Multicomponent cartridges, dispensing devices for multicomponent cartridges and systems for mixing and spraying flowable components

A multi-component and mixer technology, which is applied to the surface coating liquid device, mixer, spraying device, etc., can solve the problems of cost input, slowness, and high time input, and achieve cheap manufacturing, simple connection, and simple The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

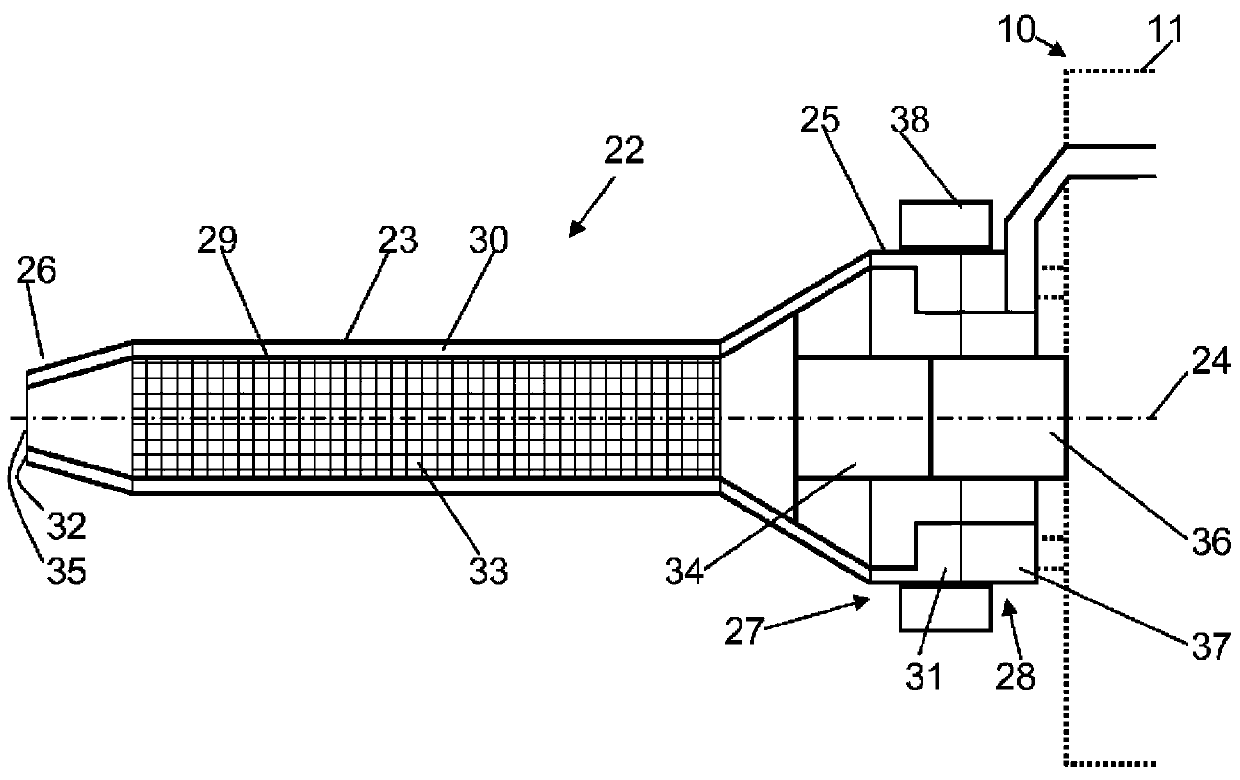

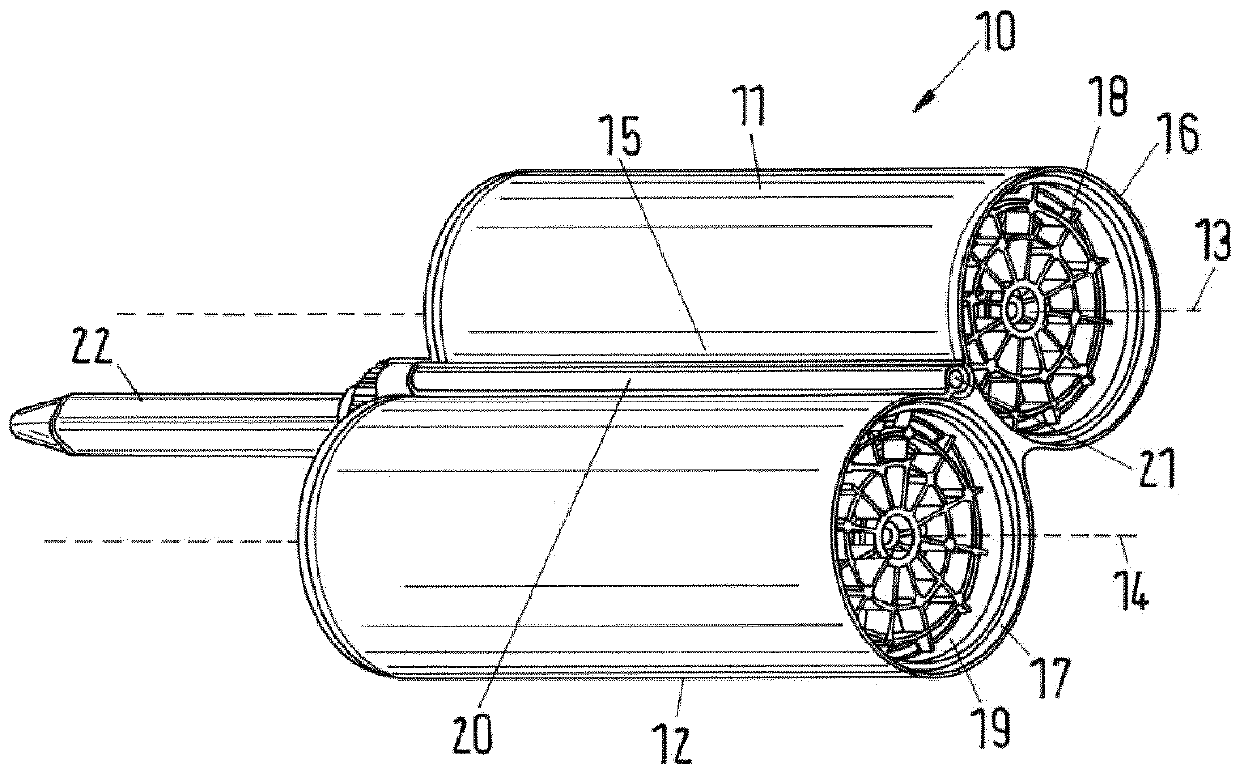

[0037] according to figure 1 , the multi-component cartridge 10 has a first container 11 for receiving a first component and a second container 12 for receiving a second component. The first container 11 and the second container 12 have a cylindrical basic shape with a first cylinder axis 13 and a second cylinder axis 14 . The two containers 11, 12 are arranged axially adjacent to each other. The containers 11, 12 are connected to each other with a minimum spacing from each other. Thus, a groove 15 is created between the two containers, which extends parallel to the two cylinder axes 13 , 14 . The multicomponent cartridge 10 is therefore designed as a so-called side-by-side cartridge. The containers 11, 12 of the multicomponent cartridge 10 have the same diameter. Thus, when dispensing from the containers 11, 12, the mixing ratio of the components is equal to 1:1. However, other diameters (and thus other mixing ratios) are also possible, for example 1:2, 1:4, 1:10 or high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com