3d powder turbulence reducer

A distributor and powder delivery technology, which is applied in fire rescue and other fields, can solve the problems of fire extinguishing failure and efficiency reduction of dry powder fire extinguishing system, and achieve the effect of preventing sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

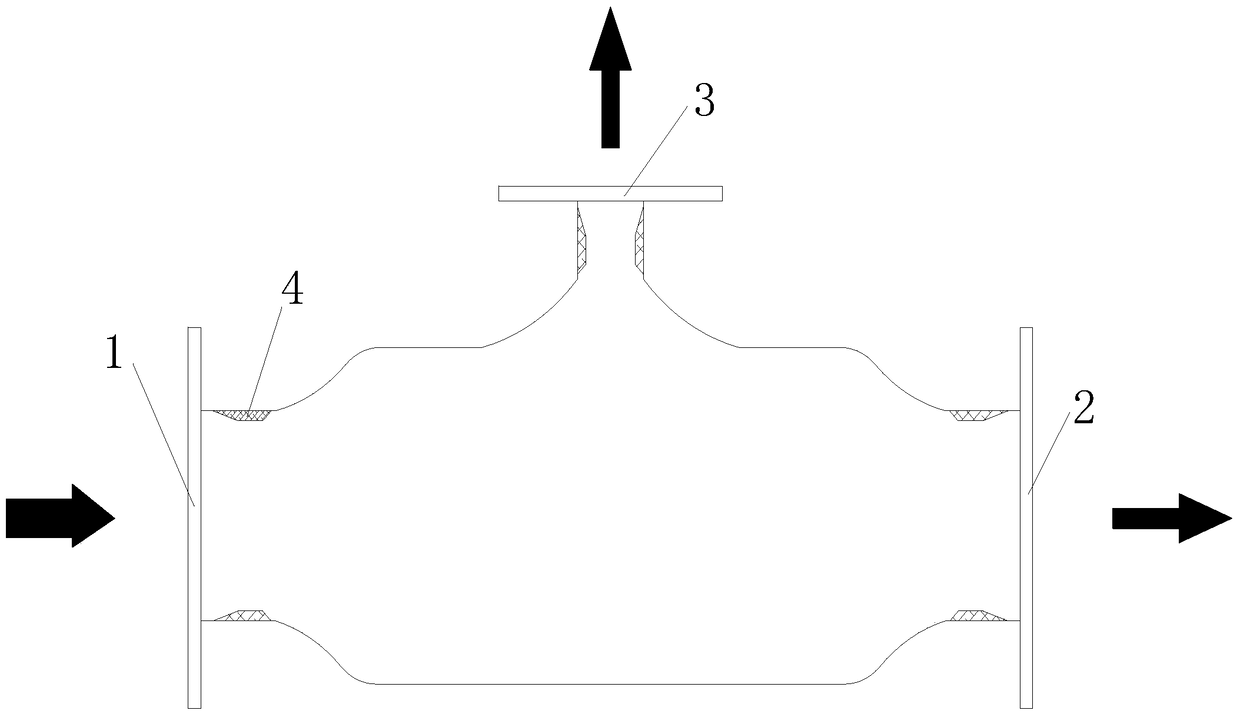

[0011] like figure 1 As shown, a 3D powder delivery turbulence distributor with different diameters includes a distributor body, the distributor body is provided with an inlet 1, a first outlet 2 and a second outlet 3, and the distributor body is an inner diameter larger than A cavity of the inlet and outlet; the inner wall of the inlet 1, the first outlet 2 and the second outlet 3 is provided with a protruding streamlined spiral 4, and the windward side of the protruding streamlined spiral 4 is Streamlined. The inlet 1 , the first outlet 2 and the second outlet 3 are all trumpet-shaped, and the aperture area of the inlet 1 is greater than the sum of the aperture areas of the first outlet 2 and the second outlet 3 .

[0012] Protruding streamlined helix 4 is processed on the inner wall of one inlet and two outlet sections of the present invention, so that the gas-powder mixture produces a regular spiral cyclone when passing through the inlet and outlet, and the gas and dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com