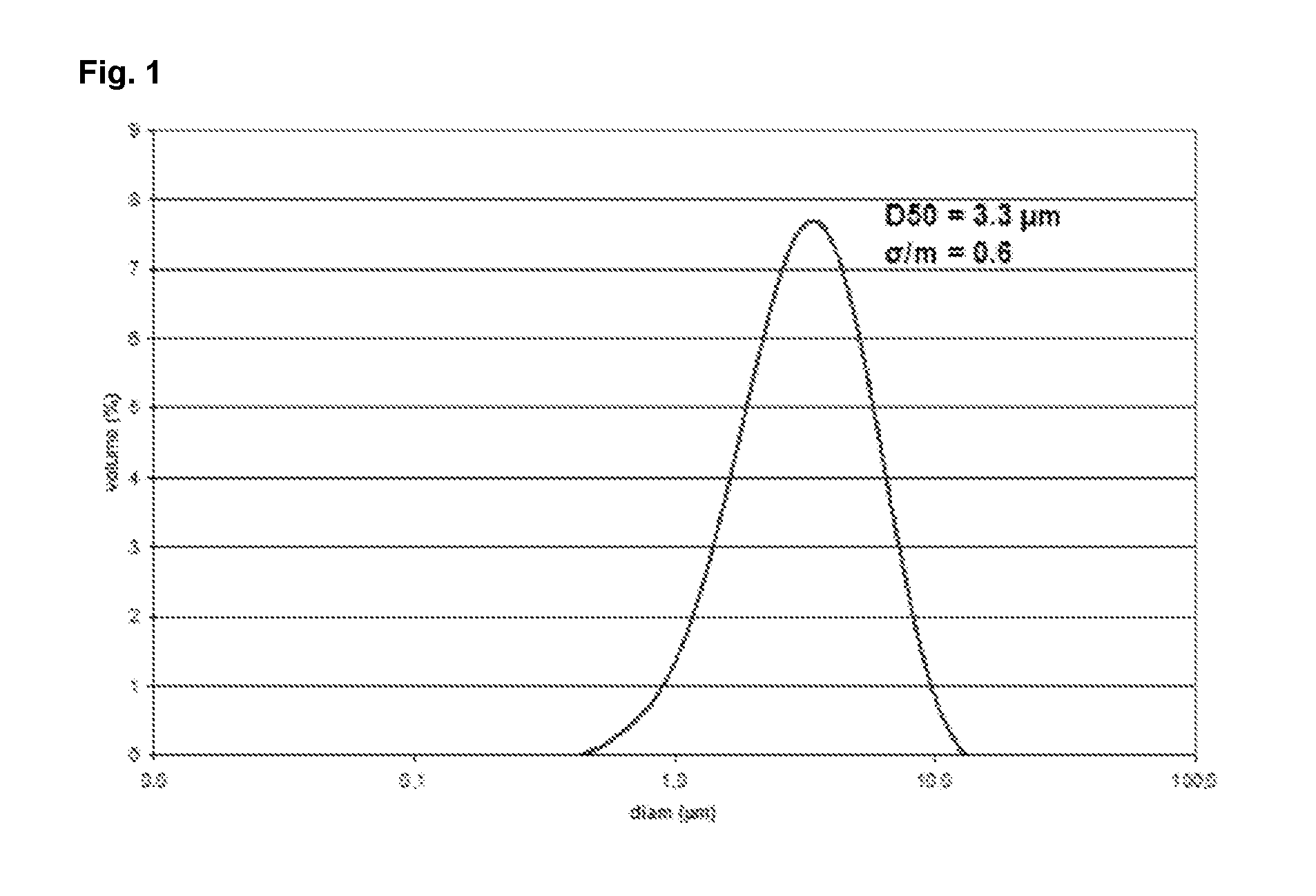

Luminescent composite comprising a polymer and a luminophore and use of this composite in a photovoltaic cell

InactiveUS20160222289A1Increase absolute conversion efficiencyIncrease the number of photonsSolid-state devicesPhotovoltaic energy generationETFERare-earth element

The composite of the invention comprises (a) a polymer selected from ethylene / vinyl acetate, polyethylene terephthalate, ethylene tetrafluoroethylene, ethylene trifluorochloroethylene, perfluorinated ethylene-propylene, polyvinyl butyral, polyurethane and silicones; (b) an inorganic phosphor based on at least one element selected from rare earth elements, zinc and manganese, which has an external quantum efficiency of greater than or equal to 40% for at least one excitation wavelength of between 350 nm and 440 nm; an absorption of less than or equal to 10% for a wavelength of greater than 440 nm; a mean particle size of less than 1 μm; and this phosphor has an emission maximum in a range of wavelengths between 440 nm and 900 nm.

