Light-emitting diode

A light-emitting diode and chip technology, which is applied in the direction of electrical components, electric solid-state devices, circuits, etc., can solve the problems of light energy loss, reduce the light output efficiency of light-emitting diodes, etc., and achieve the effect of improving light output efficiency and reducing total reflection phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings.

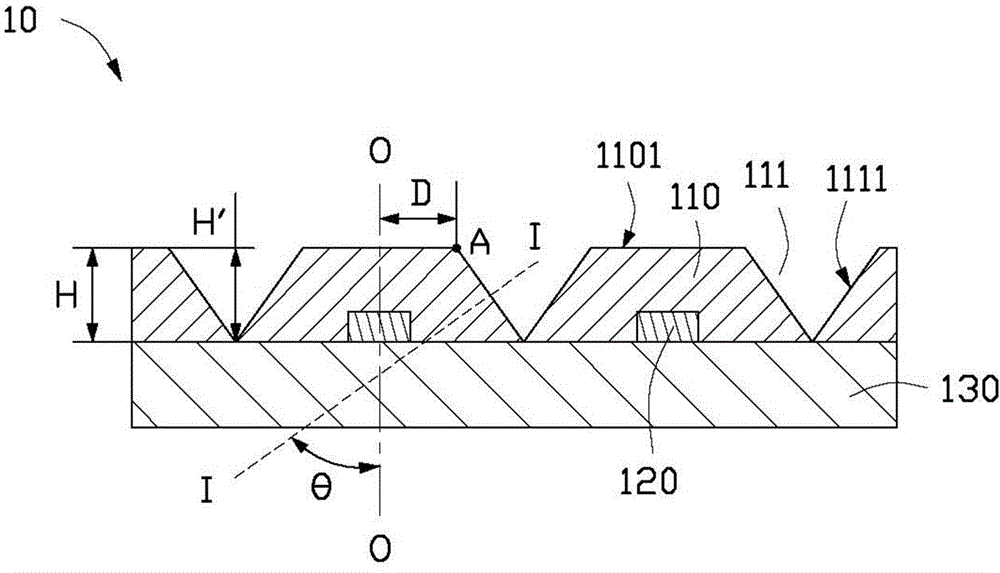

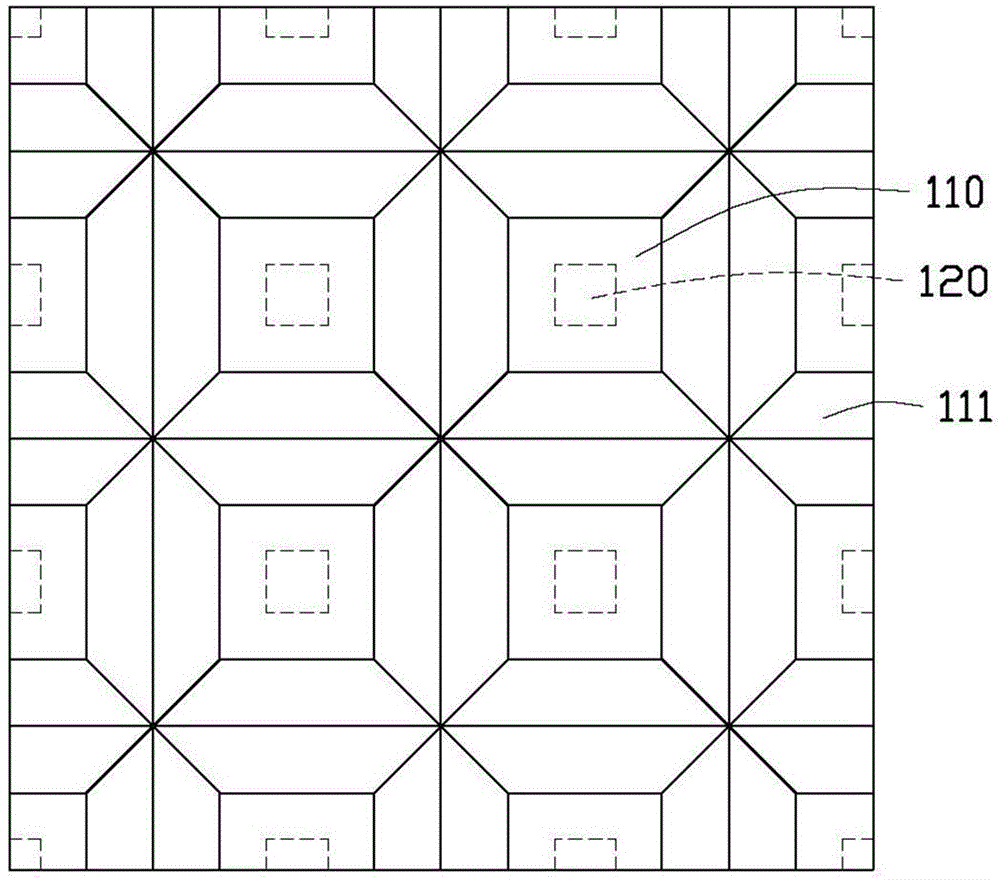

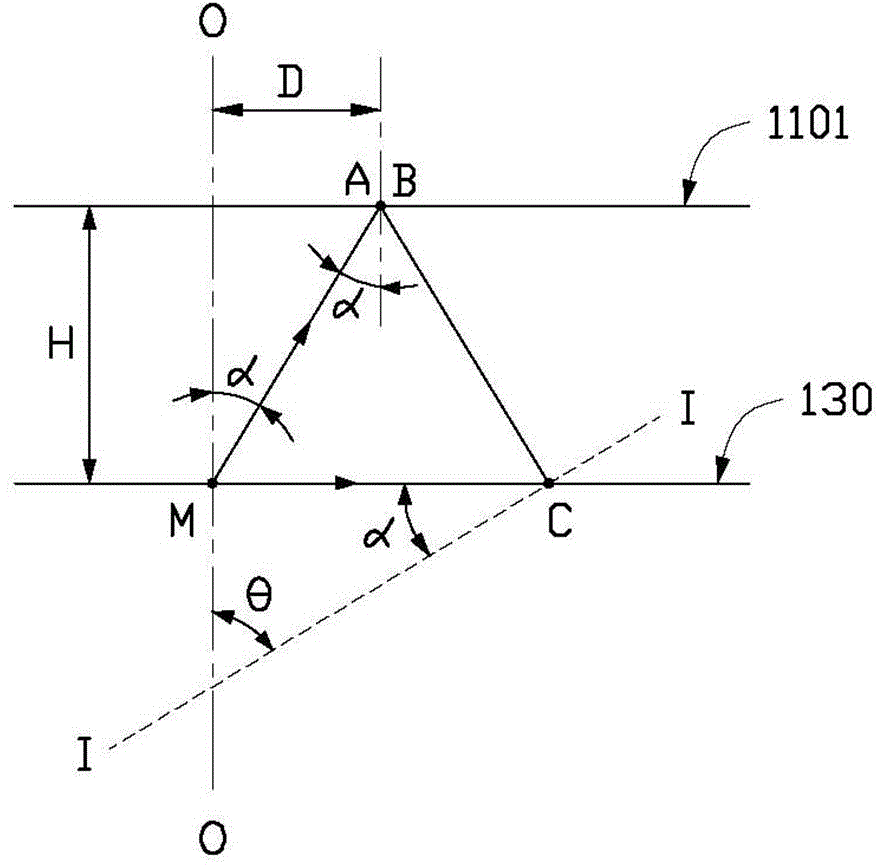

[0016] See figure 1 The light-emitting diode 10 provided by the present invention includes a substrate 130 having a circuit structure, at least one light-emitting diode chip 120 and a packaging material 110. The light emitting diode chip 120 is disposed on the substrate 130 and is electrically connected to the circuit structure of the substrate 130. The electrical connection mode of the circuit structure of the light-emitting diode chip 120 and the substrate 130 can be a wire bonding connection or a flip chip connection. The substrate 130 may be a PCB substrate, a ceramic substrate, a metal substrate, or a flexible substrate. The packaging material 110 covers the light emitting diode chip 120. The refractive index of the packaging material 110 is 1.4-1.5. The packaging material 110 may include a fluorescent substance.

[0017] The packaging material 110 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com