Thermal shield tool clamp

A technology of tooling fixtures and heat shields, which is applied in the direction of manufacturing tools and workpiece clamping devices, can solve problems such as complex structure of heat shield positioning tooling, hidden dangers of personal safety of operators, and inability to ensure assembly accuracy, etc., to achieve simple structure, The effect of low cost and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

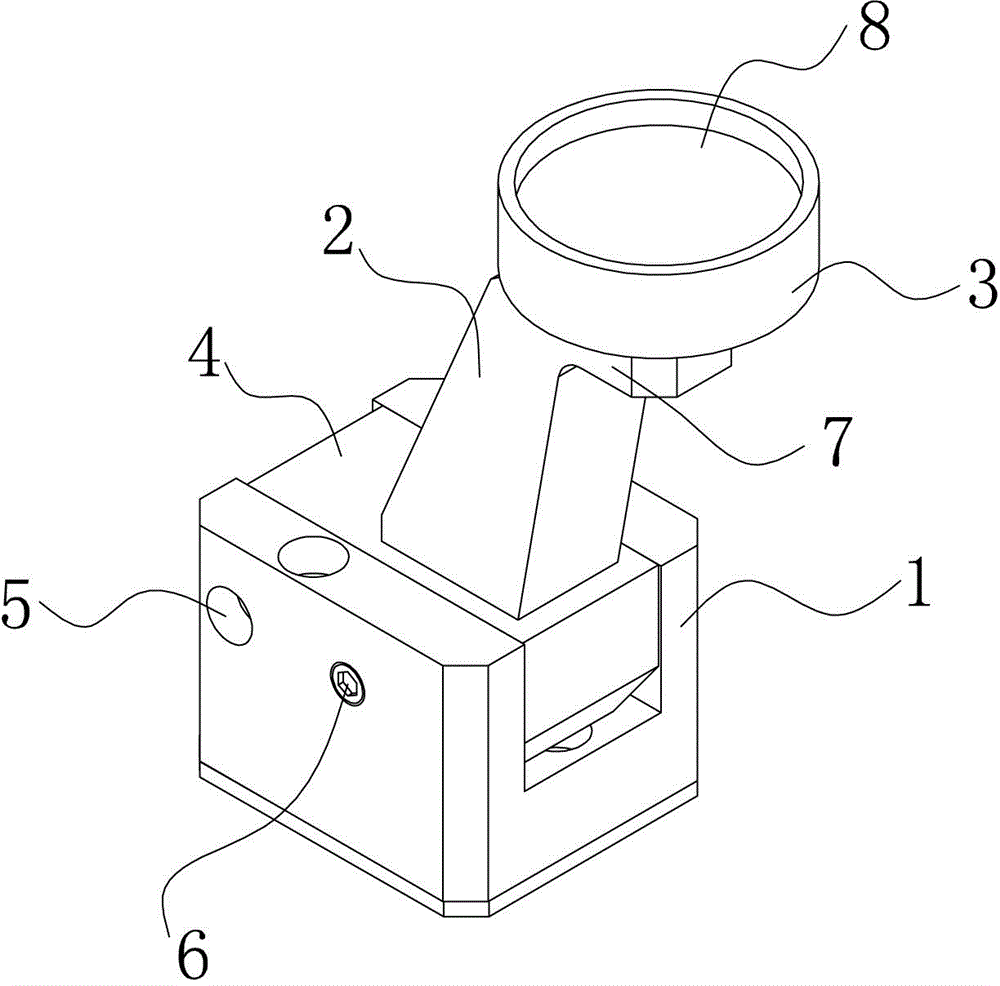

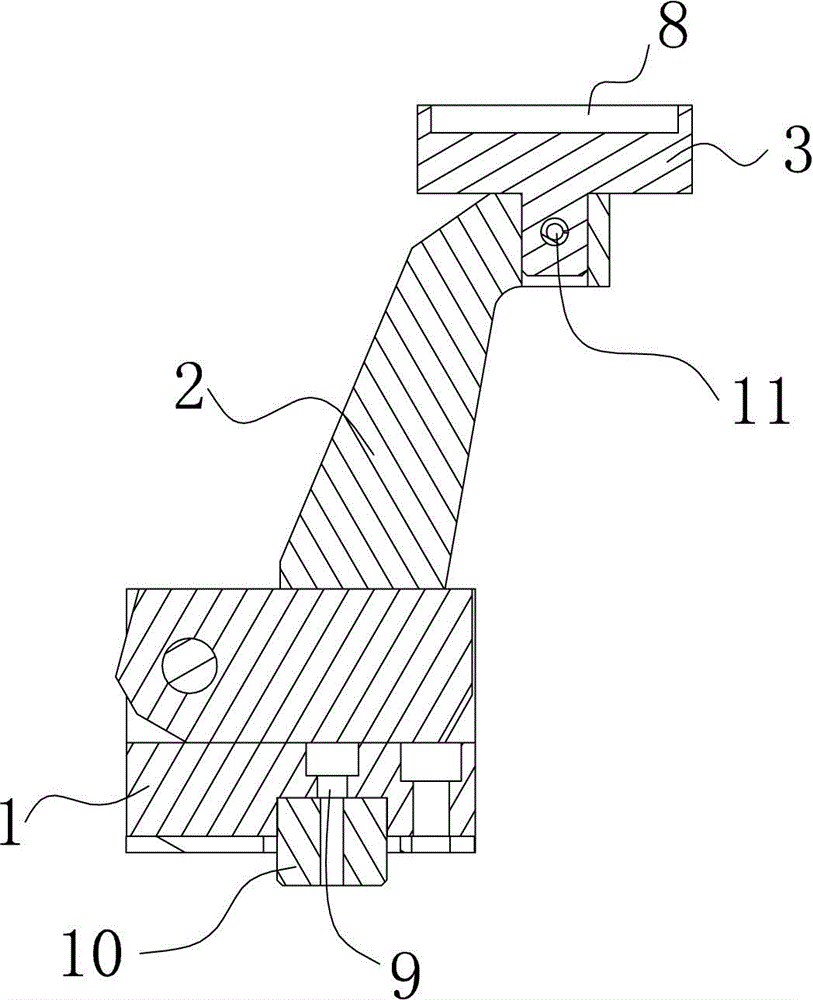

[0012] Such as Figure 1-2 As shown, a heat shield fixture described in the embodiment of the present invention mainly includes a base 1, a bracket 2 and a support block 3, the base 1 is a square body, a square groove is arranged in the middle of the base 1, and one end of the bracket 2 It is the socket block 4, and the socket block 4 is plugged in the square groove. A spring pin 6 and a rotating shaft 5 are arranged at the joint between the socket block 4 and the base 1. There is an angle between the bracket 2 and the top surface of the base 1. In the bracket The top end of 2 is provided with a horizontal extension 7, one end of the support block 3 is inserted into the horizontal extension 7 and fixed by a positioning pin 11, the other end of the support block 3 is disc-shaped, and the top of the support block 3 is provided with a depression 8, A countersunk hole is arranged in the square groove, and the base 1 is connected with a positioning post 10 through a screw 9 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com