A self-loading truck compartment

A technology for unloading trucks and carriages, which is applied in the arrangement of loading and unloading vehicles, vehicles used for freight, the superstructure of trucks, etc., can solve the problem of not being able to carry shelves on the vehicle, increasing the cost of goods transportation, and inefficient hydraulic walls, etc. problems, to avoid loading inconvenience, improve loading efficiency, and facilitate hoisting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

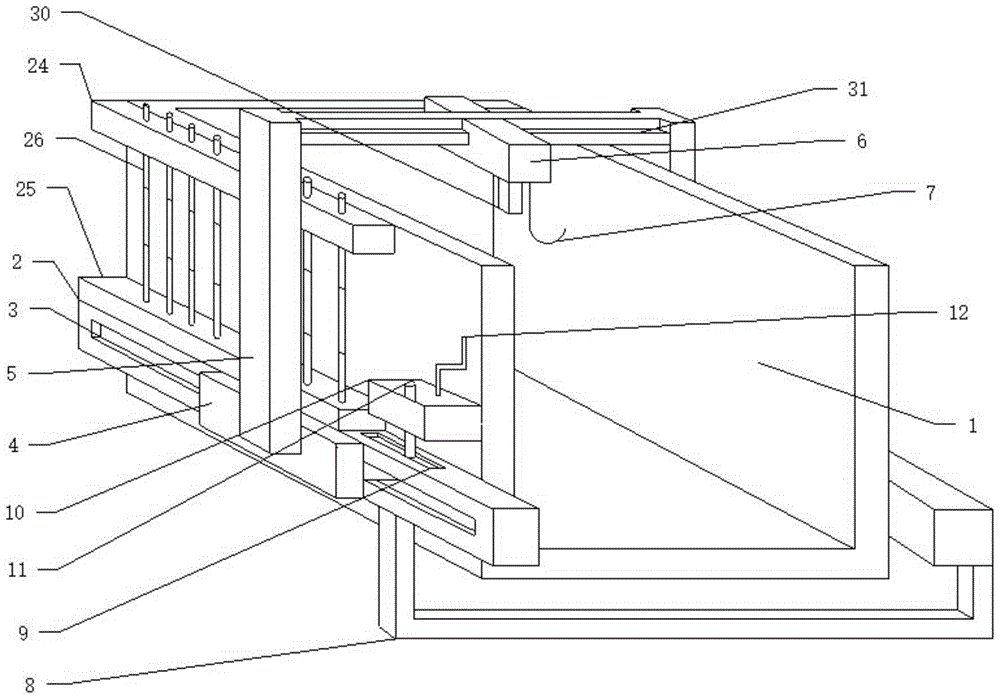

[0033] like figure 1 As shown, a self-loading truck compartment includes a compartment 1, a cylindrical T-shaped sliding seat 23 is respectively provided at the center of both sides of the bottom of the compartment 1, and a sliding movable seat 23 is respectively provided on the T-shaped sliding seat 23. The base 2, the movable bases 2 on both sides are correspondingly connected through the connecting frame 8.

