Automatic cleaning equipment

A technology of automatic cleaning and equipment, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve problems such as poor cleaning effect, low cleaning efficiency, and high labor intensity, and achieve high work efficiency, The effect of improving the production efficiency of the enterprise and stabilizing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

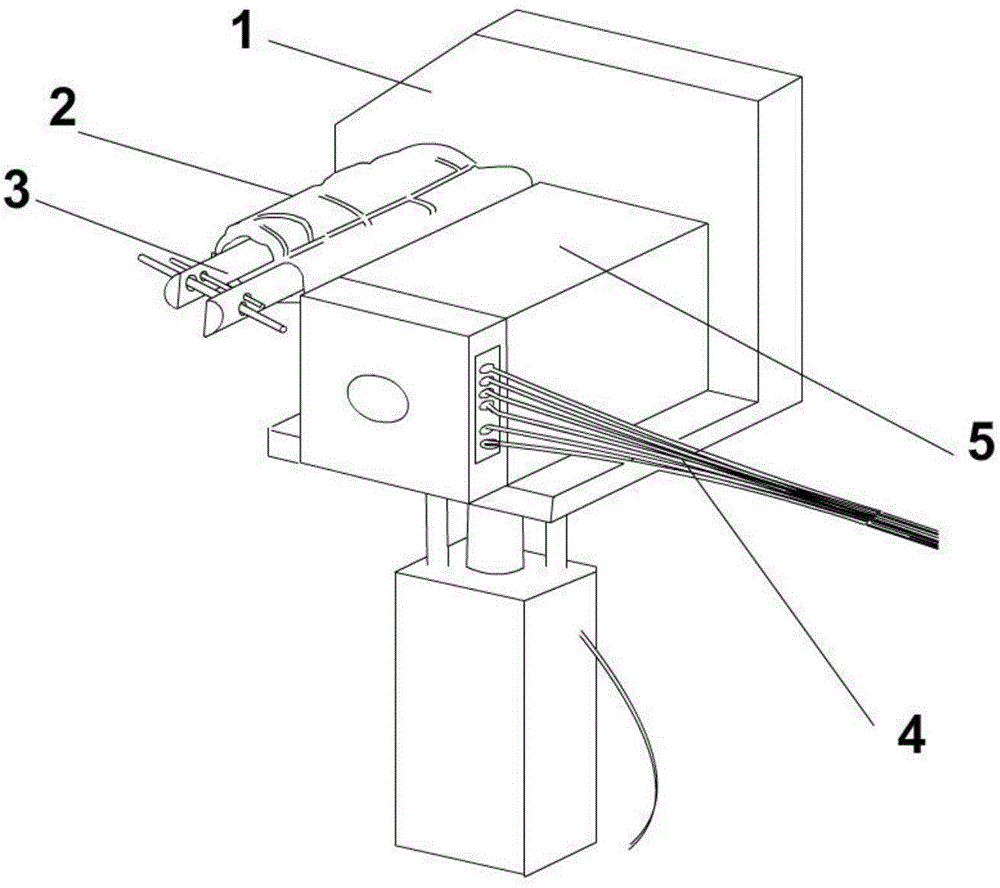

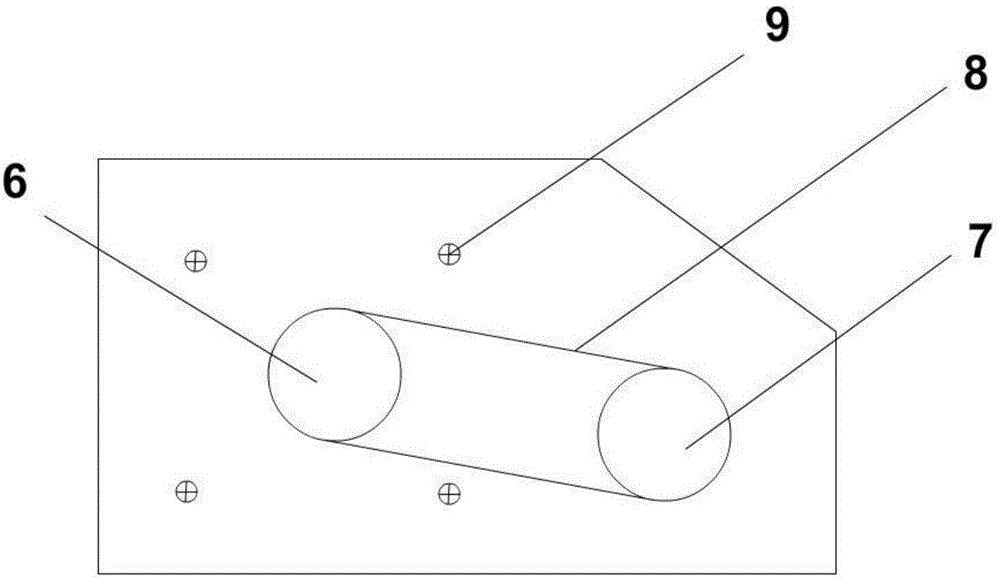

[0015] As shown in the figure: an automatic cleaning equipment, including the bracket 1, the cleaning cloth 2, the fixing clip 3, the wiring harness 4, the motor 5. As shown in the figure: the driving wheel 1, the driven wheel 2, the transmission belt 3, the screw 4; its features The cleaning cloth 2 is fixed on the fixed frame and driven by the driven wheel to rotate; the motor 5 is fixed on the bracket 1 by four screws 4 to drive the driving wheel 1 to rotate; the wire harness 4, It is connected to the power supply.

[0016] The motor 5 drives the driving wheel 1 to rotate.

[0017] The driving wheel is driven by a motor 5 which drives the driven wheel 2.

[0018] The conveyor belt 3 connects the driving wheel 1 and the driven wheel 2.

[0019] The bracket is connected with the motor and powered by a wire harness. The wire harness is composed of a power cord, a control wire, and a signal wire; the motor drives the driving wheel to rotate, the driving wheel drives the driven wheel, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com