Cutting device in use for line of cooling film

A cooling line, film technology, applied in applications, household appliances, other household appliances, etc., can solve the problems of uneven cutting, continuous film cutting, low cutting efficiency, etc., to achieve compact and simple structure, straight and accurate incision, The effect of accurate and stable position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

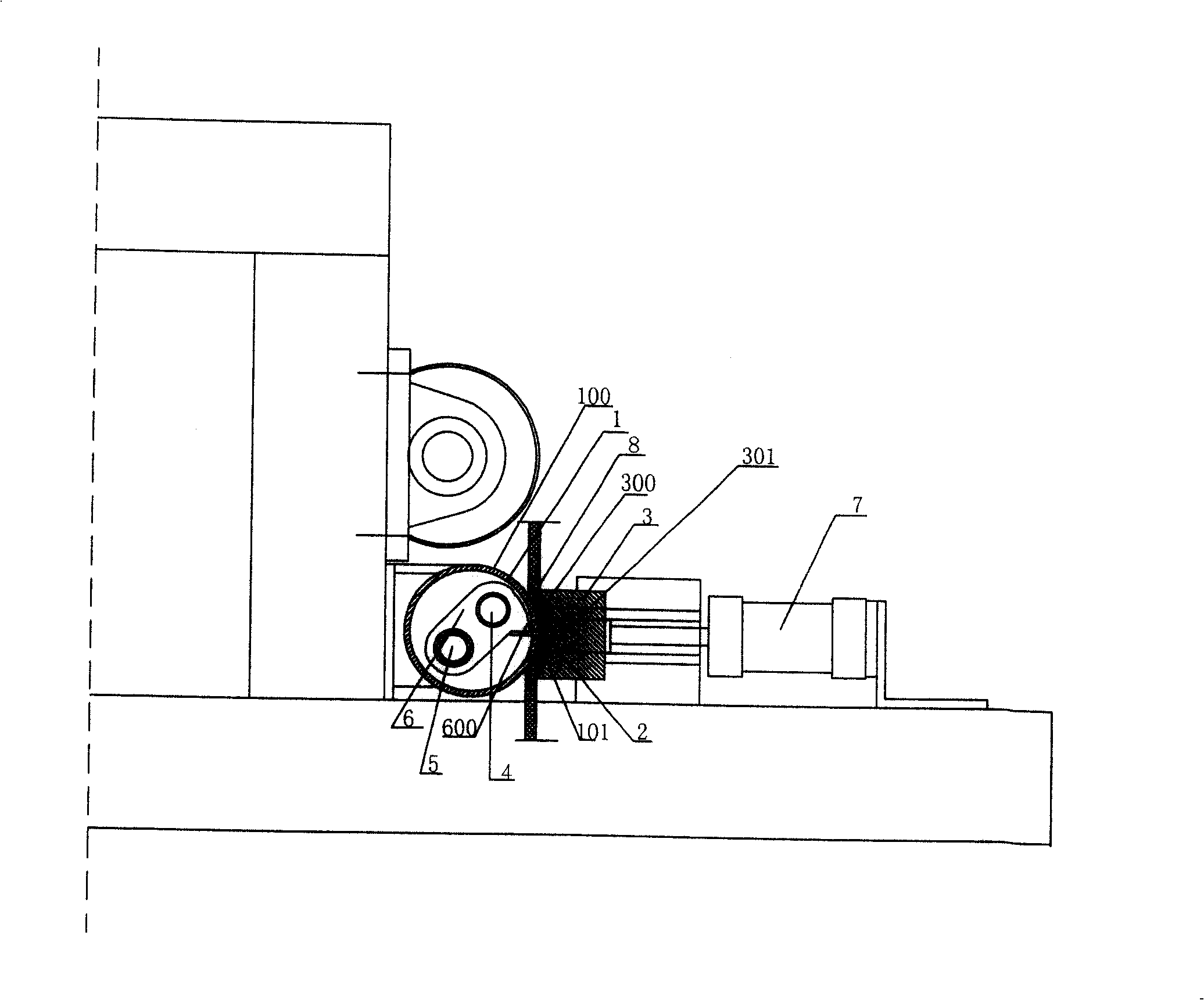

[0015] Combined with the figure, a cutting device for film cooling line, the static support part 1 of the film clamping mechanism is cylindrical, the cylinder wall is provided with a cutting knife notch 101 extending along the length direction, the dynamic pressure of the film clamping mechanism The part 3 is plate-shaped, and the dynamic pressure part 3 is equipped with a direct-acting push-pull device 7, which can be an air cylinder or a hydraulic oil cylinder, and its pressing surface 300 is an arc-shaped surface suitable for the outer cylinder wall 100 of the static support part. On the side of the pressing surface of the dynamic pressure part 3, there is a cutter head receiving notch 301 extending along the length direction directly opposite to the position of the cutter notch, and the dynamic pressure part 3 can be driven by the action of the straight-moving push-pull device 7. The pressure part 3 presses the film to be cut to the direction of the static support part 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com