Image sensor and formation method

An image sensor and graphic technology, applied in the direction of radiation control devices, etc., can solve the problems of poor image sensor performance and low photosensitivity, and achieve the effects of improving photoelectric conversion efficiency, sensitivity, and photosensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] As mentioned in the background, prior art image sensors perform poorly.

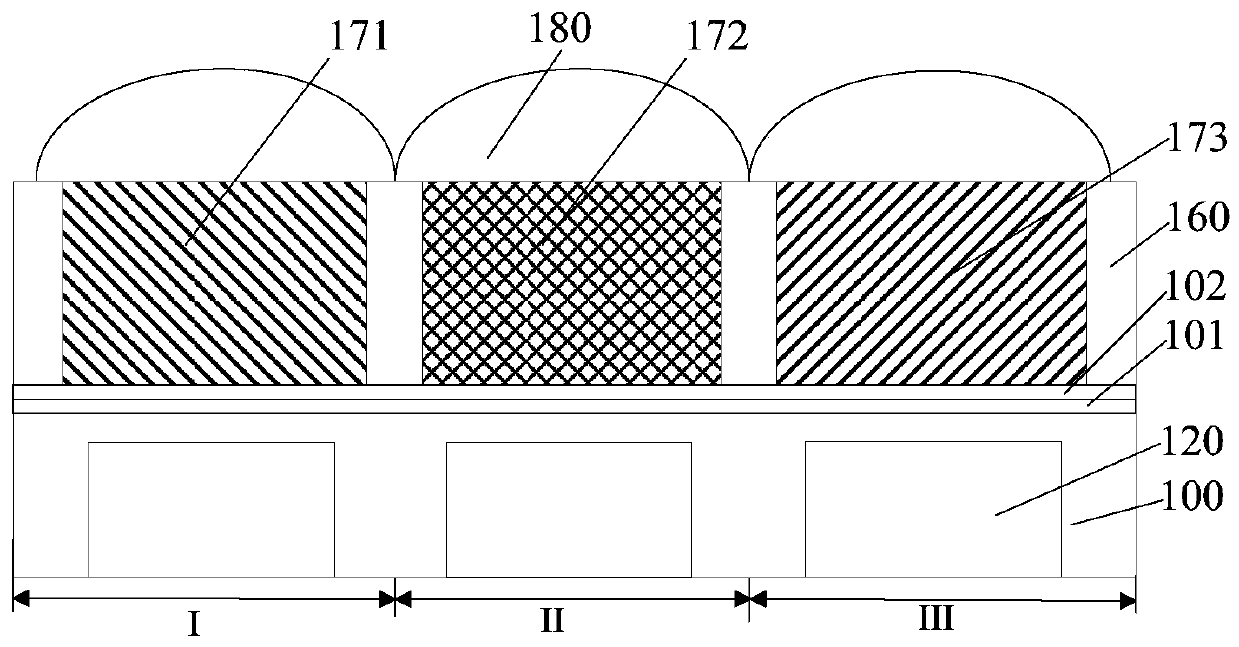

[0026] figure 1 It is a schematic diagram of the cross-sectional structure of an image sensor.

[0027] An image sensor, reference figure 1 , comprising: a semiconductor substrate 100 having opposite first and second surfaces; a photosensitive structure 120 located in the semiconductor substrate 100, the first surface of the semiconductor substrate 100 exposing the photosensitive structure 120 The anti-reflection coating 101 positioned on the second surface of the semiconductor substrate 100; the anti-reflection layer 102 positioned on the surface of the anti-reflection coating 101; Filter layer and lens layer 180.

[0028] figure 1 shows three pixel units of the image sensor, including green pixel unit I, blue pixel unit II and red pixel unit III.

[0029] The filter layer located in the green pixel unit I is the G filter layer 171; the filter layer located in the blue pixel unit II is the B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com