Liquid flinging device

A technology of liquid rejection and liquid rejection plate, which is applied in the direction of combined device, liquid separation agent, membrane technology, etc., can solve the problems of non-adjustable movement direction, poor purification effect, and inability to produce particle size distribution mode, etc., to achieve the goal of purification effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

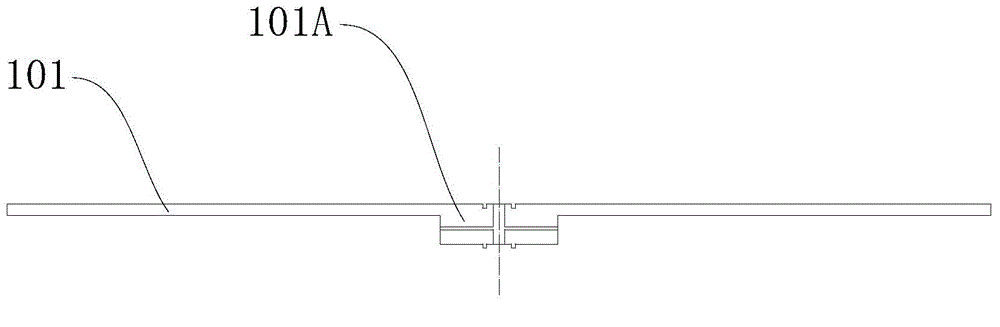

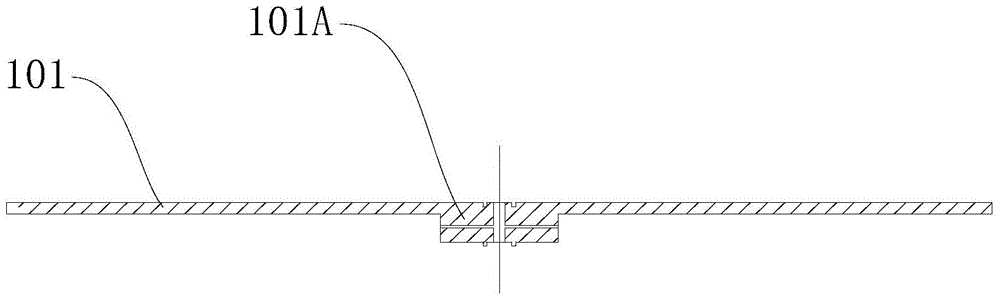

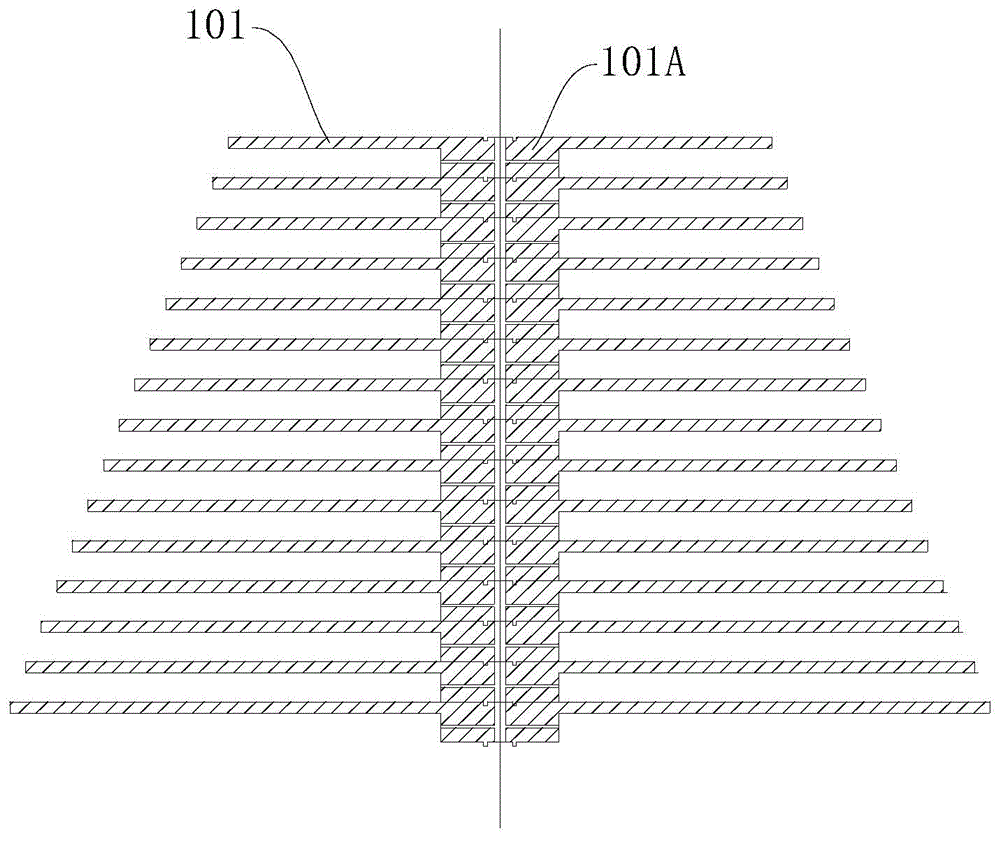

[0072] like Figure 1-Figure 4 As shown, the liquid rejection assembly includes a rotating shaft 101A and at least one liquid rejection disk 101, at least one liquid rejection disk 101 is detachably connected to the rotation shaft 101A, wherein at least one liquid rejection disk 101 is rotatable around the central axis of the rotation shaft 101A, and the rotation axis is the central axis of the rotating shaft 101A. refer to image 3 The rotating shaft 101A can be a rotating shaft 101A extending along a straight line, and can also be a rotating shaft 101A extending along a curve. The rotating axis of the rotating shaft 101A is the central axis of the rotating shaft 101A, and the central axis of the rotating shaft 101A is the rotating axis of the liquid rejection assembly.

[0073] Among them, refer to image 3 One or more liquid throwing disks 101 can be directly installed on the rotating shaft 101A, and each liquid throwing disk 101 can be driven by the rotating shaft 101A t...

Embodiment 2