Owner:RHODIA OPERATIONS SAS

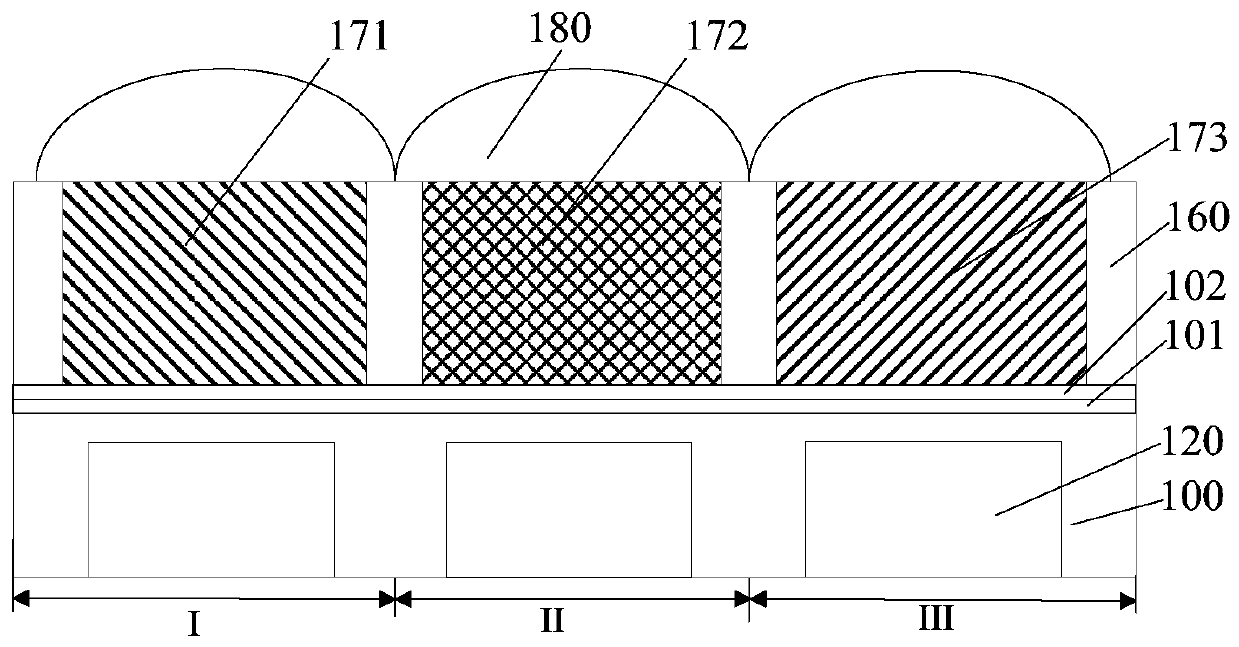

Image sensor and formation method

InactiveCN109873005AHigh sensitivityImprove photosensitivityRadiation controlled devicesSemiconductorImage sensor

The invention relates to an image sensor and a formation method. The method comprises the steps of providing a semiconductor substrate, wherein the semiconductor substrate comprises a first surface and a second surface which are opposite to each other, and the semiconductor substrate comprises a plurality of first regions; forming a conversion light-emitting material layer on a surface of the second surface at each first region of the semiconductor substrate; and forming a filtering structure on surfaces of the conversion light-emitting material layer and the second surface of the semiconductor substrate. By the method, the performance of the image sensor is improved.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

Organic electroluminescence device

ActiveUS20110121267A1Convenient lightingImprove lighting efficiencySolid-state devicesSemiconductor/solid-state device manufacturingAttenuation coefficientRefractive index

