Top-light-emission full-color organic light emitting diode (OLED) display

A top-emitting and display technology, applied in the field of display manufacturing, can solve the problems of low display yield and limit the market promotion and application of OLED full-color display screens, and achieve the effects of high yield, high precision, and improved manufacturing cost-effectiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

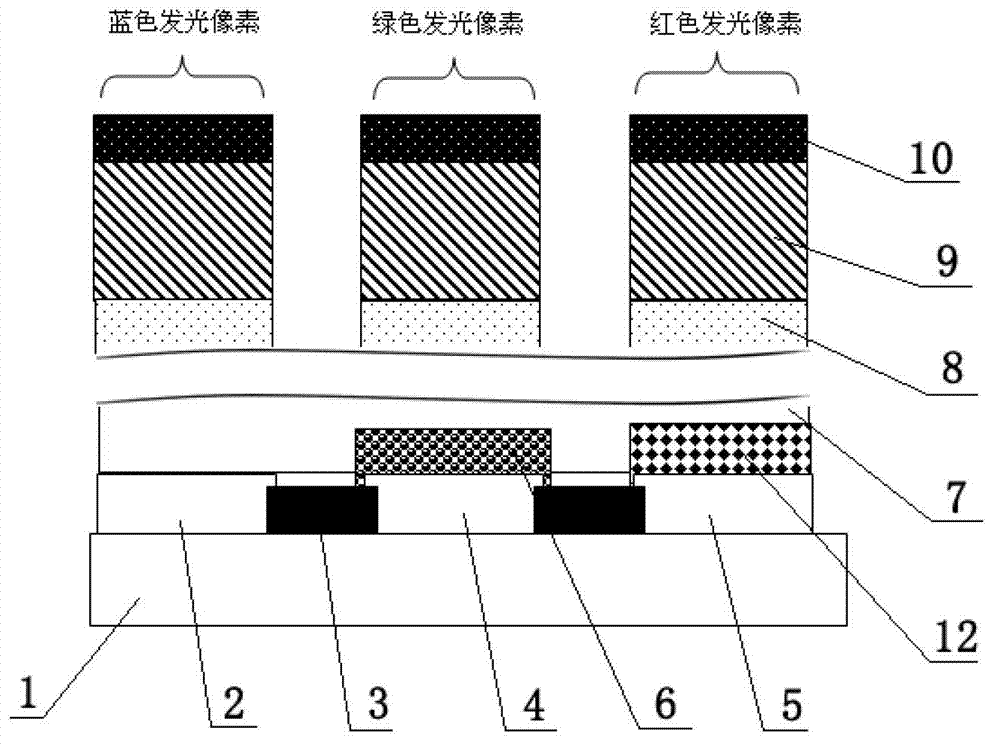

[0104] figure 2 Shown is the first structure of the top-emitting full-color OLED display of the present invention, which is mainly composed of a filter substrate, a color conversion film layer, an OLED light-emitting device, and a driving unit 11 for driving the OLED light-emitting device to emit light; The filter substrate is mainly composed of a transparent substrate 1, a blue filter film layer 2, a black matrix grid film layer 3, a green filter film layer 4 and a red filter film layer 5, and the blue filter film layer Layer 2, green filter film layer 4 and red filter film layer 5 are covered on the transparent substrate 1; the OLED light-emitting device is made on the drive unit 11, and the OLED light-emitting device is composed of a light-transmitting electrode layer 8, an organic The light-emitting functional material film layer combination 9 and the reflective electrode layer 10 are composed. The light-transmitting electrode layer 8 is adjacent to the above-mentioned co...

