Full-color OLED (Organic Light Emitting Diode) display made by adopting multi-component OLED luminescent device technology and filtering technology

A technology of light-emitting device and filter technology, applied in semiconductor/solid-state device manufacturing, electric solid-state device, semiconductor device, etc., can solve the problems of service life and efficiency gap, low luminous efficiency, overall performance disadvantage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

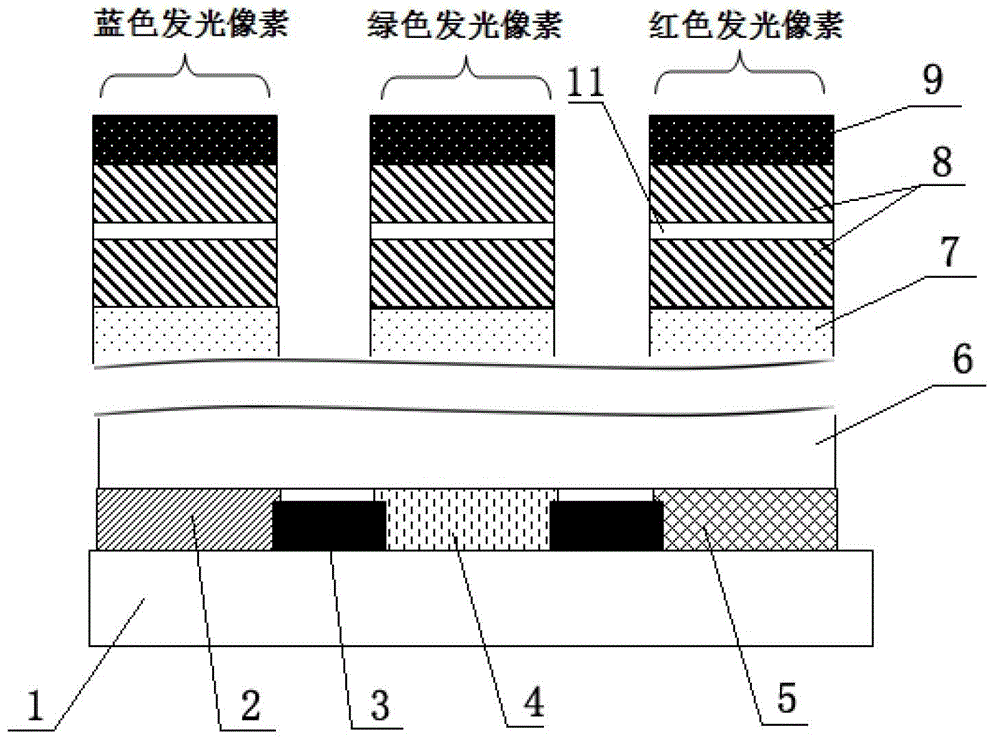

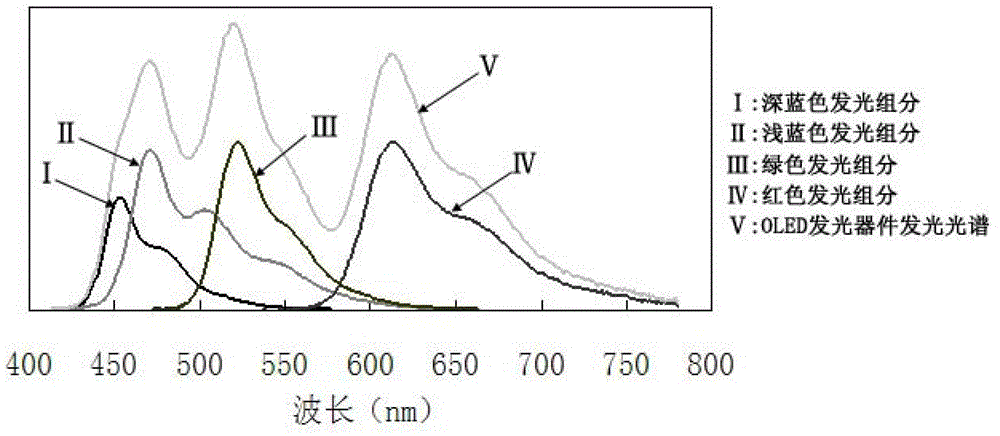

[0058] figure 1Shown is the first structural schematic diagram of a full-color OLED display made of multi-component OLED light-emitting device technology combined with light filtering technology, which is mainly composed of a filter substrate, an OLED light-emitting device and a driving unit for driving the OLED light-emitting device to emit light Composition; the filter substrate includes a transparent substrate 1, a blue filter film layer 2, a black matrix grid film layer 3, a green filter film layer 4 and a red filter film layer 5, and a blue filter film layer The film layer 2, the green filter film layer 4 and the red filter film layer 5 are covered on the transparent substrate 1, and the black matrix grid film layer 3 is arranged between the three color filter film layers; Each filter film layer has a corresponding OLED light-emitting device, and all OLED light-emitting devices have the same structure. A blue luminescent component with a CIE color coordinate Y value of l...

Embodiment 2

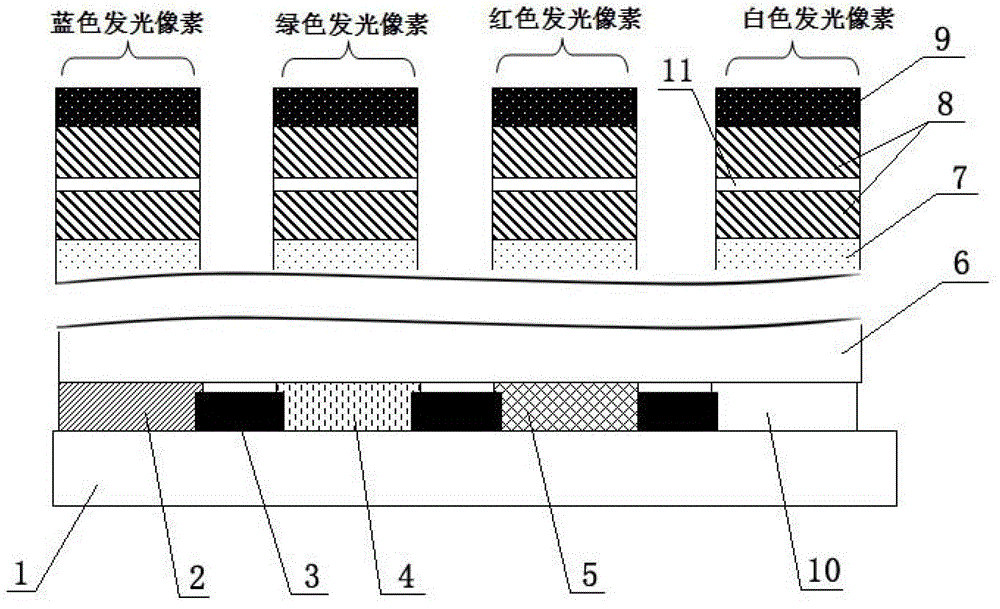