An organic electroluminescence device comprises a light transmissive substrate, a light scattering region which is disposed on the light transmissive substrate, and a light emissive layer having a luminescent point. The luminescent point is spaced from the light reflective electrode by a distance of d which satisfies the following equation:nd=a×λ4(2+φπ)whereinφ=tan-1{2(n1k2-n2k1)n12-n22+k12-k22}.λ is a wavelength of a specific light emitted from said light emissive layer.n is a refractive index of a layer disposed between the luminescent point of the light emissive layer and the light reflective electrode, with respect to the wavelength of λ.n1 and k1 are respectively a refractive index and an attenuation coefficient of the layer disposed between the luminescent point of the light emissive layer and the light reflective electrode, and is in contact with said light reflective electrode, with respect to the wavelength of λ.n2 and k2 are respectively a refractive index and an attenuation coefficient of the light reflective electrode, with respect to the wavelength of λ.a is a value that satisfies a relation of “1.28<a≦−5.56×norg / nEML+7.74”norg is a refractive index of the layer disposed which is located between the luminescent point of the light emissive layer and the light reflective electrode and which is in contact with the light emissive layer, with respect to the wavelength of λ.nEML is a refractive index of the light emissive layer with respect to the wavelength of λ.

Owner:SAMSUNG DISPLAY CO LTD

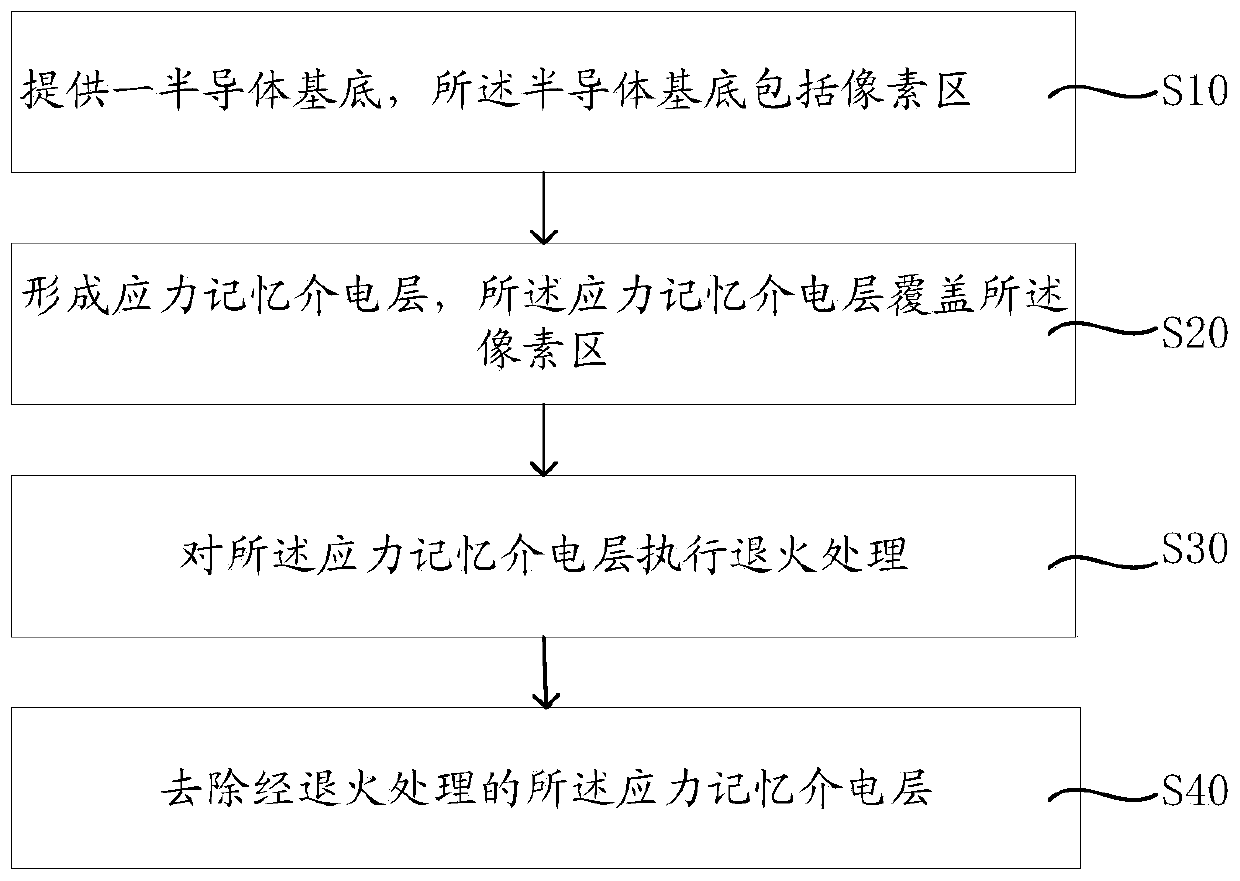

