Full-color organic light emitting diode (OLED) display

A display and red technology, which is applied in the manufacture of electric solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of low efficiency, low life, backwardness, backward efficiency or lifespan, etc., achieve high precision, improve manufacturing cost performance, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

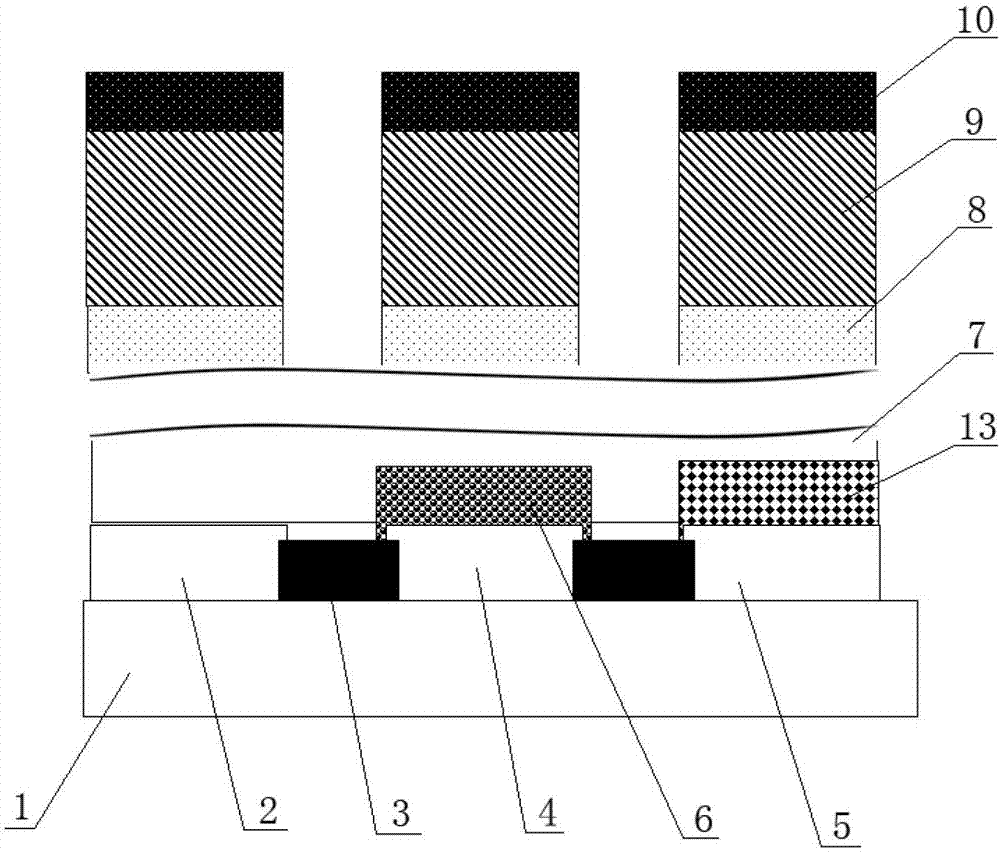

[0097] figure 2 Shown is the first structure of the full-color OLED display in the color conversion mode of the present invention, which includes a color conversion substrate, an OLED light-emitting device and a driving unit for driving the OLED light-emitting device to emit light; the color conversion substrate includes a transparent substrate 1, One surface of the transparent substrate 1 is covered with a red filter film layer 5, a green filter film layer 4 and a blue filter film layer 2, and the filter film layers of various colors are provided with Black matrix grid film layer 3; its innovative point is: the green filter film layer 4, the red filter film layer 5 and the black matrix grid film layer 3 between them are fully covered with the same kind of A green color conversion film layer 6 made of a green color conversion material; the OLED light-emitting device is arranged on the red, green, and blue filter film layers, the black matrix grid film layer 3 and the color co...

