Special clamp for multi-directionally clamping frame workpieces

A special fixture and frame technology, applied in the direction of manufacturing tools, metal processing machinery parts, clamping and other directions, can solve the problems of affecting the machining accuracy, the pressure loss of the frame workpiece, and the low qualified rate of the finished product, so as to avoid movement and improve processing. The effect of precision, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

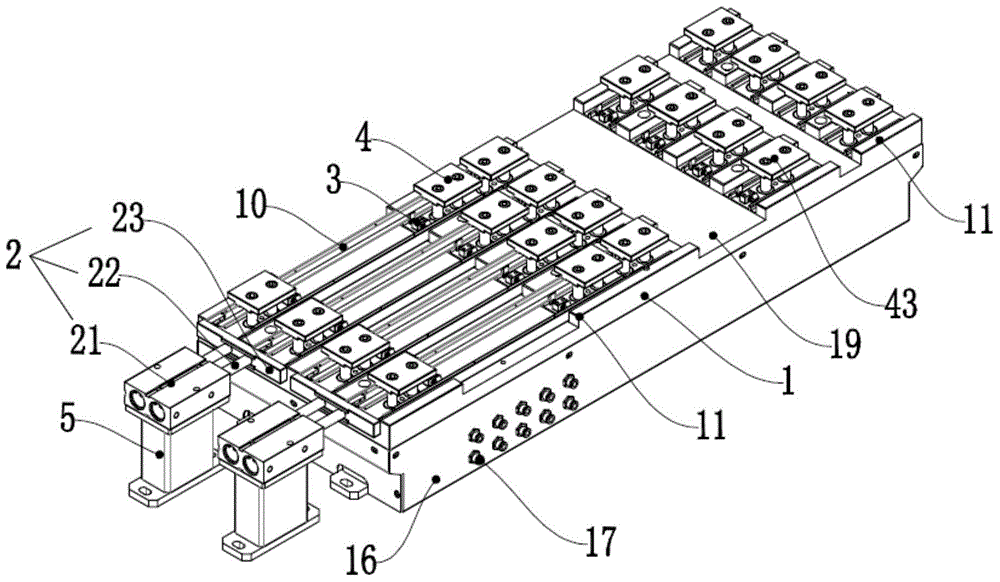

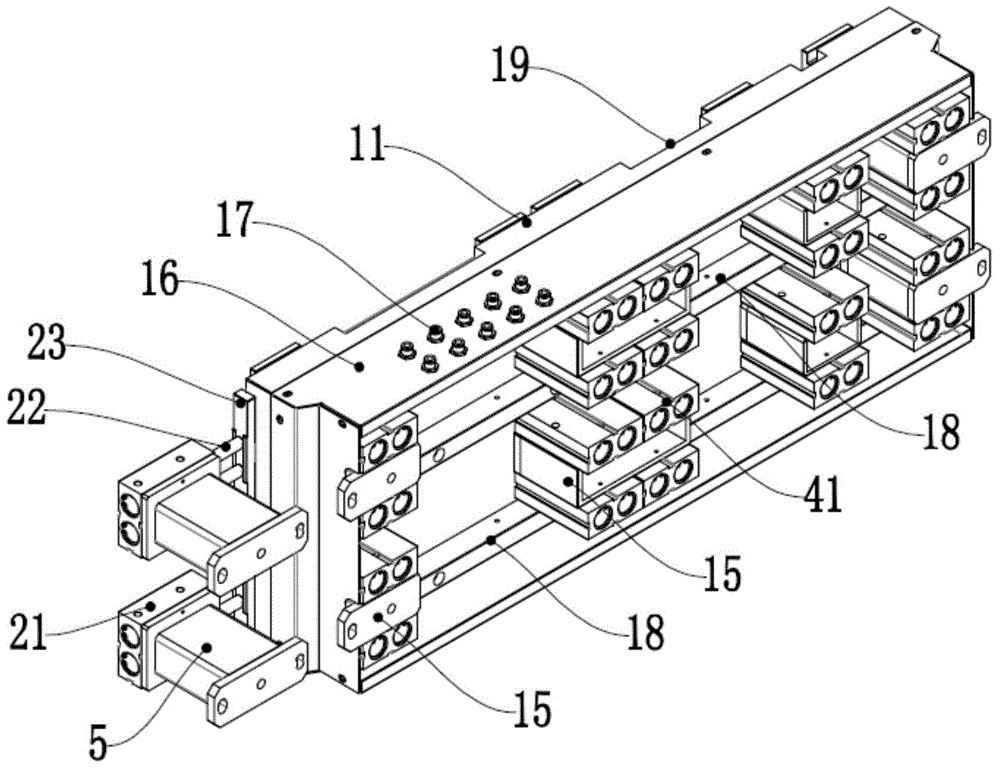

[0027] A special fixture for multi-directional clamping of frame workpieces, including a base plate 1, multiple Y-direction automatic positioning devices 3 and multiple Z-direction positioning devices 4;