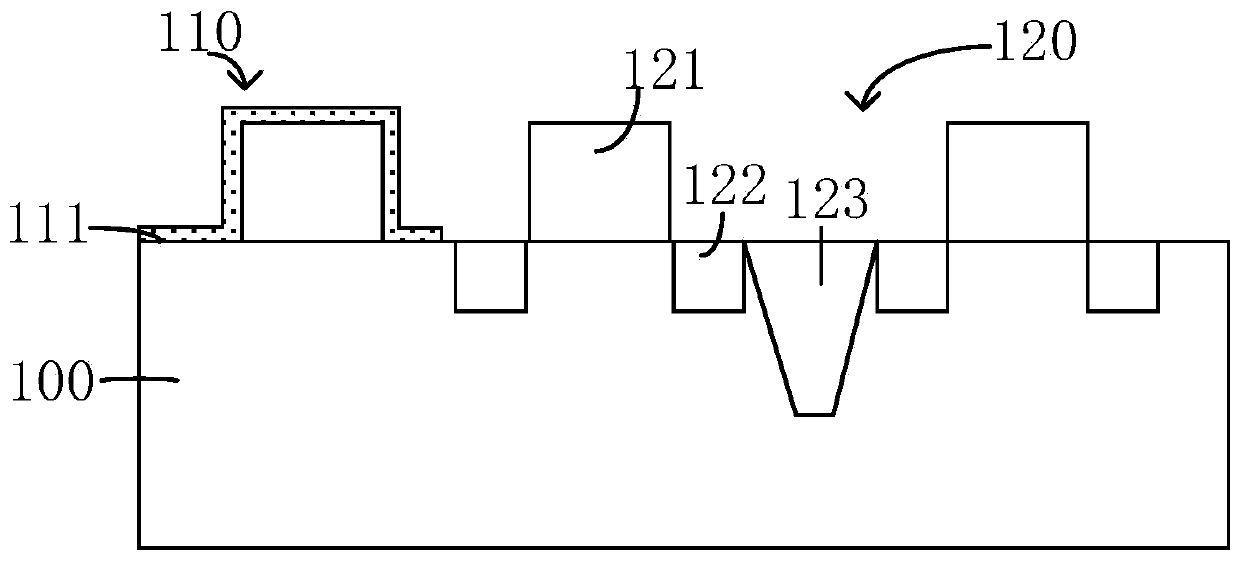

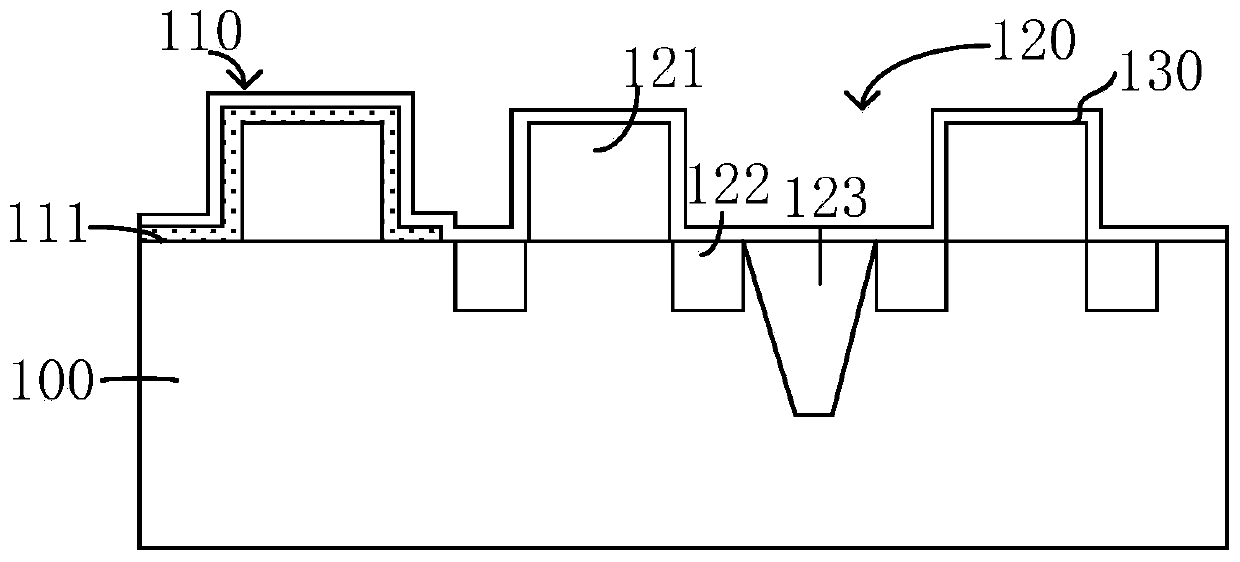

Forming method of CMOS image sensor

ActiveCN110047862AImprove mobilityIncrease the number of photonsSolid-state devicesDiodeCMOSNear infrared light

The invention provides a forming method of a CMOS image sensor, and the method comprises the steps: forming a self-aligned silicide region barrier layer, and covering a pixel region; forming a stressmemory dielectric layer, a grid electrode covering the pixel region and the pixel region, and a side wall; carrying out annealing treatment on the stress memory dielectric layer on the pixel region; and removing the stress memory dielectric layer on the pixel region. The invention also provides a CMOS image sensor, comprising a semiconductor substrate, wherein the semiconductor substrate comprisesa pixel region and a logic region; the pixel region and the logic region are each provided with a grid electrode and a side wall; a self-aligned silicide region barrier layer is formed on the pixel region, and the grid electrode and the side wall on the pixel region; a stress memory dielectric layer is arranged on the pixel region, high stress of the stress memory dielectric layer is transferredinto the pixel region through annealing, and the migration rate of electrons generated by near-infrared light can be increased in a stress mode, so that the electrons generated by near-infrared lightare increased to become signal charges, and the collection efficiency of the near-infrared light is improved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