Embodiment 2

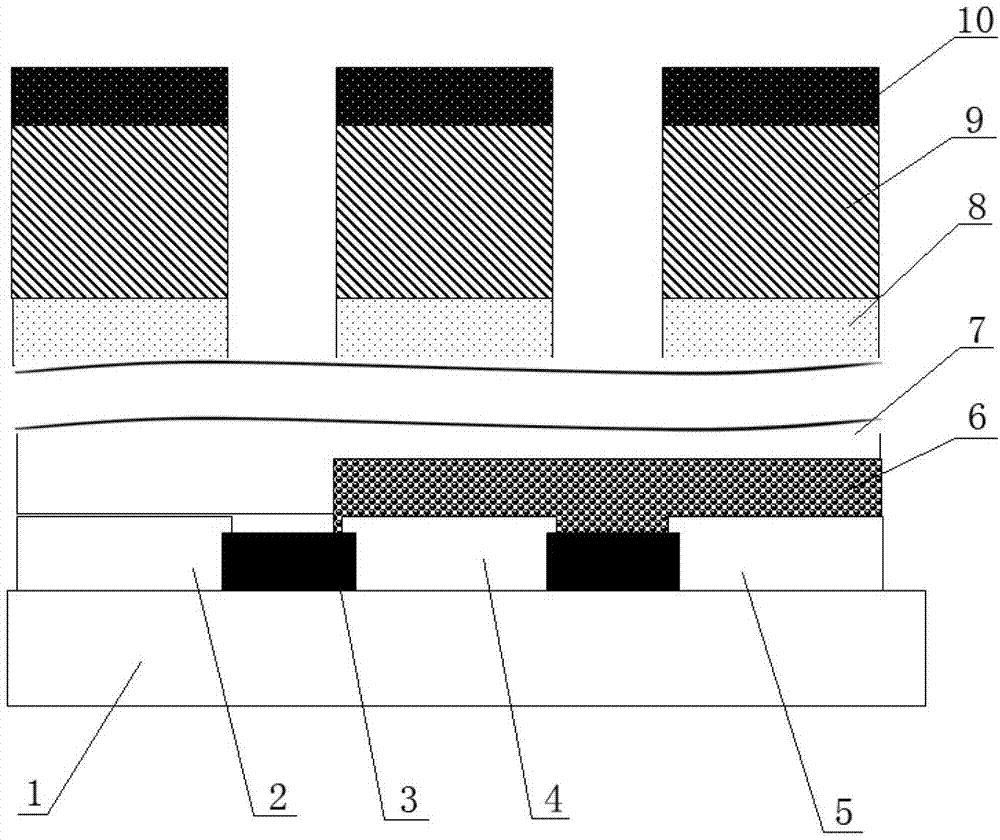

[0150] image 3 Shown is the second structural form of the full-color OLED display of the present invention, which is the same as figure 2 The structural form shown in is different in that the color conversion film layer constituting the full-color OLED display does not continuously cover the red filter film layer 5, the green filter film layer 4 and the black matrix network between them grid film layer 3, but relatively independently covering the red filter film layer 5 and the green filter film layer 4, this composition feature is only the selectivity of color change film process processing is different, for The performance of full-color OLED displays is not affected.

Embodiment 3

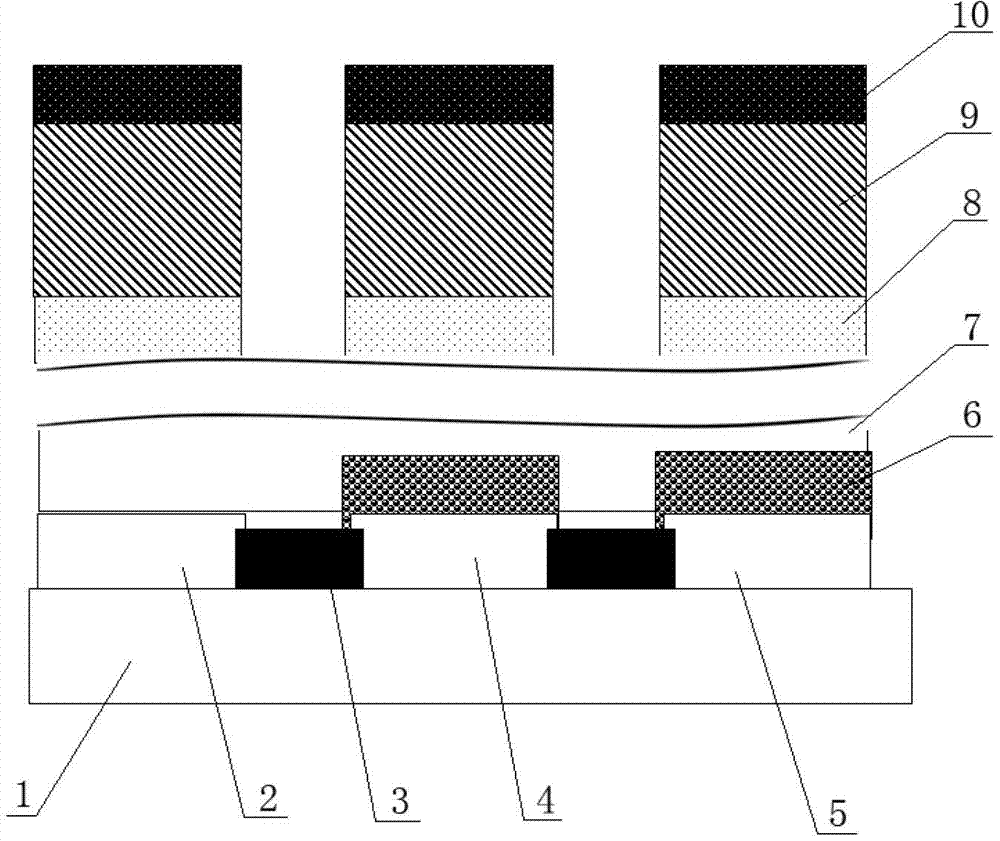

[0152] Figure 5 Shown is the third structural form of the full-color OLED display of the present invention, which is the same as figure 2 The structural form shown in is different in that the color conversion film layer constituting the full-color OLED display only covers the green filter film. The characteristic of this composition is that the photoluminescence of the green color conversion material only serves The green pixel, as for the red pixel, all of its luminescence comes from the electroluminescence of the OLED light emitting device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com