Rolling type die holder

A rolling type, mold base technology, applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of reducing production efficiency, reducing the processing speed of stamping dies, and difficulty in resetting the upper mold base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

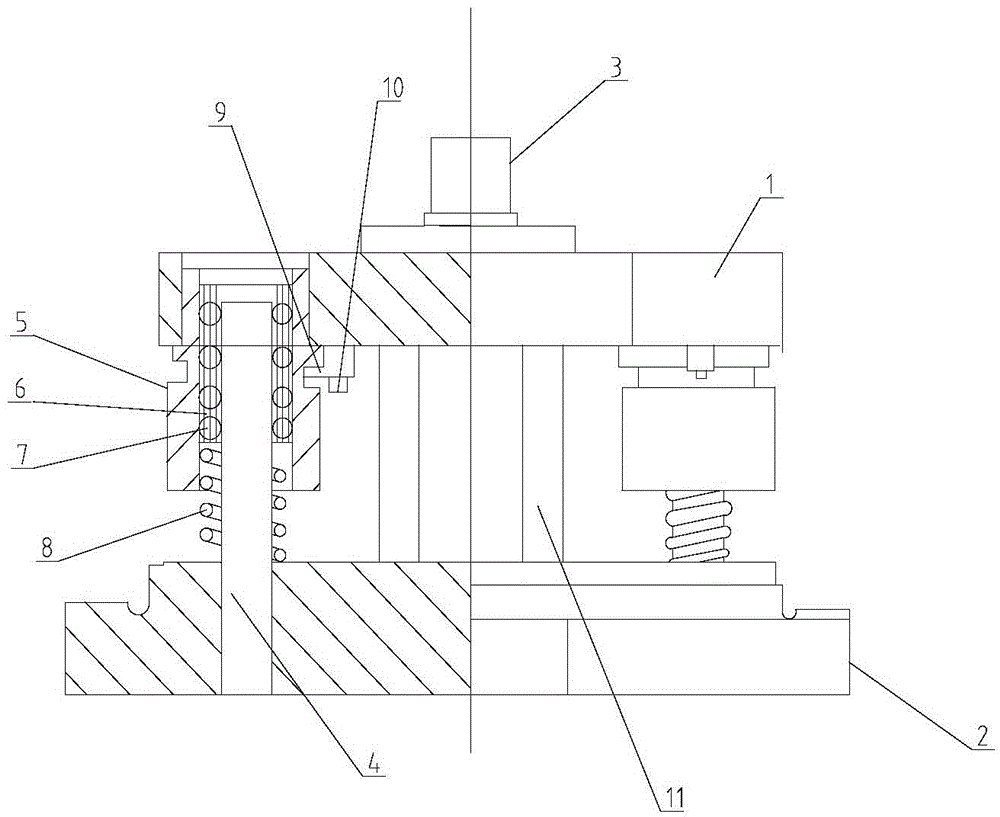

[0013] As shown in the figure, the rolling mold base includes an upper mold base 1 and a lower mold base 2. The upper mold base 1 is set on the upper end of the lower mold base 2. The upper end of the upper mold base 1 is provided with a pressure block 3. The pressure 3 is the force point. There are two guide pillars 4 between the upper and lower mold bases. The two guide pillars 4 are symmetrical to the center line of the upper and lower mold bases. When punching, the mold is prevented from tilting. The upper end of the guide pillars 4 is arranged in the upper mold base 1. Without passing through the top of the upper mold base 1, the upper part of the guide post 4 is covered with a guide sleeve 5, and a cage 6 is provided between the guide sleeve 5 and the guide post 4, and the cage 6 is connected with the guide post 4, and the cage 6 is provided with a There is a ball 7, the side of the ball 7 is in contact with the outer surface of the guide post 4 and the inner surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com