Automatic feeding system of foam material

An automatic feeding and material technology, which is applied in the field of automatic feeding system of foam materials, can solve the problems of no savings in labor costs, large consumption of manpower and time, high labor costs, etc., and achieve the effect of efficient mixing, grinding and stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

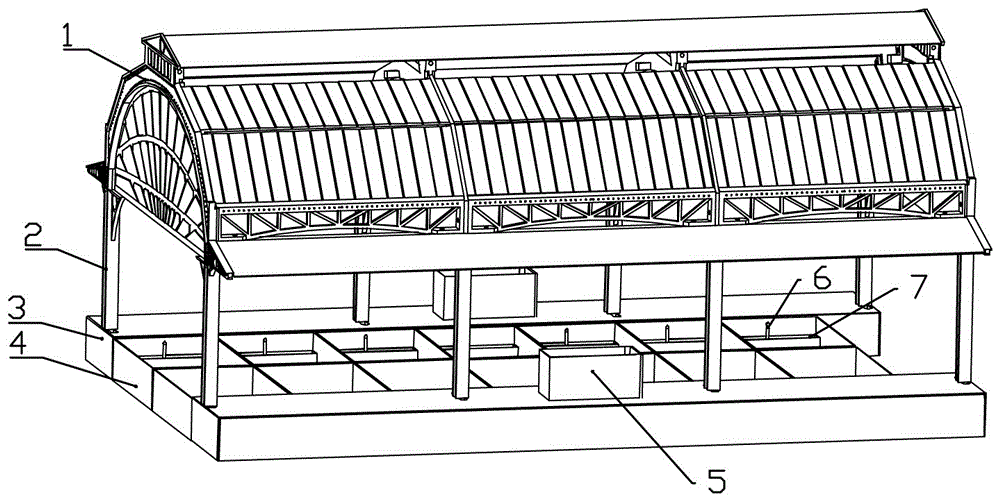

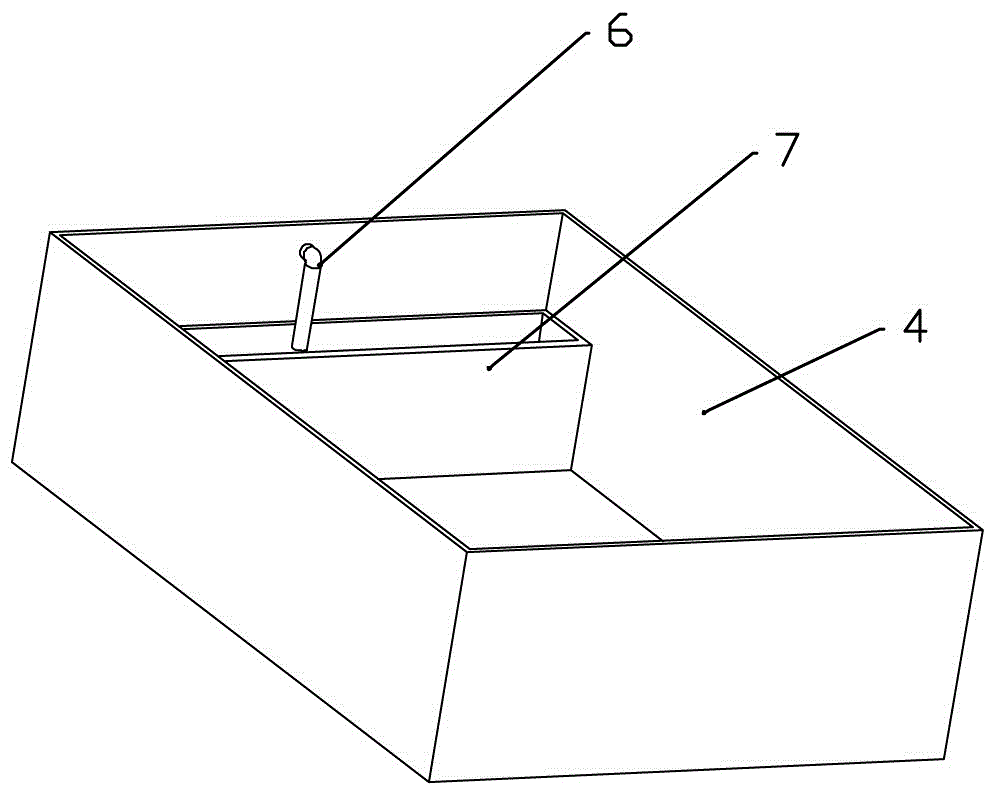

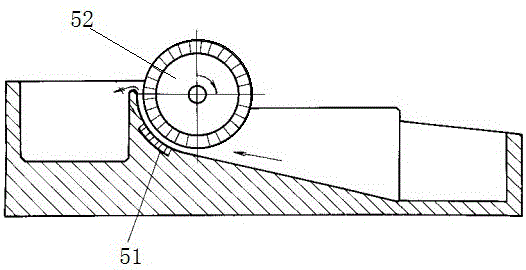

[0012] combined with figure 1 , 2 The automatic feeding system of the foam material shown in 3 includes a shed, and the shed is provided with a shed roof 1 and a supporting shed post 2, wherein a feeding platform 3 is provided in the shed, and a feeding platform lower than the feeding platform 3 is provided. Groove 4, feeding platform 3 are provided with feed processing tank 5, and the bottom of feed processing tank 5 is laid with heating pipe, and the pulping device is installed in feed processing tank 5, and feed processing tank 5 is provided with feed inlet and discharge port, and the outlet The feeding port is communicated with the trough 7 of the feeding trough 4 through the pipeline 6 . The feed processing tank 5 is provided with a water injection pipe 6 and a sewage outlet. The bottom of the feed processing tank 5 is provided with a feeding slope, and a refining device is installed on the top of the feeding slope. The refining device includes a refining knife roller 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com