Supporting chain wheel for track-laying vehicle

A crawler type and chain carrier technology, applied in the field of carrier rollers, can solve the problems of increasing the use and maintenance costs of tracked vehicles, complex internal structure of the carrier roller, uneven force on the carrier roller, etc., so as to avoid deformation or even breakage. , good support, the effect of reducing the cost of use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for the purpose of illustration only, and in no way limits the invention and its application or usage.

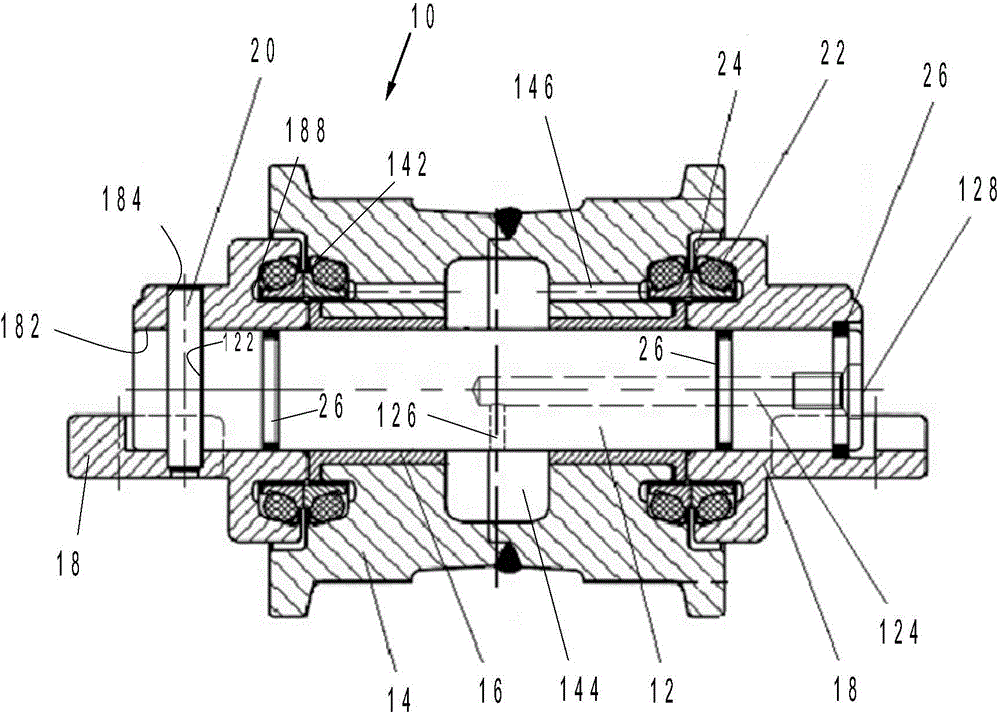

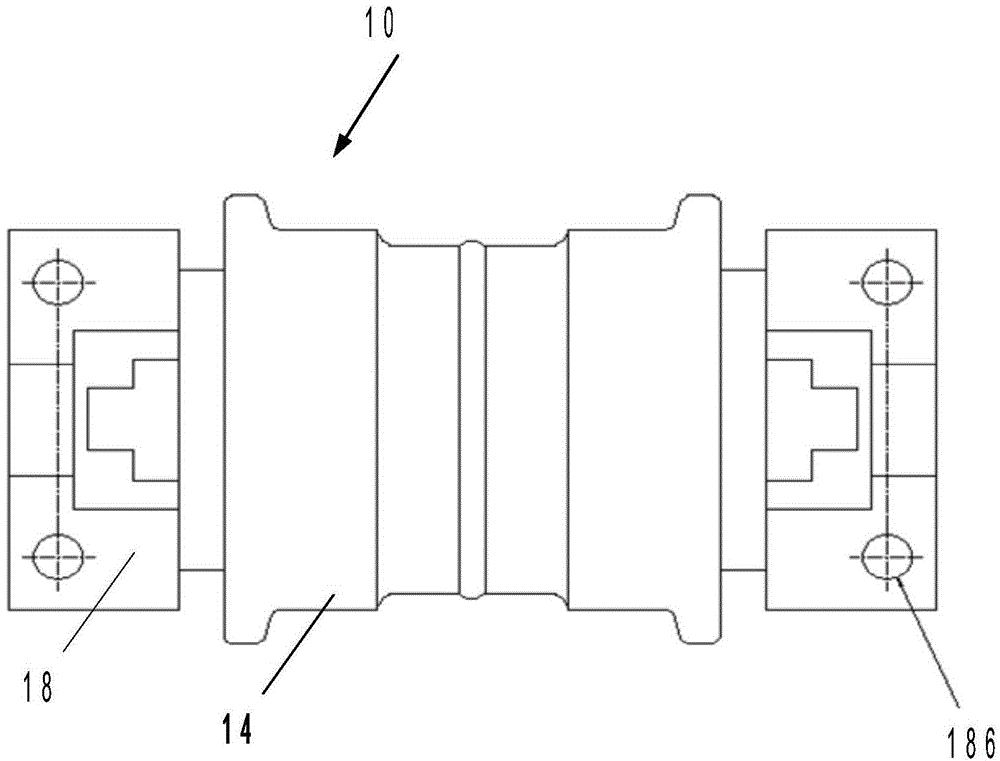

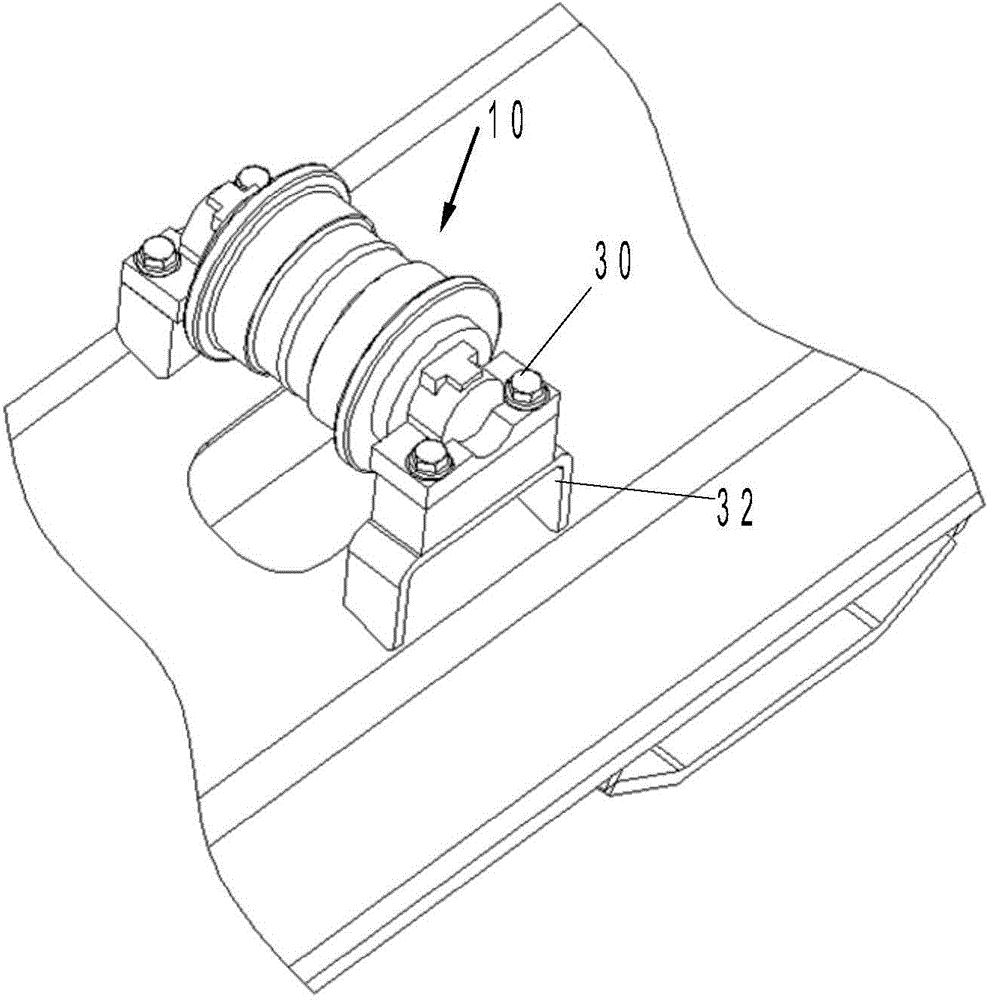

[0021] attached figure 1 A sectional view of a carrier roller 10 for supporting a track in a tracked vehicle such as an excavator according to the present invention is shown. Refer to the attached figure 1 The specific structure of the carrier roller 10 for supporting the track according to the present invention will be described in detail. The carrier roller 10 according to the present invention includes a main shaft 12 and a wheel body 14 rotatably provided on an outer peripheral wall of the main shaft 12 . The main shaft 12 supports the wheel body 14, and when the wheel body 14 supports the crawler belt, the wheel body 14 can rotate around the main shaft 12 during the running of the tracked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com