A kind of dry preparation system and process of cotton fiber for pulping

A cotton fiber and process technology, which is applied in the field of cotton fiber raw material papermaking and cotton fiber raw material papermaking in the field of material preparation, can solve the problems of low technical index requirements of the finished product after cutting, non-uniform cutting of cotton fibers, longitudinal arrangement of cotton fibers, and the like, Achieve the effect of improving bleachability and evenness, reducing pulping costs and reducing production consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a dry preparation system for cotton fibers for pulping, which includes a cleaning system, cotton fiber longitudinal finishing equipment and a cutting machine, and the cleaning system is connected to the cotton fiber vertical finishing equipment through air delivery equipment , the cotton fiber longitudinal finishing equipment is connected with the cutting machine through the conveyor belt.

[0032] The working width of the cotton fiber longitudinal finishing equipment (carding machine) is more than 1.5m.

[0033] The number of moving blades of the cutting machine is 20-40 pieces.

[0034] The motor speed of the cutting machine is 1000 rpm.

[0035] The feeding speed of the conveyor belt is above 150m / min.

Embodiment 2

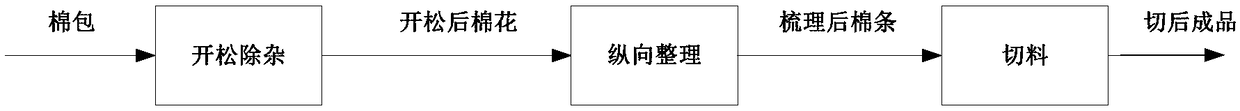

[0037] This embodiment provides a kind of dry preparation process of cotton fiber for pulping, which is realized by adopting the dry preparation system of cotton fiber for pulping in Example 1. The process flow diagram is as follows figure 1 As shown, it includes the following steps:

[0038] Raw material: comb noil, production capacity is 10 tons;

[0039] First, use the cleaning system to loosen and remove impurities from the loose cotton bales, and then use the cotton fiber longitudinal finishing equipment to carry out longitudinal finishing on the opened cotton to make it discharge in the form of cotton sliver, and then use the cutting machine to process the cotton sliver The material is cut to realize the uniform cutting of the cotton fiber in a dry process to obtain the dry cut cotton fiber, the dry cut cotton fiber contains only 0.2-0.5 wt% of impurities (calculated based on the total weight of the dry cut cotton fiber).

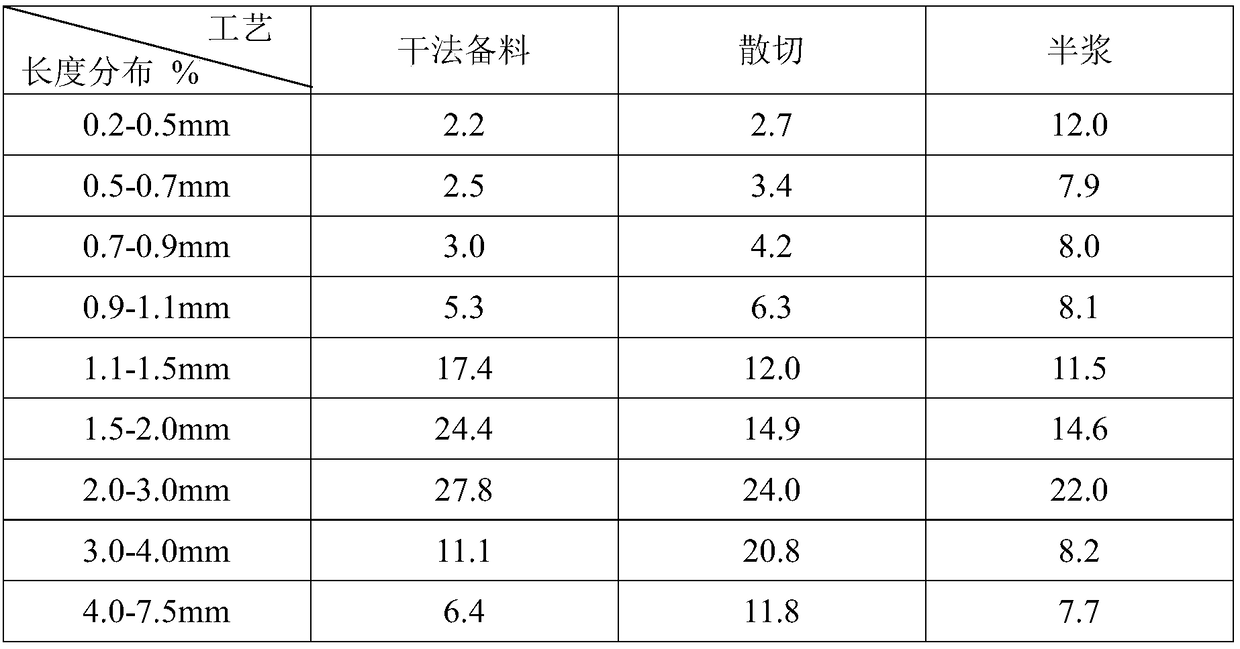

[0040] Measure respectively the fiber length d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com