Organic electroluminescence element

A technology for electroluminescent elements and organic light-emitting layers, which can be applied to electroluminescent light sources, electrical components, organic semiconductor devices, etc., and can solve the problems of scattered reflection and refraction angles, and unclear optical design guidelines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

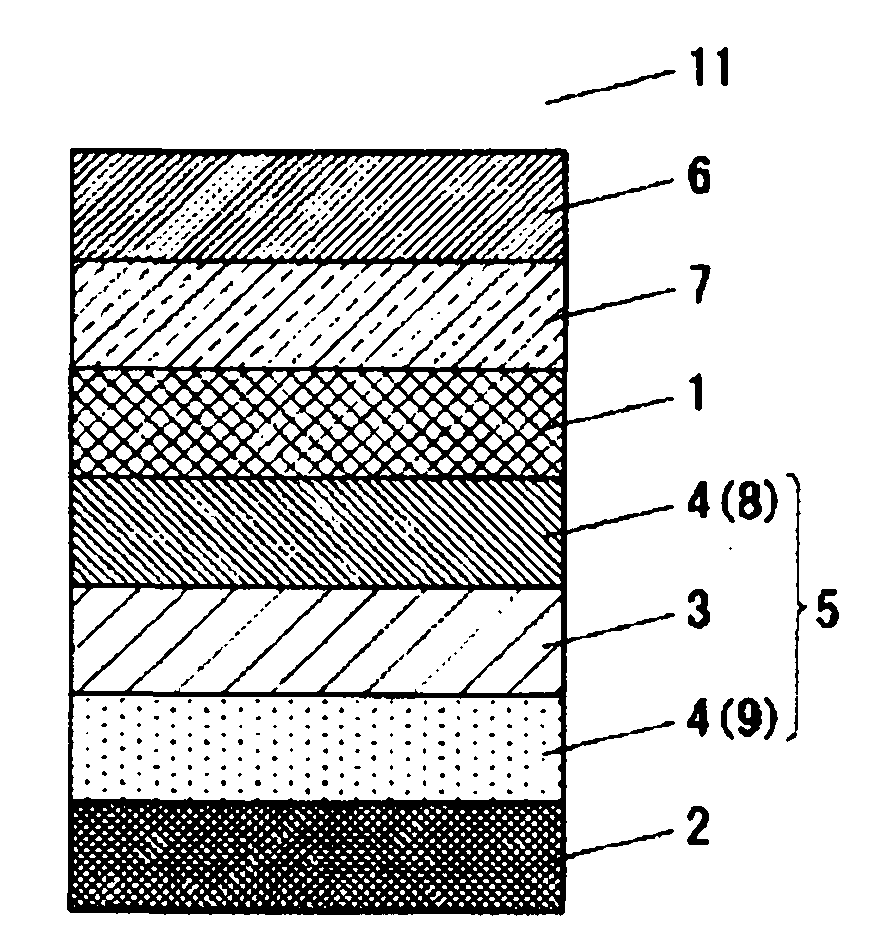

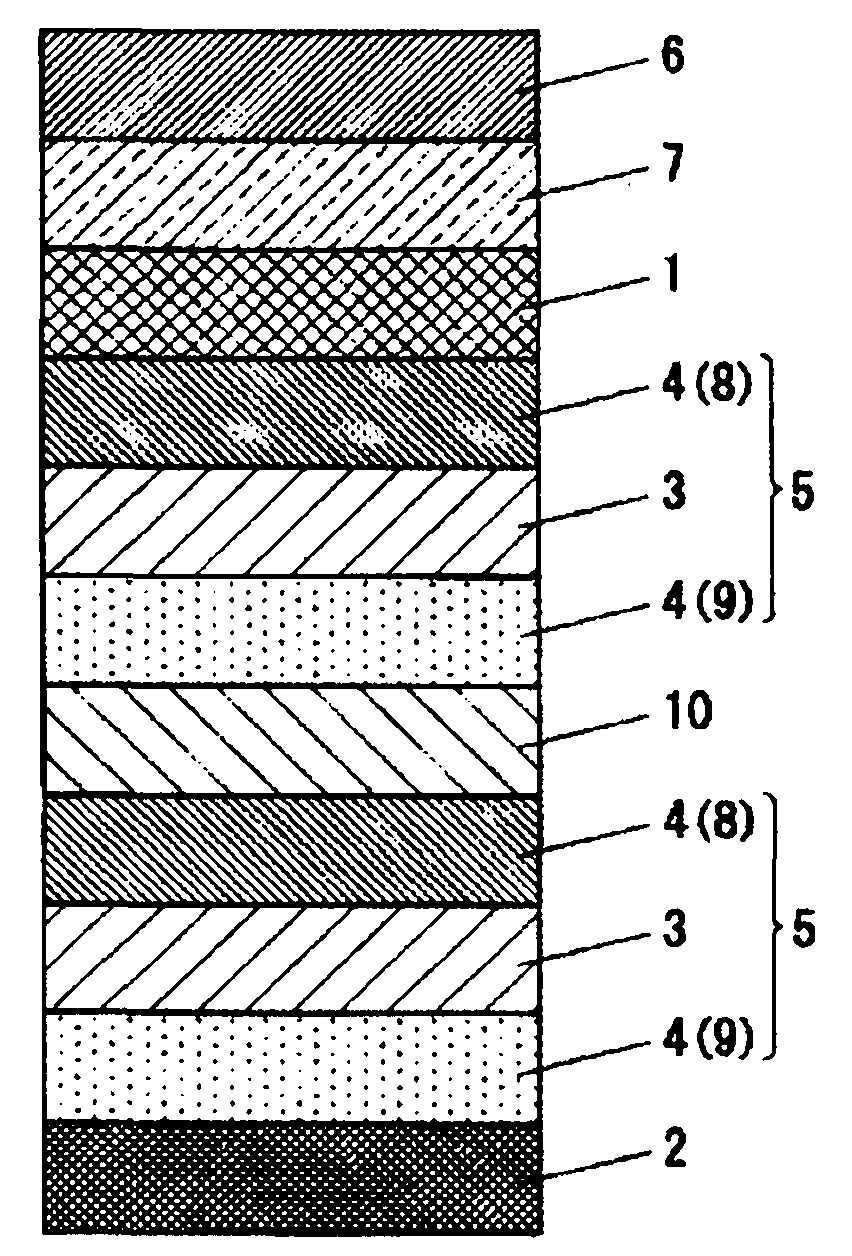

Method used

Image

Examples

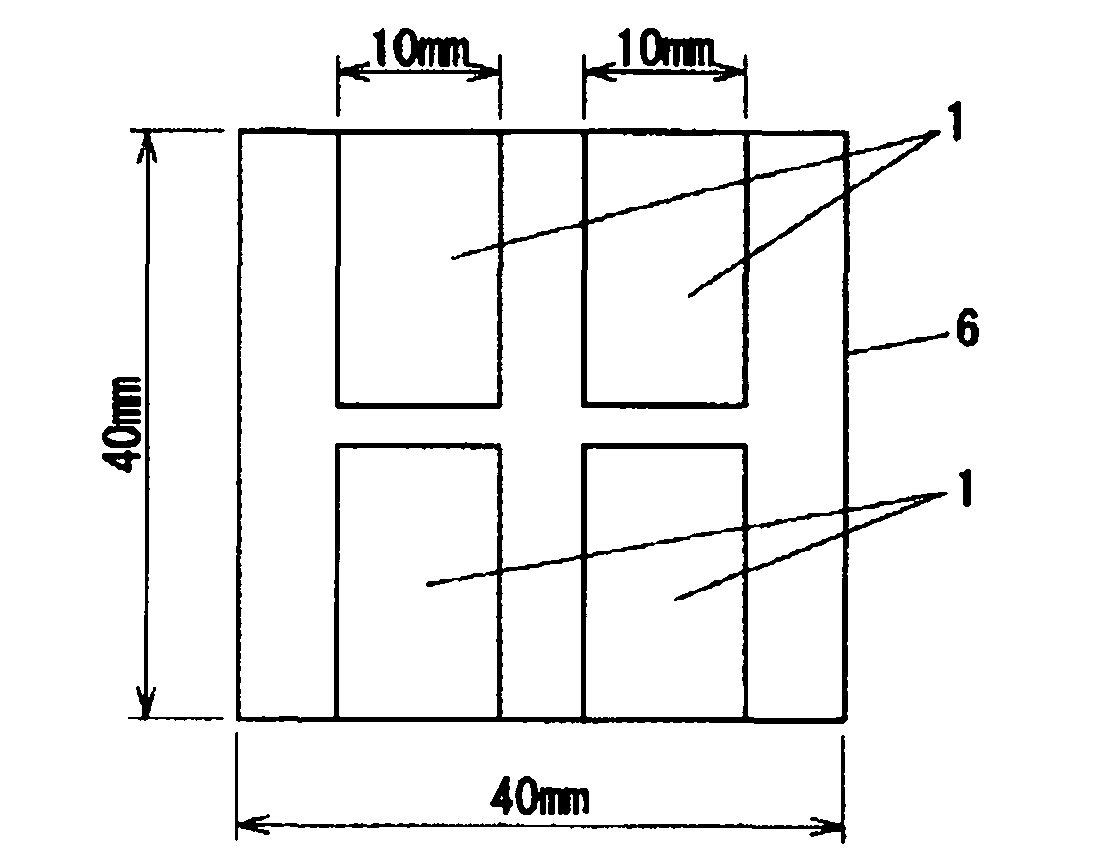

Embodiment 1

[0102] The light-transmitting substrate 6 provided with the light-scattering layer 7 was produced as follows. First, add 803.5 g of isopropyl alcohol to 86.8 g of tetraethoxysilane, then add 34.7 g of γ-methacryloxypropyl trimethoxysilane and 75 g of 0.1N-nitric acid, and mix well with a mixer to obtain solution. The obtained solution was stirred in a 40 degreeC thermostat for 2 hours, and the 5 mass % solution of the silicone resin with a weight average molecular weight of 1050 was obtained as a binder formation material.

[0103] To this silicone resin solution, methyl silicone particles (average particle diameter 2 μm, manufactured by GE TOSHIBA SILICONE CO., LTD, "Tospearl 120") were added to obtain a solid mixture of methyl silicone particles / silicone resin (in terms of polycondensation compound) The component mass standard was set to 80 / 20, and the mixture was dispersed with a homogenizer to obtain a methyl silicone particle-dispersed silicone resin solution. Here, "co...

Embodiment 2

[0115] An organic electroluminescent element was obtained under the same conditions as in Example 1 except that the thickness of the electron transport layer 9 was set to 235 nm.

Embodiment 3

[0117] An organic electroluminescent element was obtained under the same conditions as in Example 1 except that the thickness of the electron transport layer 9 was set to 350 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com