Front lower load beam turnover tooling

A front and lower bearing beam and tooling technology, which is applied in the directions of transportation and packaging, containers and containers to prevent mechanical damage, etc., can solve the problems of the front and lower bearing beams, such as large amount of labor and labor intensity, and inconvenient storage of storage racks. The effect of reducing workload and working intensity, good storage stability and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

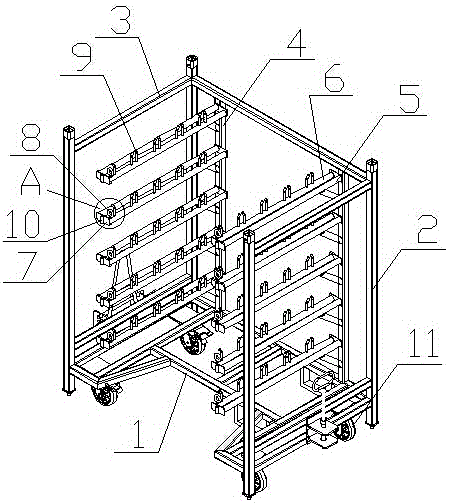

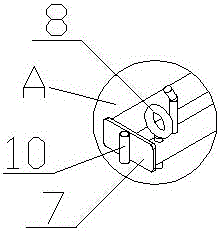

[0016] Example: see figure 1 , figure 2 , a turnaround tool for the front and lower load-bearing beams, comprising a rectangular bottom frame 1 and four uprights 2, the uprights 2 are fixedly connected to the four corners of the bottom frame 1, the two ends of the bottom frame 1 between the two uprights 2 and the bottom bracket A connecting rod 3 is respectively arranged between the two uprights 2 on one side of the frame 1, and the two ends of the connecting rod 3 are connected with the upper end of the upright 2, so that the upright 2 and the connecting rod 3 form a frame with one side open; The frame 1 has a gap near the open side of the frame. The storage and removal of the front and lower load-bearing beams from the open car makes the operation more convenient and fast, thereby improving the storage efficiency. Four rollers 11 are arranged under the bottom bracket frame 1, and the rollers 11 are respectively located at the four corners of the bottom bracket frame 1. Du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com