Steel pipe clamp

A clamp and steel pipe technology, which is applied in the field of clamping equipment, can solve the problems of large, inconvenient clamping of small diameter steel pipes, and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

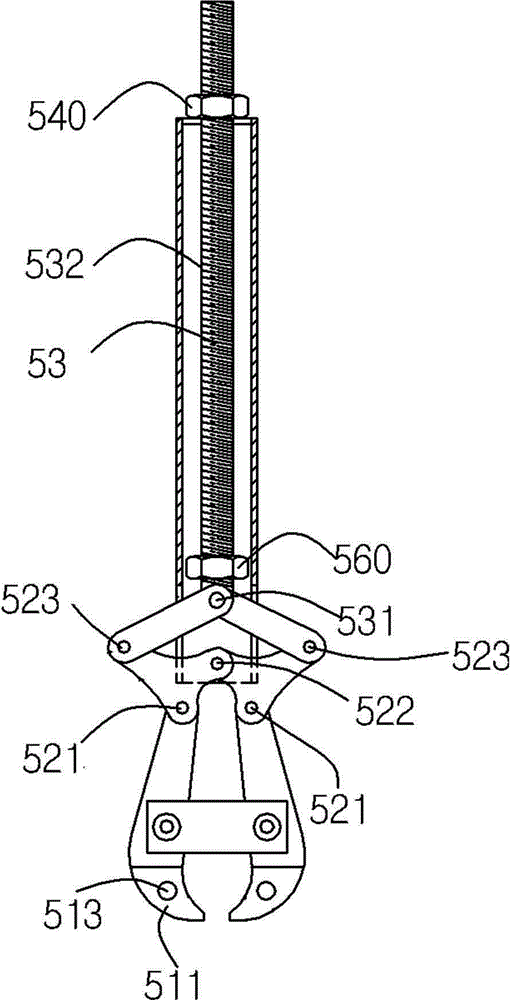

[0021] The reference signs in the drawings of the description include: the first nut 540, the threaded rod 53, the thread 532, the second nut 560, the rear hinge point 531, the middle hinge point 523, the front hinge point 522, the front end 521 of the front rod, the hanging ring 513 . The bending part 511 .

[0022] Such as figure 1 As shown, the steel pipe clamp of the present invention includes a sleeve, the front of the sleeve is provided with two opening slots opposite to each other, and the rear end of the sleeve is provided with an opening. The sleeve is made of No. 20 hot-rolled seamless steel pipe.

[0023] The sleeve is provided with a threaded rod 53, the threaded rod 53 is provided with a first nut 540 and a second nut 560, the threaded rod 53 passes through the hole into the sleeve, and is locked in by the first nut 540 The rear end of the sleeve and the f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap