Self-supporting film with microstructured surface and method of making the same

A self-supporting, microstructured technology, applied in chemical instruments and methods, nanotechnology, nano-optics, etc., can solve the problem of large loss of fluorescence quantum yield, achieve improved quantum yield, improved conversion efficiency, and improved light absorption rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment relates to a method for preparing a carbon quantum dot self-supporting film with a microstructure surface, comprising the following steps:

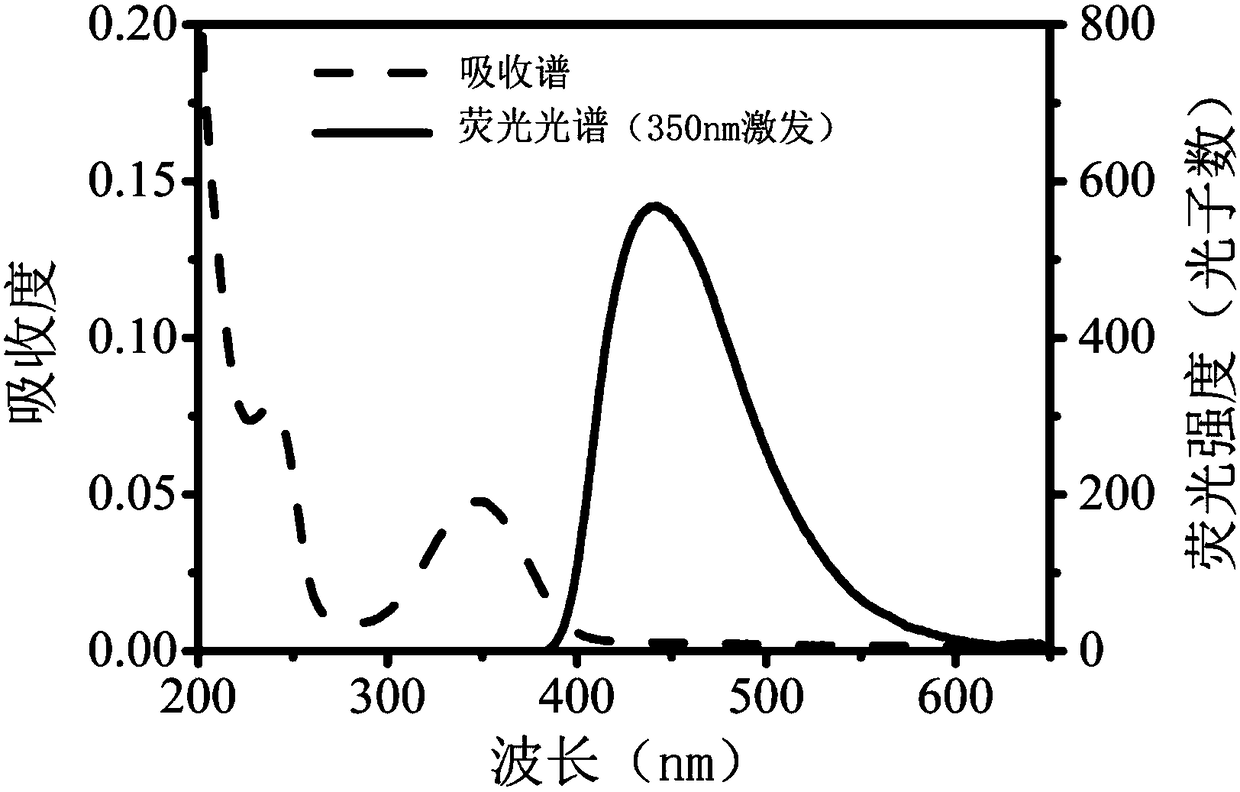

[0027] S 1 , Synthesis of carbon quantum dots by hydrothermal method: Take 787mg of citric acid monohydrate, 250uL of ethylenediamine, 500uL of 25wt% ammonia water and add 10mL of deionized water to fully mix them, then place them in a polytetrafluoroethylene reactor, and heat at 200°C for 2 Hours, after the solution is cooled to room temperature, deionized water is added to dilute to obtain an aqueous solution of carbon quantum dots; the mass percentage range of carbon quantum dots in the solution is [0.02wt%, 0.1wt%], and the fluorescence quantum yield is 72.4%;

[0028] S 2 , the configuration PVA mass percentage is the carbon quantum dots / PVA mixed solution of 5wt%, after stirring evenly, add in the mold that is provided with microstructure at the bottom, the liquid level height is 1~3mm, carbon quantum dots / PV...

Embodiment 2

[0042] This embodiment relates to a method for preparing a CdSe / CdS core-shell structure quantum disk self-supporting film with an inverted pyramid microstructure surface, comprising the following steps:

[0043] S 1 , take 480mg of cadmium acetate and 1.18g of oleic acid and stir at 110°C for 90 minutes in a vacuum environment to obtain a mixed solution of cadmium acetate / oleic acid; disperse 72mg of selenium powder in 2mL of octadecene, inject the mixed solution of cadmium acetate / oleic acid , slowly raised the temperature to 240°C, then added 240mg of cadmium acetate, and continued to heat for 15 minutes to react; then cooled to room temperature, then added 10mL of oleic acid, centrifuged to obtain a precipitate, and dispersed the precipitate in n-hexane to obtain a mixture of n-hexane solution;

[0044] S 2 , Synthesis of CdSe / CdS core-shell structure quantum disk: Take 40 μL of n-hexane mixed solution and add 2 mL of chloroform to mix evenly, then add 20 mg of thioaceta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com