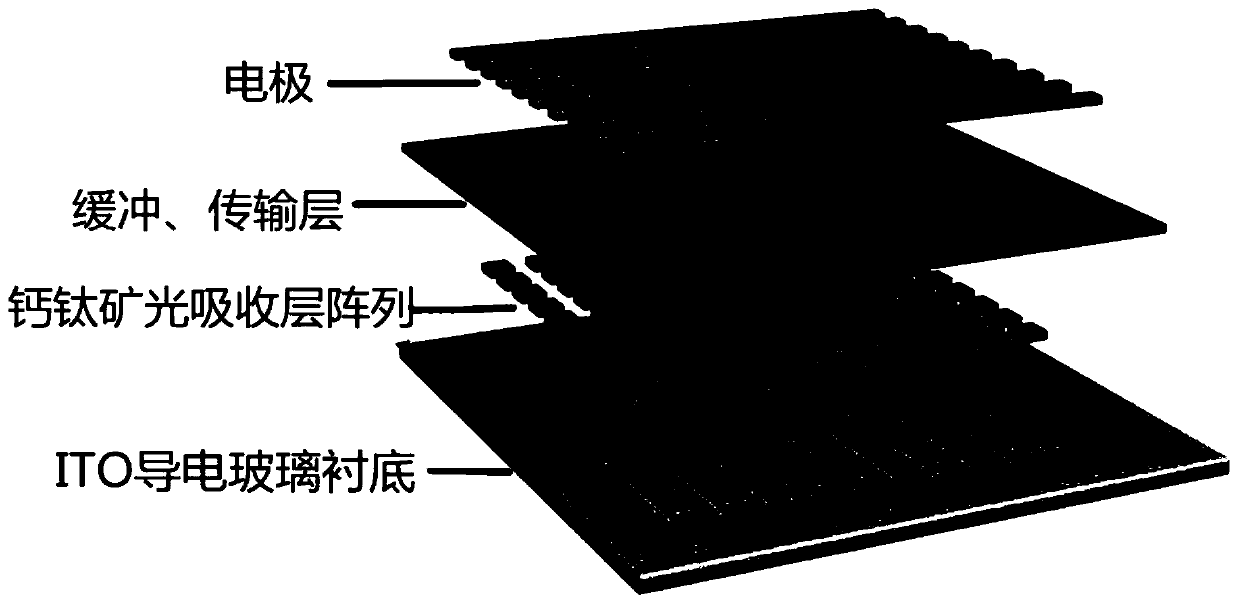

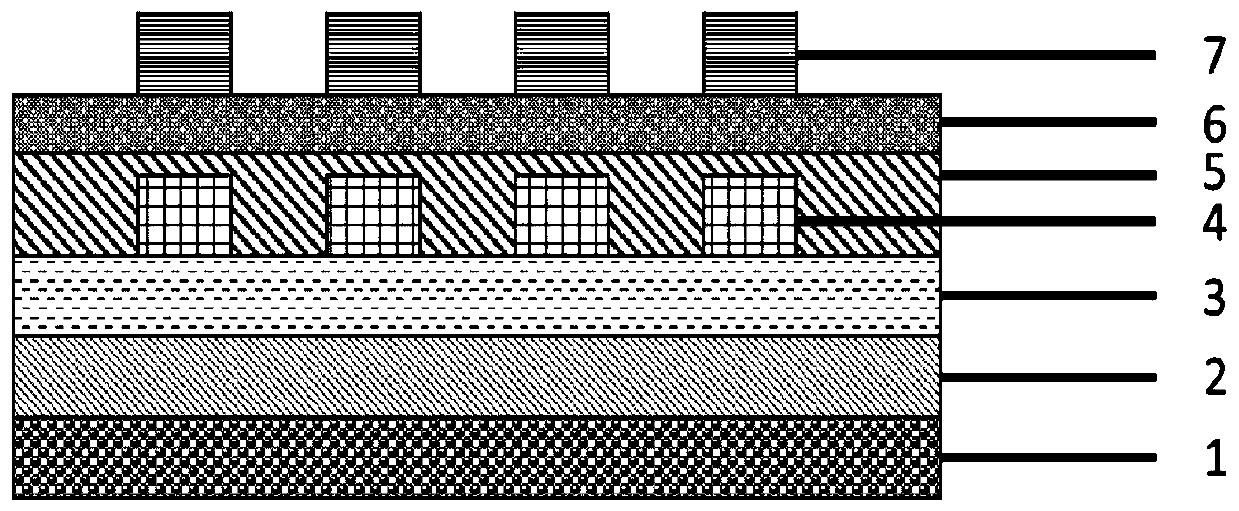

Perovskite ultraviolet photoelectric detector and preparation method thereof

PendingCN110299452AImprove performanceIncrease the number of photonsSolid-state devicesSemiconductor/solid-state device manufacturingPhotovoltaic detectorsQuantum dot

The invention provides a perovskite ultraviolet photoelectric detector and a preparation method thereof. The perovskite ultraviolet photoelectric detector includes a quantum dot fluorescent body, a quantum dot fluorescent body CPI substrate completely covering the quantum dot fluorescent body, an ITO conductive glass substrate completely covering the quantum dot fluorescent body CPI substrate, a perovskite light absorption layer array located on the ITO conductive glass substrate and completely surrounded by the ITO conductive glass substrate and a PCBM electron transport layer, the PCBM electron transport layer located among the ITO conductive glass substrate, the perovskite light absorption layer array and a BCP buffer layer, the BCP buffer layer completely covering the PCBM electron transport layer, and an Au electrode located on the BCP buffer layer. A perovskite photodiode includes an ITO conductive glass substrate, a perovskite light absorption layer array, a PCBM electron transport layer, a BCP buffer layer and an Au electrode.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Radiation detector

ActiveUS9046613B2Increase the number of photonsEfficiently incidentMeasurement with scintillation detectorsMaterial analysis by optical meansPhotovoltaic detectorsPhotodetector

A radiation detector for neutrons and gamma-rays includes a conversion screen comprising a mixture of a neutron absorbing material, e.g., containing 6Li, and a phosphorescent material, e.g., ZnS(Ag) and a wavelength-shifting light-guide arranged to receive photons emitted from the phosphorescent material and generate wavelength-shifted photons therefrom. The wavelength-shifting light-guide is doped so as to form a gamma-ray scintillator material operable to generate scintillation photons in response to a gamma-ray detection event therein. A photodetector is optically coupled to the wavelength-shifting light-guide and arranged to detect the wavelength-shifted photons and the scintillation photons. Signals from the photodetector are processed to distinguish neutron detection events from gamma-ray detection events.