[0099] figure 2 Shown is a second structural schematic diagram of a full-color OLED display produced by combining multi-component OLED light-emitting device technology with light filtering technology. In addition to the layer 5, the green filter film layer 4 and the blue filter film layer 2, it also includes a white pixel area 10 that can emit white light, and the white pixel area 10 is connected with the filter film layers of other colors. A black matrix grid film layer 3 is also arranged between them, and the white pixel area 10 also has a corresponding OLED light-emitting device.

[0100] The red filter film layer 5, the green filter film layer 4, the blue filter film layer 2 and the white pixel area 10 are in accordance with figure 2 In addition to the bar-shaped arrangement shown, it can also be arranged in a stacked square shape ( Figure 5 As shown), for full-color OLED displays, this change in arrangement is only a difference in the process selectivity of the color...

manufacture Embodiment 1

[0102] follow below figure 1The shown structure specifically describes the manufacturing process of the full-color OLED display of the present invention.

[0103] (1) In the form of entrusted processing, obtained from Chunghwa Picture Tubes Co., Ltd. (headquartered in Taiwan) including red filter film layer 5, green filter film layer 4, blue filter film layer 2 and black The filter substrate of the matrix grid film layer 3 has a standard size of 2.4 inches QVGA, in which the thickness of the red filter film layer 5 is 3 microns, the thickness of the green filter film layer 4 is 3 microns, and the blue film layer 5 has a thickness of 3 microns. The thickness of the filter film layer 2 is 3 microns, and the transmittances of the above-mentioned different color filter film layers are as follows: Figure 4 shown.

[0104] (2) On the above-mentioned optical filter substrate, a photolithography process is used to further smear and manufacture a planarized film layer 6 with a film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com