Embodiment 2

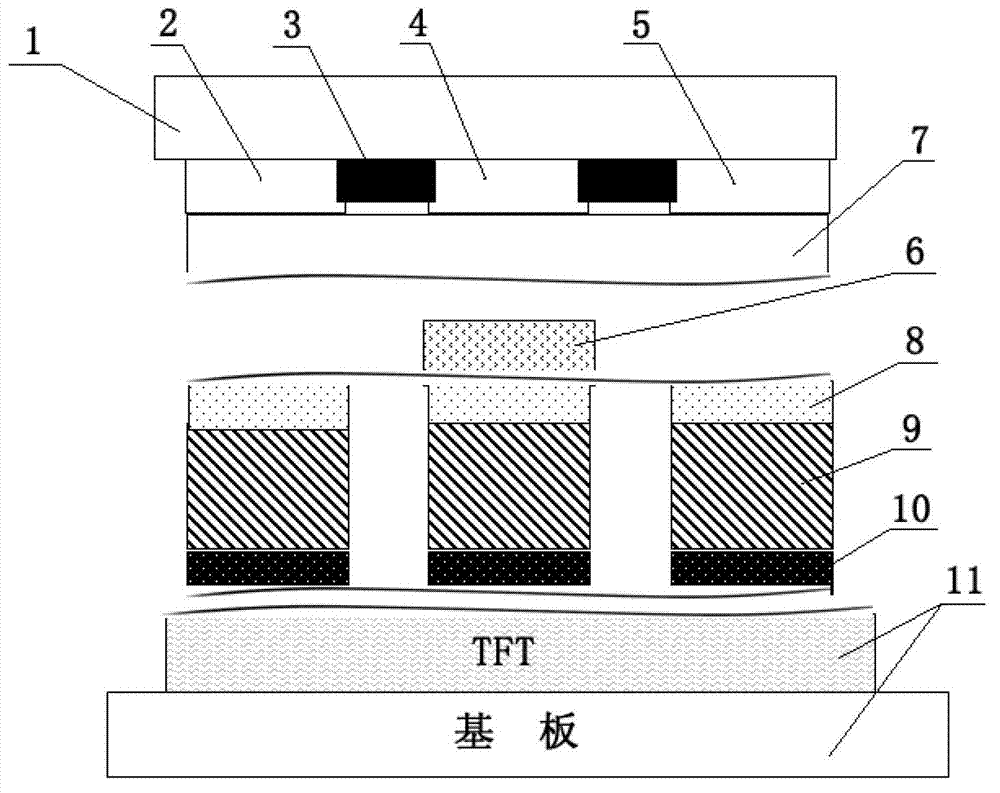

[0153] image 3 Shown is the second structural form of the full-color OLED display of the present invention, which is the same as figure 2 The structural form shown in is different in that the color conversion film layer constituting the full-color OLED display continuously covers the top electrode of the OLED light-emitting device of the red pixel, the top electrode of the OLED light-emitting device of the green pixel, and the space between them Above, the photoluminescence of the green color conversion material serves both green and red pixels.

Embodiment 3

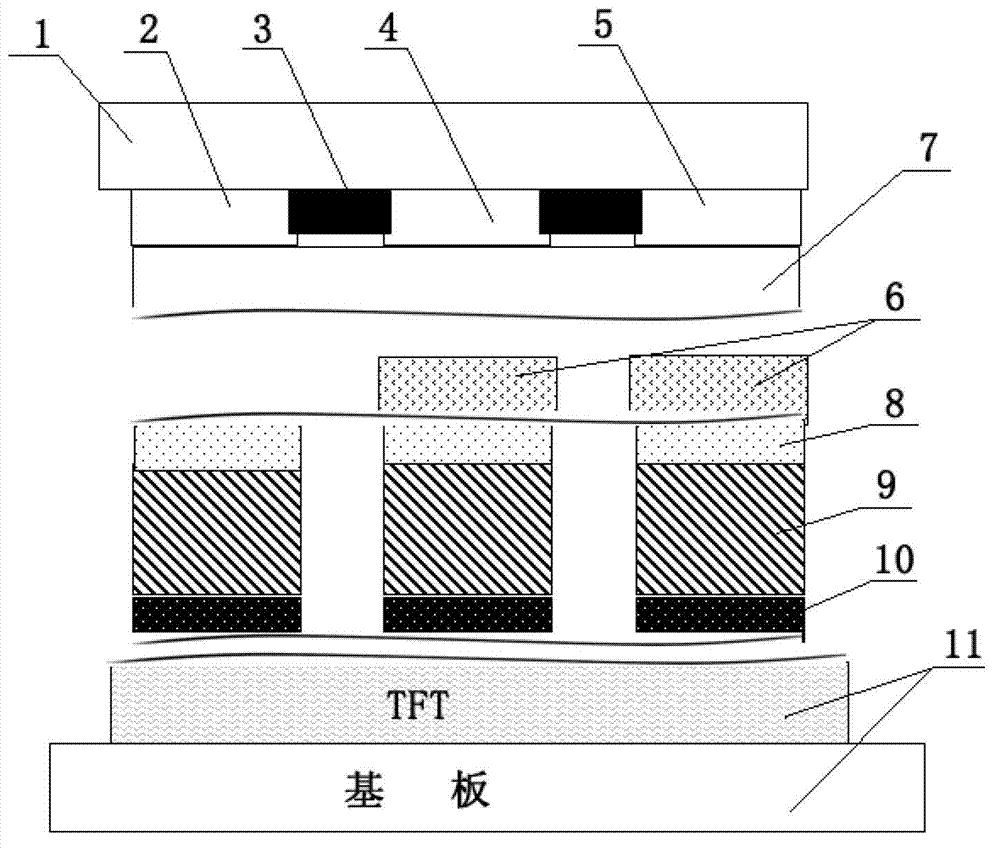

[0155] Figure 4 Shown is the third structural form of the full-color OLED display of the present invention, which is the same as figure 2 The structural form shown in is different in that the color conversion film layer constituting the full-color OLED display not only covers the top electrode of the green light-emitting pixel OLED light-emitting device, but also covers the top electrode of the red OLED light-emitting device , the photoluminescence of the green color conversion material serves both green and red pixels. Compared with Example 2, this compositional feature is only a difference in the selectivity of the process of the color change film layer, and does not affect the efficiency performance of the full-color OLED display.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com