Owner:SYMETRICA

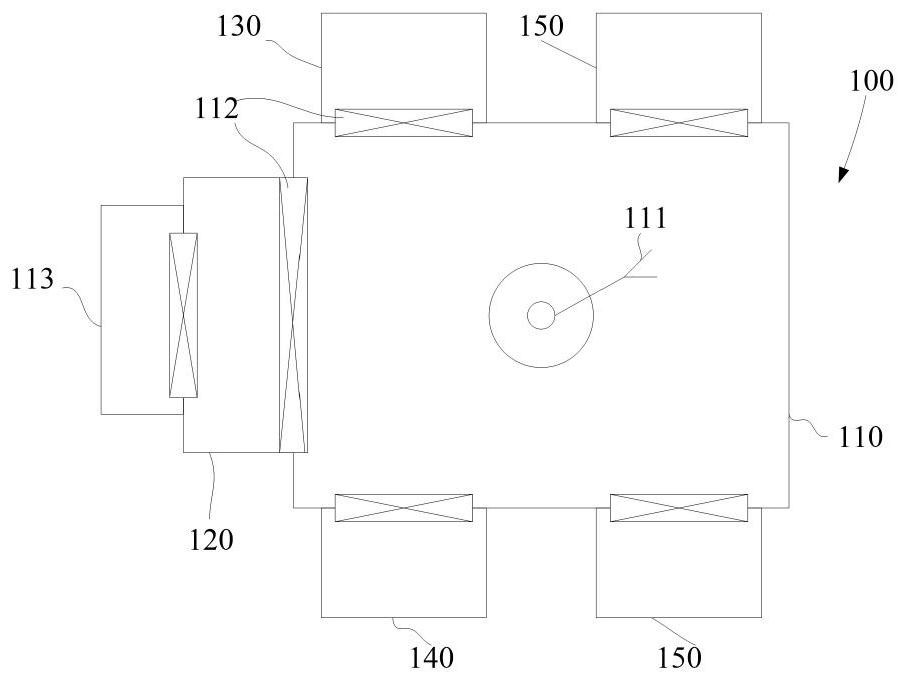

Improved structure of scintillation detector in neutron activation environment

InactiveCN107505647AImprove detection efficiencyHigh resolutionX-ray spectral distribution measurementPhoton yieldHigh energy

The invention discloses an improved structure of a scintillation detector in a neutron activation environment, wherein the improved structure of the scintillation detector is suitable for high-energy gamma-ray measurement. According to the principle of the detector, the energy of a gamma-ray generated by neutron activation is generally 1 to10 MeV; after the ray enters a crystal (5), the electron-pair effect and Compton reaction are produced to generate photoelectrons; high-energy electrons and photons are easy to escape out of a scintillator; the escaped photons are reflected back into the crystal (5) through a reflecting layer (3); a magnetic field provided by a solenoid (2) binds the escaped high-energy electrons back to the crystal (5) by the action of the Lorentz force, and energy is deposited in the crystal; and the photon yield is increased. The improved scintillation detector has the advantages of high measured energy spectrum resolution and high detection efficiency, and has a high practical value in high-precision nuclear spectroscopy measurement such as neutron activation elemental analysis.

Owner:JILIN UNIV

Self-supporting film with microstructured surface and method of making the same

ActiveCN106190101BIncrease the number of photonsHigh quantum yieldNanoopticsLuminescent compositionsQuantum yieldQuantum dot

The invention provides a self-supporting film provided with a microstructure surface and preparation method thereof in the technical field of fluorescence quantum solutions. Firstly, a fluorescence quantum solution and a PVA solution are respectively prepared, then the fluorescence quantum solution is added to the PVA solution for even mixing, and a fluorescence quantum / PVA mixed solution is obtained; then, the fluorescence quantum / PVA mixed solution is added to a mold provided with a microstructure at the bottom, finally heat curing is performed to prepare the self-supporting film provided with the microstructure surface. By arranging the microstructure on the surface of the fluorescent quantum dot self-supporting film, the solid-state fluorescence quantum yield and the corresponding light conversion efficiency are improved. The self-supporting film can be widely applied in lots of fields of photoelectric devices, biological science and the like.

