Broach for heat exchanging tube

A heat exchange tube and broach technology, applied in broach, broach, broach devices, etc., can solve the problems of poor cutting uniformity and low cutting efficiency, achieve good cutting uniformity, improve cutting efficiency, and facilitate setting and viewing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

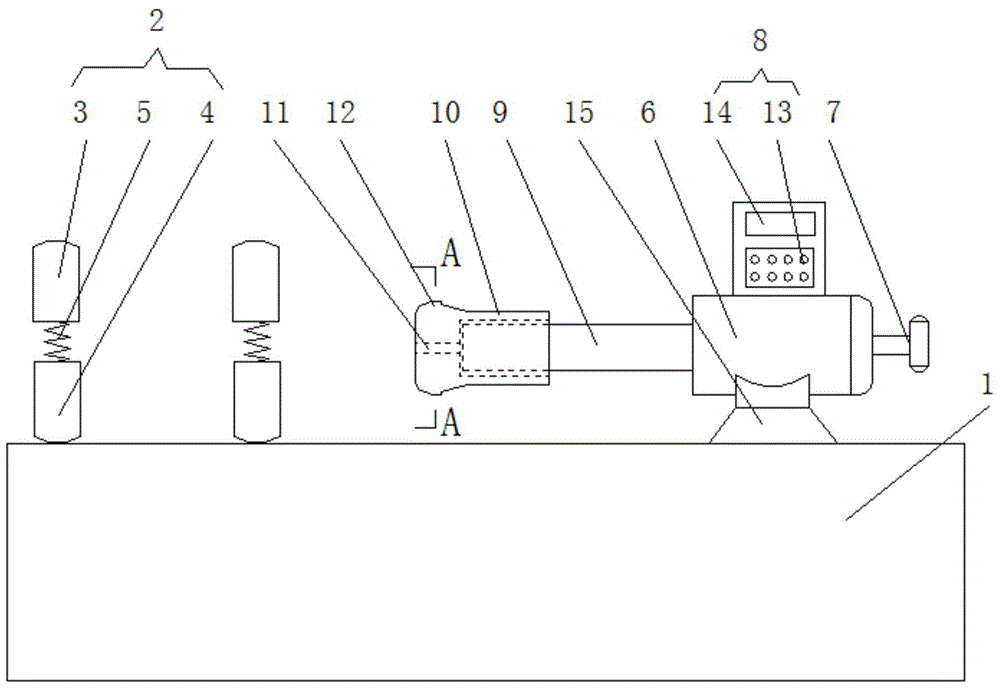

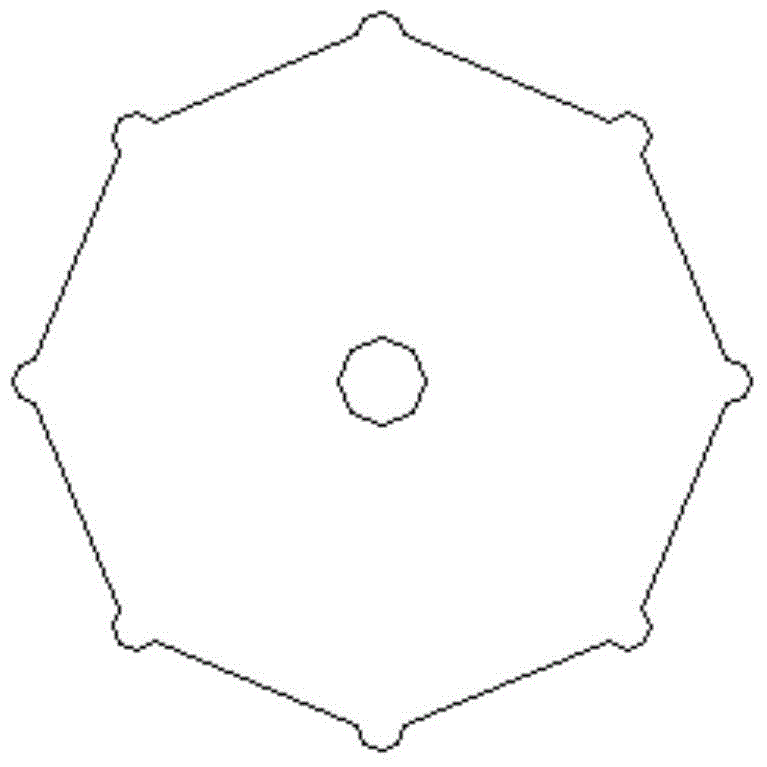

[0020] Such as Figure 1-Figure 2 As shown, this embodiment includes a processing table 1, a pipe clamp 2, an upper half ring 3, a lower half ring 4, a spring 5, a linear motor 6, a rotary handle 7, a positioning device 8, a telescopic push rod 9, a cutter body 10, and a channel 11 and cutter head 12, pipe clamp 2 is installed on the upper left part of processing table 1, pipe clamp 2 includes upper half ring 3, lower half ring 4 and spring 5, lower half ring 4 is fixed on the processing table 1, lower half ring The two sides of 4 are connected to the upper half ring 3 through the spring 5. There are two pipe clamps 2. The distance between the pipe clamps 2 is consistent with the length of the telescopic push rod 9. The upper right part of the processing table 1 is fixed. There is a linear motor 6, a rotating handle 7 is installed in the middle part of the rear side of the linear motor 6, a positioning device 8 is arranged on the upper side of the linear motor 6, and the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com