Switch point closure detector

A technology for sticking checkers and turnouts, which is applied to the locking mechanism of turnouts, railway car body parts, railway signals, etc., can solve the problems of unsuitable center rail installation, poor impact resistance, and indicating rod movement, etc. To achieve the effect of reducing the number of varieties and spare parts, good sealing performance and less maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

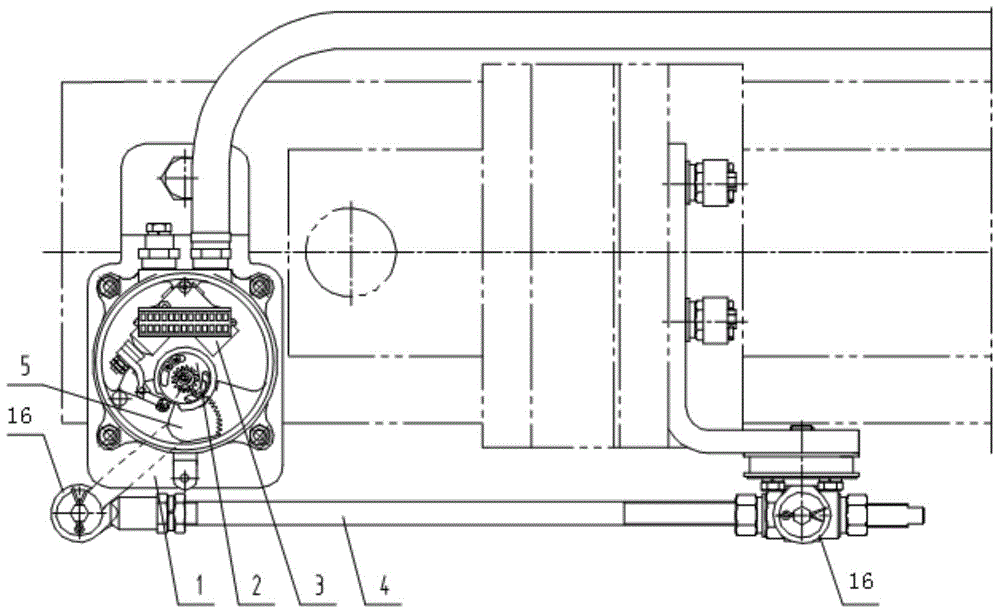

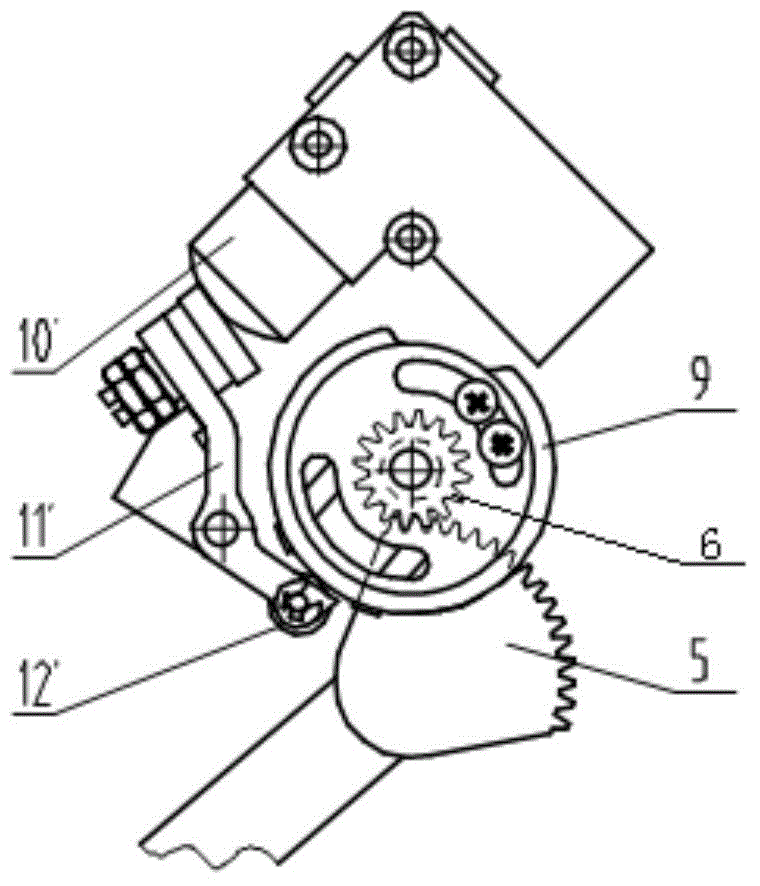

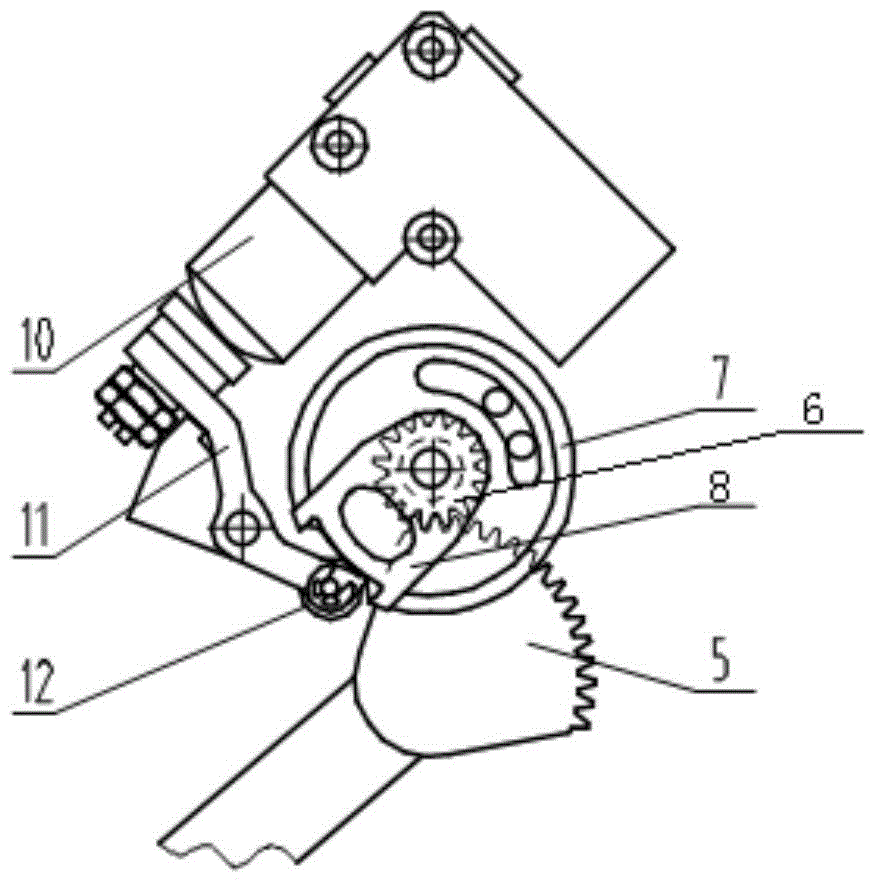

[0027] The present invention is applicable to turnouts of electric centralized railway stations. It adopts the circular design of the axial rotation mechanism, changes the linear motion mode of the previous close-fit checker, and uses the connecting rod mechanism to convert the linear displacement of the point rail into rotary motion through the gear, and then through the gear The transmission changes the contact on and off to achieve the purpose of checking whether the tip rail and the basic rail or the center rail and the wing rail are in close contact, and whether the repelling rail is in place.

[0028] Refer to attached figure 1 A top view schematic diagram of a turnout closeness checker installed on one side of a turnout. The turnout closeness checker of the present invention is installed between two traction points on one side of a turnout, including a base 1, a rotating mechanism 2, a contact group 3, and a connecting rod group 4 .

[0029] Refer to attached Figures...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com