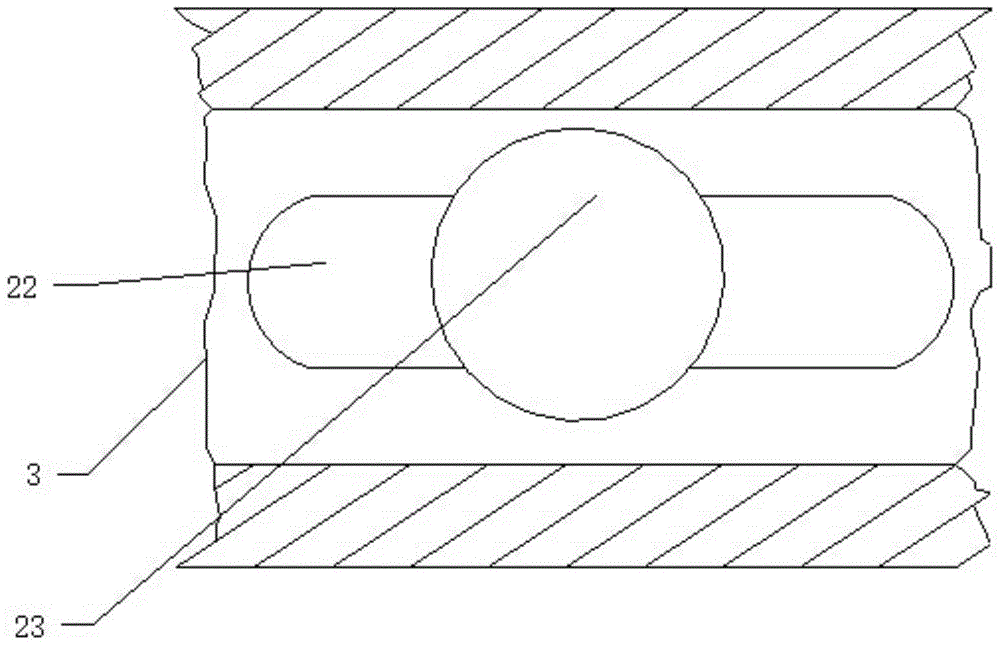

[0034] like image 3 and Figure 4 As shown, wherein the center of the movable base 2 is provided with an oblong sliding groove 22, and the end diameter of the T-shaped sliding seat 23 is greater than the width of the oblong sliding groove 22.

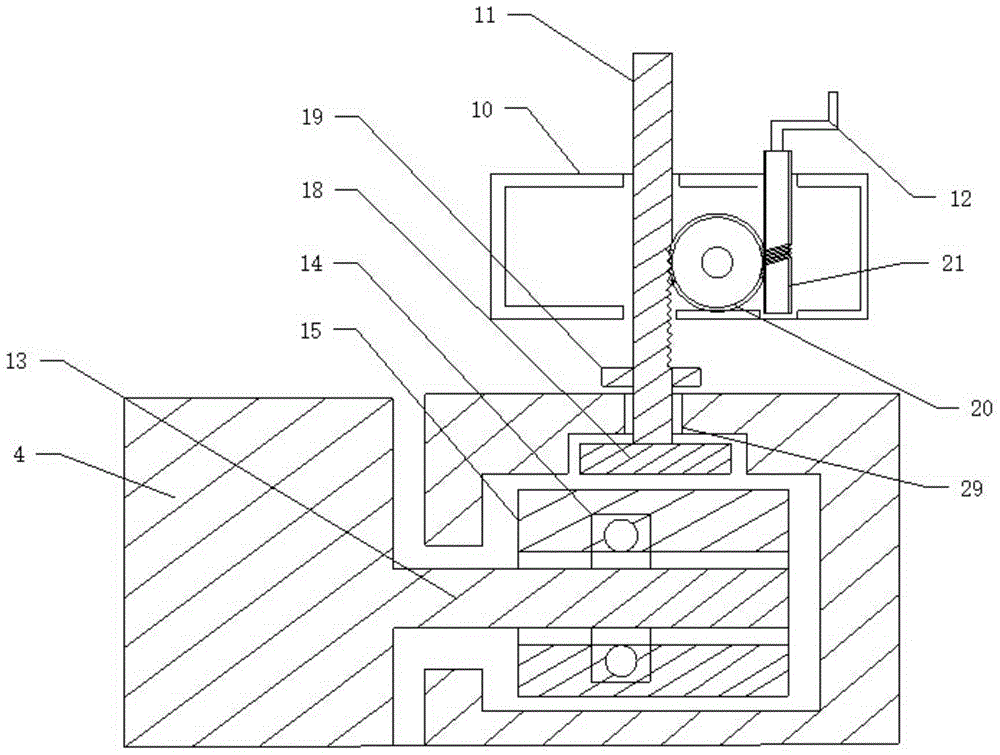

[0035] During use, the movable base 2 is correspondingly connected together by using the connecting frame 8, which can drive the movable base 2 on the other side to move simultaneously while pulling the movable base 2 on one side, so that the movable base 2 on both sides can work at the same time, and utilize The oblong chut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com