Owner:SHANGHAI JIAOTONG UNIV

Organic electroluminescence element

ActiveUS8569750B2Convenient lightingIncrease the number of photonsDischarge tube luminescnet screensLamp detailsExtinctionRefractive index

Owner:SAMSUNG DISPLAY CO LTD

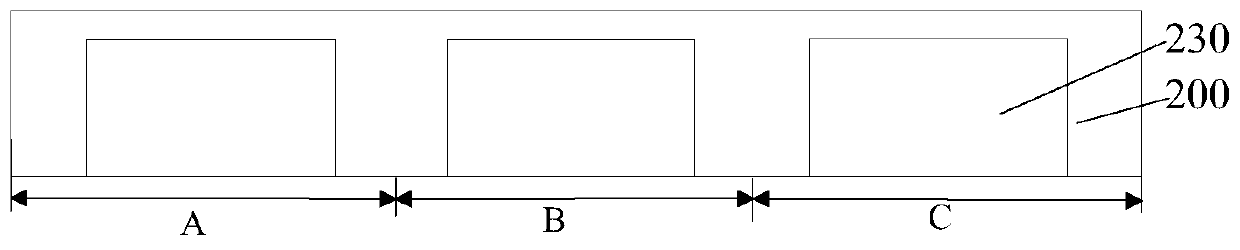

full color oled display

ActiveCN102856350BImprove performanceImprove yield rateSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceGreen-light

The invention relates to a full-color organic light emitting diode (OLED) display which comprises a color conversion substrate, an OLED luminous device and a driving unit for driving the OLED luminous device to illuminate, and is characterized in that a green color conversion film layer covers a green light filter film layer; the OLED luminous device is arranged on a red light filter film layer, the green light filter film layer, a blue light filter film layer, a black matrix grid film layer and color conversion film layers; under the condition of power on, the OLED luminous device can produce electroluminescence; and a luminous spectrum of electroluminescence comprises at least two different types of blue luminous components with CIE color coordinate Y values less than 0.55 and at least one red luminous component with a CIE color coordinate X value more than 0.64. The full-color OLED display has the advantages of high precision, high yield, large size and the like and is favorable for improving the total manufacturing cost performance.

Owner:JIANGSU SUNERA TECH CO LTD

Semiconductor epitaxial structure and application thereof

PendingCN113808980AQuality improvementImprove doping efficiencySemiconductor/solid-state device manufacturingConveyor partsHole injection layerGallium nitride

The invention provides a semiconductor epitaxial structure and application thereof. The structure comprises: a substrate. a first semiconductor layer arranged on the substrate; an active layer arranged on the first semiconductor layer; a second semiconductor layer arranged on the active layer; and a hole injection layer arranged on the second semiconductor layer, wherein the hole injection layer comprises a non-or low-doped gallium nitride layer and / or a doped gallium nitride layer. According to the semiconductor epitaxial structure provided by the invention, the quality of the semiconductor epitaxial structure can be improved.

Owner:SHENZHEN JING XIANG TECH CO LTD +2

Large-size full-color OLED (Organic Light-Emitting Diode) display

ActiveCN102916035BDoes not affect manufacturing process technologyIncrease contrastSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceComputer module

The invention relates to a large-size full-color OLED (Organic Light-Emitting Diode) display, which comprises a complete color converting base plate and a display module. The large-size full-color OLED display is characterized in that a green color converting film is covered on a green filter plate film; the display module is formed by assembling a plurality of display units; each display unit comprises a transparent base plate, a plurality of OLED luminescent devices and a control loop for driving the OLED luminescent devices to radiate light; the transparent base plates are seamlessly adhered onto a red filter plate film, a green filter plate film, a blue filter plate film, a black matrix grid film and a green color converting film on the color converting base plate through colloidal packing material; and each OLED luminescent device in the display unit has a filter plate film on the color converting base plate corresponding to the OLED luminescent device independently. The large-size full-color OLED display has the advantages of being good in visual effect, high in yield and the like, is capable of being convenient to realize size dimension, and is beneficial for improving the performance price ratio for manufacturing the display.

Owner:JIANGSU SUNERA TECH CO LTD

Photon counting type communication receiving device with photon number resolution

ActiveCN104579498BReduce bit error rateIncrease the number of photonsElectromagnetic receiversPhotomultiplierPhoton counter

A photon counting type communication receiving device with a distinguishable photon number, which is composed of a receiving lens, an interference filter, a photomultiplier tube, an amplifier, a comparator, a photon counter, a demodulation decoder and a host computer in sequence. The described comparator is a multi-level comparator, which is composed of more than 2 micro-power consumption comparison chips in parallel, and each micro-power consumption comparison chip is respectively set with a comparison threshold value, and the described photon counter is a multi-photon counter. The traditional single-photon counting type communication device has the advantages of high response sensitivity to weak light, and can also significantly reduce the bit error rate and ensure the reliability of communication.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com