Rotating disc mechanism

A turntable mechanism and turntable technology, used in rotary conveyors, conveyors, transportation and packaging, etc., can solve the problems of inconvenient operation, slow speed, increase the company's production cost, etc., and achieve the effect of improving rotation stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

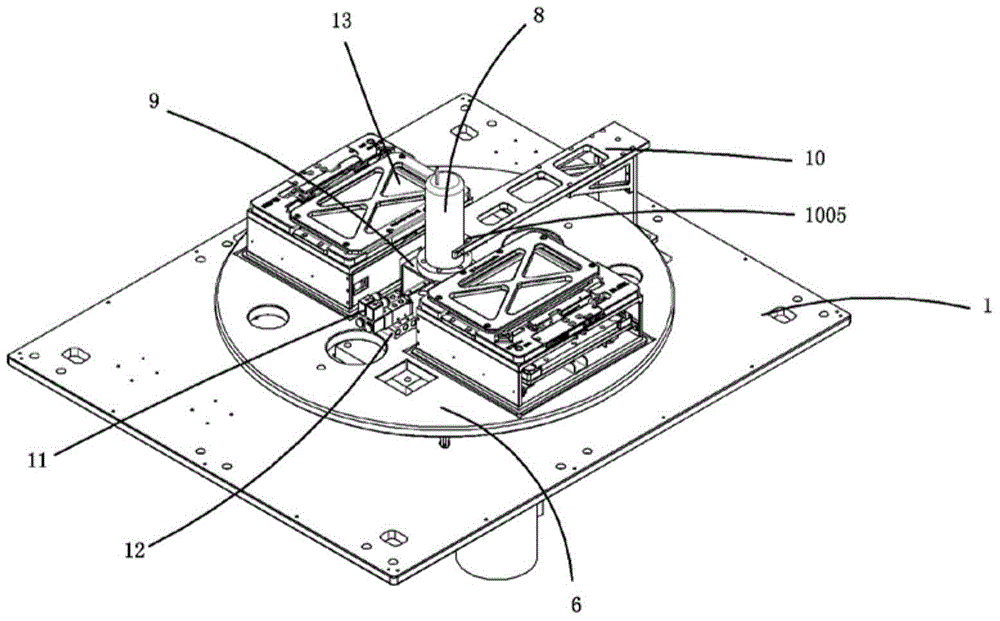

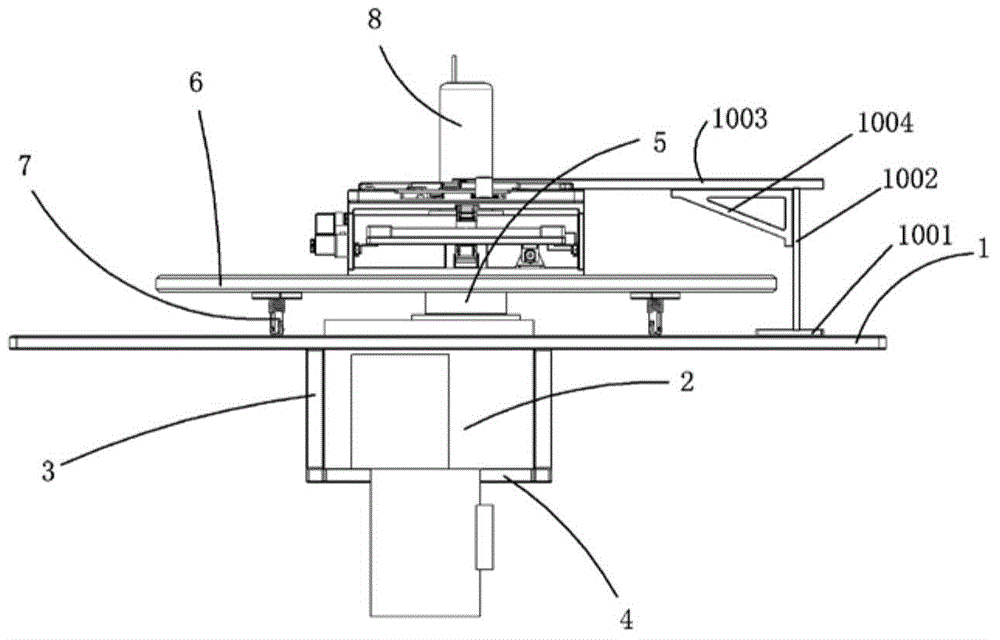

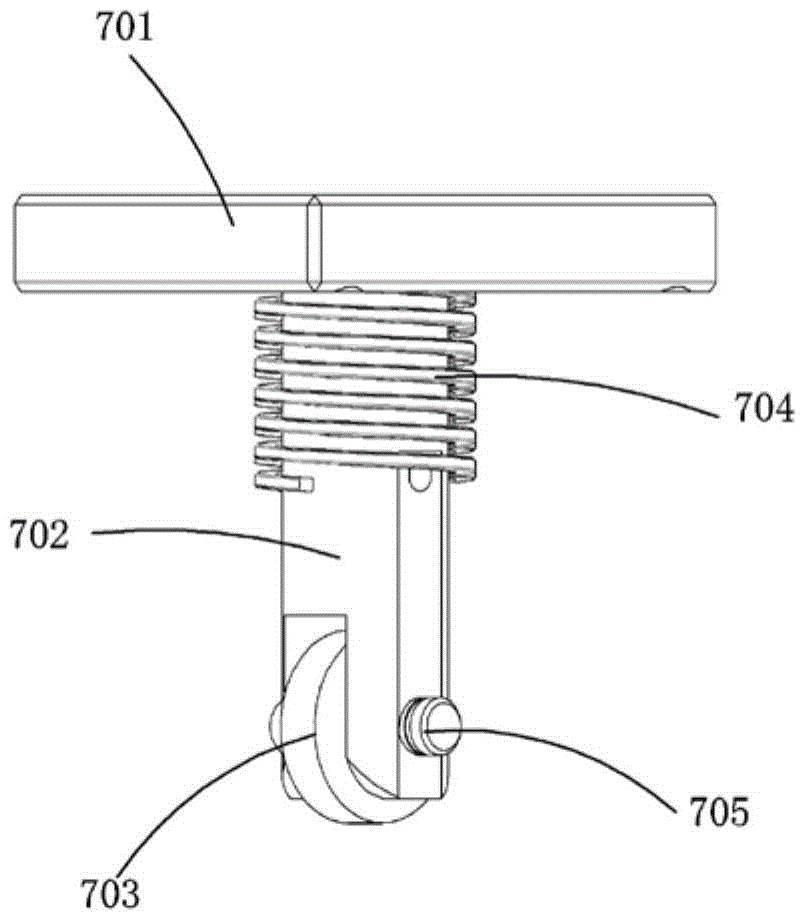

[0016] Examples, see attached Figure 1~3 , a turntable mechanism, which includes a bottom plate 1, a cam divider 2, a divider side fixed plate 3, a divider bottom fixed plate 4, a rotating connection block 5, a turntable 6, a guide caster 7, a conductive slip ring 8, a conductive slip ring Fixed frame 9, conductive slip ring stop device 10, solenoid valve 11, solenoid valve fixing seat 12 and carrier device 13, the cam divider is installed on the lower part of the base plate through two divider side fixing plates and divider bottom fixing plate ;The turntable is installed on the output end of the cam divider through the rotating connection block to realize the intermittent rotation of the index, and the rotation angle is grasped through the cam divider; four groups of guide casters are symmetrically installed on the bottom of the turntable, and the guide casters can be placed on the bottom plate Sliding; two carrier devices are symmetrically installed on the upper part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com