Die

A technology between molds and molds, applied in the field of molds, can solve problems such as troublesome mold production users, failure to reach theoretical height, and difficulty in forming deep-drawing parts, and achieve the effect of simple structure and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

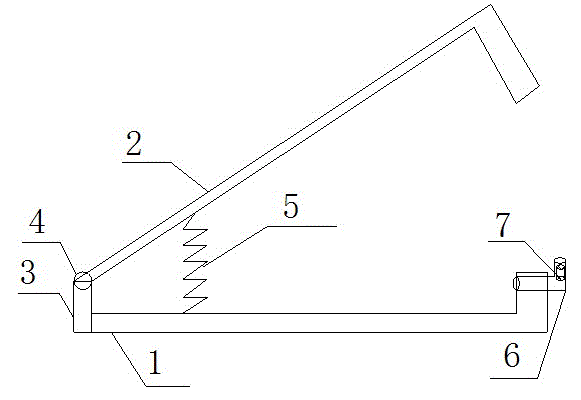

[0009] Such as figure 1 A kind of mold shown comprises mold base 1, upper mold 2 and connecting rod 3, and the left end of described mold base 1 is connected with connecting rod 3, and described upper mold 2 and connecting rod 3 are connected by movable ring 4, and described An elastic device 5 is connected between the mold base 1 and the upper mold 2, and the right end of the mold base 1 is provided with a feed inlet 6, and a feed control device 7 is arranged inside the feed inlet 6. The invention has the beneficial effects of simple structure and low manufacturing cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com