A semi-automatic strip food slicing device

A slicing device and semi-automatic technology, applied in metal processing and other directions, can solve the problems of being unsuitable for large-scale food cutting and industrial production, difficult to grasp uniform thickness, and low manual cutting efficiency, and achieve flexible adjustment of cutting thickness and high cutting efficiency. , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

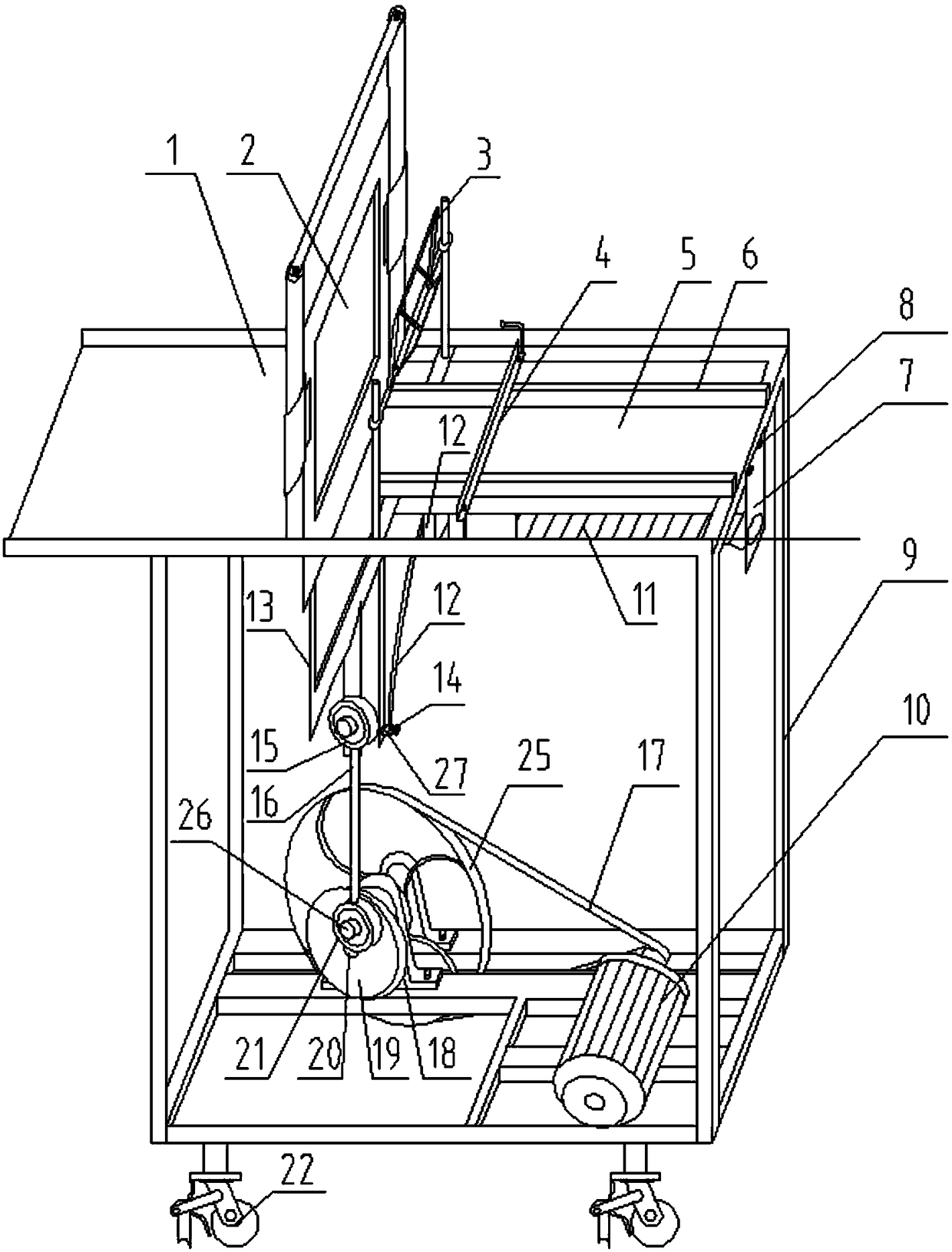

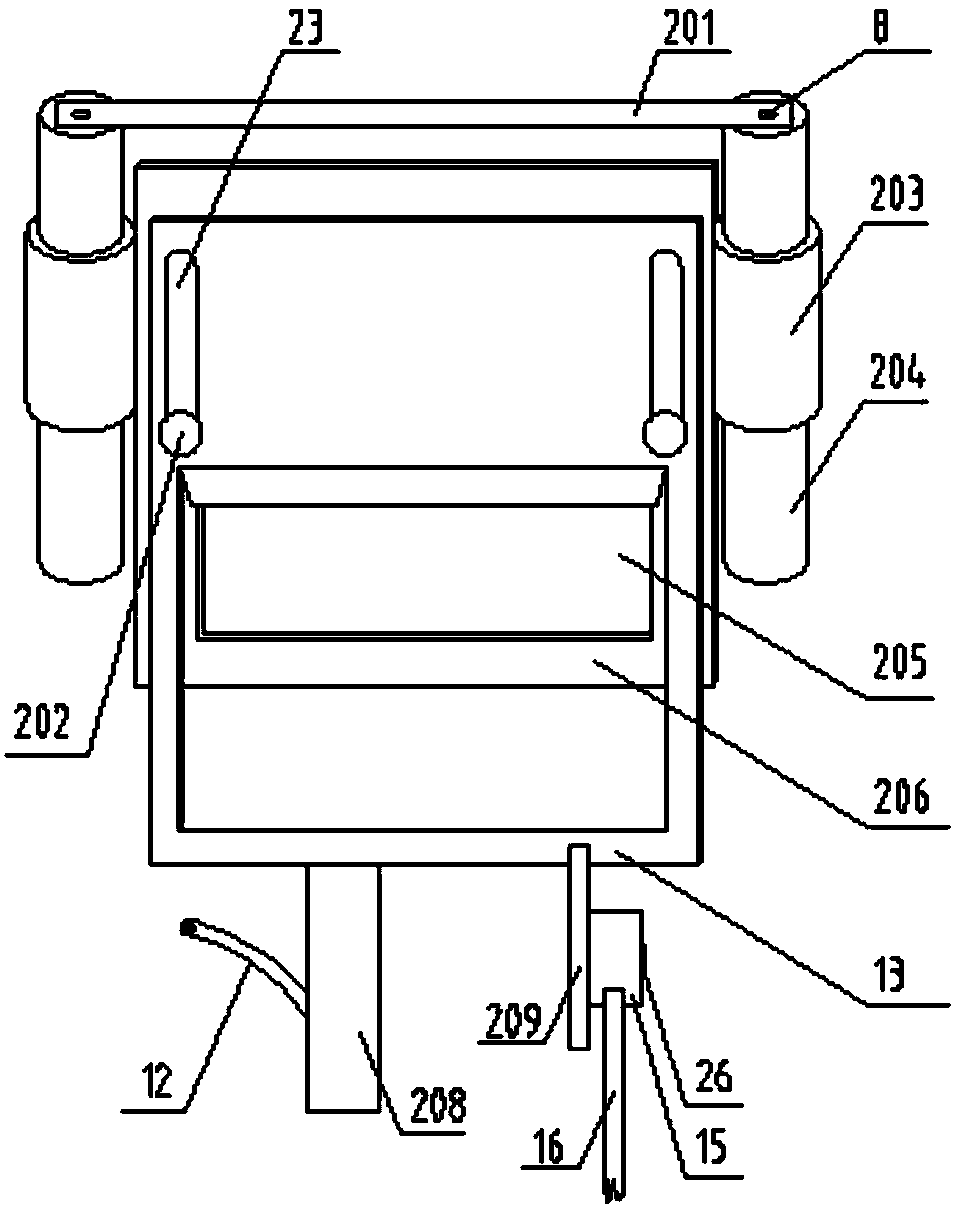