[0084] like Figure 5-Figure 8As shown, the liquid rejection assembly includes a rotating shaft 102A and at least one liquid rejection brush 102, each liquid rejection brush 102 includes a plurality of bristles 1021, at least one liquid rejection brush 102 is detachably connected to the rotating shaft 102A, wherein at least one liquid rejection brush 102 is rotatable around the central axis of the rotating shaft 102A, and the rotating axis is the central axis of the rotating shaft 102A. refer to Figure 10 The rotating shaft 102A can be a rotating shaft 102A extending along a straight line, and can also be a rotating shaft 102A extending along a curve. The rotating axis of the rotating shaft 102A is the central axis of the rotating shaft 102A, and the central axis of the rotating shaft 102A is the rotating axis of the liquid rejection assembly.

[0085] Among them, refer to Figure 7 One or more liquid rejection brushes 102 can be directly installed on the rotating shaft 102...

Embodiment 3

[0096] like Figure 9 As shown, the rotating shaft 103A is formed in a hollow tubular shape, and a plurality of liquid holes are formed on the rotating shaft 103A so that the liquid can be thrown out from the plurality of liquid holes. Specifically, the rotating shaft 103A may be configured as a hollow pipeline, and a through liquid hole may be formed on the pipe wall of the rotating shaft 103A. During the rotation of the rotating shaft 103A, liquid is passed into the rotating shaft 103A. During the rotating process of the rotating shaft 103A, , the liquid in the rotating shaft 103A can be thrown out from the liquid hole on the tube wall, so that a three-dimensional droplet field 210A and / or a three-dimensional liquid film field 210B can be generated. Wherein, the predetermined distribution of the three-dimensional droplet field 210A and / or the three-dimensional liquid film field 210B can be adjusted by adjusting the rotational speed of the rotating shaft 103A and the shape an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com