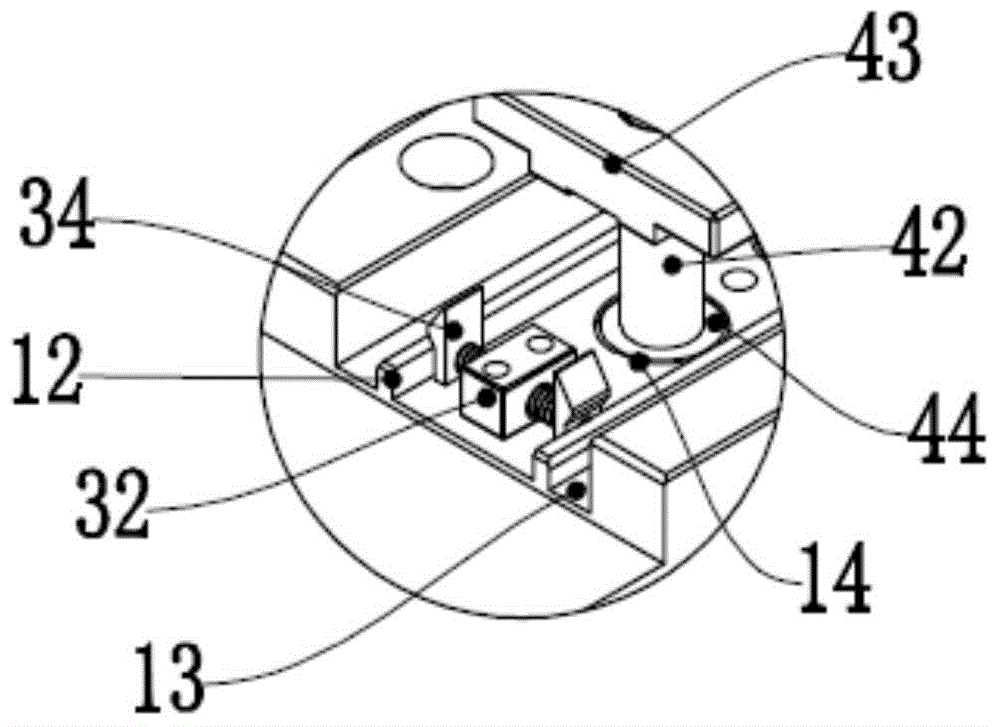

[0028] A row or more than one row of segmented clamping grooves 11 is horizontally arranged on the working table of the base plate 1, and the frame workpieces 10 are respectively placed on both sides of the grooves in the lateral direction of the clamping grooves 11. , the groove bottom surface of the clamping groove 11 is provided with a plurality of slot holes 14 for installing the positioning device along the position of the transverse centerline in the groove;

[0029] The Y-direction positioning device 3 is arranged on the groove surface of the clamping groove 11 through the slot hole 14, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com