An Improved Passenger Car Window

A technology for car windows and passenger cars, applied to windows, vehicle parts, vehicle safety arrangements, etc., can solve the problems of threatening the life safety of passengers, the windows are not easy to open, and the escape opportunity is delayed, and achieves long service life, strong external structure, and operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

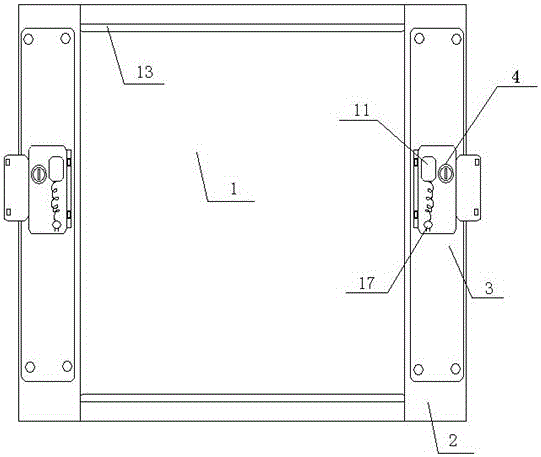

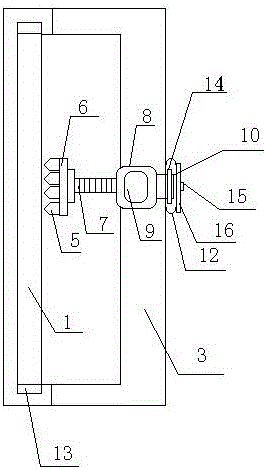

[0014] The present invention as figure 1 and figure 2 Shown: an improved passenger car window, including a tempered window 1 and a window frame 2, the tempered window 1 is arranged in the window frame 2, and both sides of the inner surface of the window frame 2 are connected with the installation fixing plate 3, the The electric cone 4 is installed in the fixed plate 3, and the electric cone 4 includes the cone head 5. The cone head 5 adopts a row structure, and the tempered window can be strengthened by the multi-drill bits of the row structure in case of accidents such as fire. The destructive force of 1 is convenient for escape. Since the corner part of the tempered window 1 is easy to be damaged, the cone head 5 of the electric cone 4 is close to the inner edge of the tempered window 1, and the cone head 5 is connected with one end of the high-speed rotor 6 and the telescopic traction rod 7 The other end of the telescopic traction rod 7 is provided with a miniature high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com