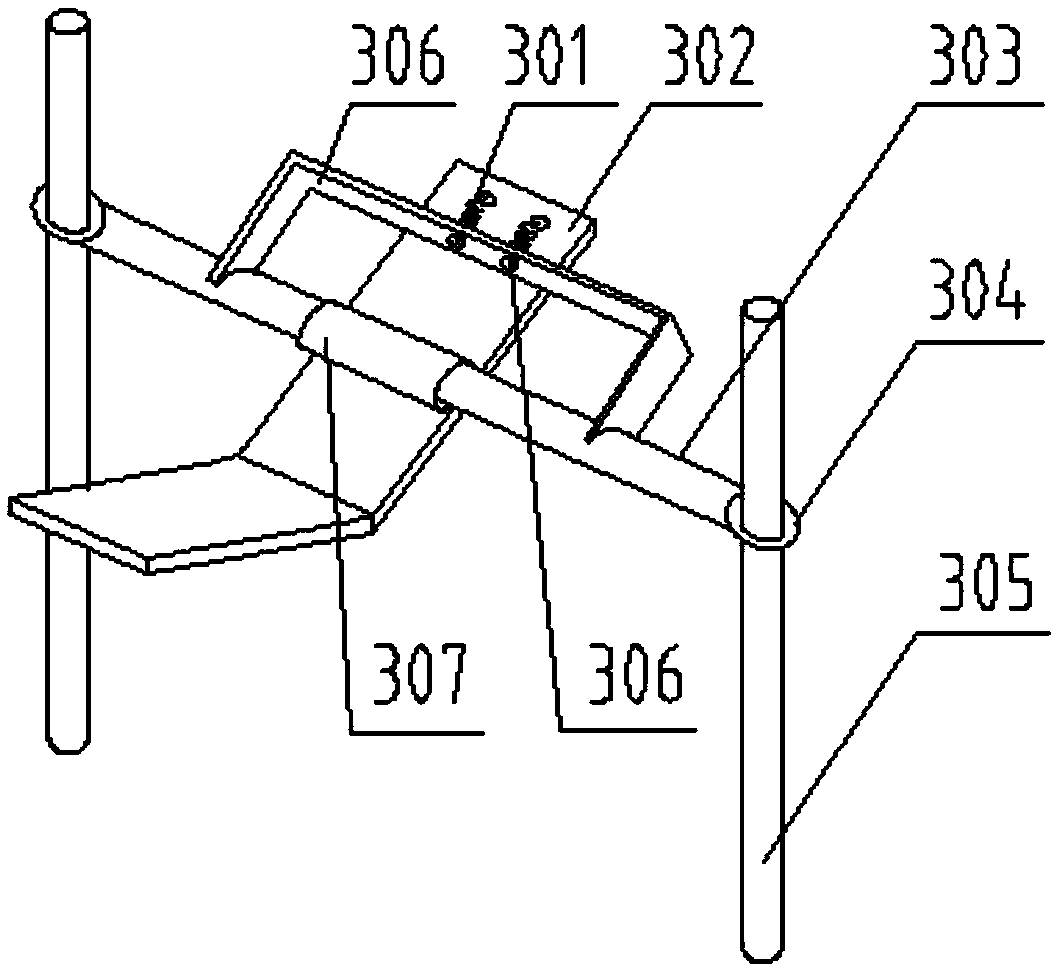

[0018]The main structure of the semi-automatic strip-shaped food slicing device involved in this embodiment includes: a discharge tray 1, a cutting blade fixing device 2, a clamping device 3, a propulsion device 4, a feeding tray 5, a guide rail 6, a screw fixing plate 7, Fixing bolt 8, frame 9, motor 10, screw rod 11, screw rod connecting rod 12, cutting blade 13, connecting block 14, first transmission bearing 15, bearing connecting rod 16, transmission belt 17, fixed seat 18, eccentric wheel 19, fixed shaft 20. The second transmission bearing 21, the wheel 22, the blade fixing hole 23, the screw fixing frame 24, the main transmission wheel 25, the bearing connection cylinder 26 and the sleeve hole 27; the upper surface of the frame 9 composed of a plurality of support rods is left A discharge tray 1 is fixed on the side. The discharge tray 1 is a smooth planar structure to catch the cut materials. The cutting blade fixing device 2 is fixed on the right side of the discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com