Wire winding disc and steel bar binding machine

A wire reel and wire reel technology, which is applied in construction, building construction, and building material processing, can solve the problems affecting the normal use of the machine, the beginning end of the steel wire is easy to enter the machine, and the beginning end of the steel wire is not fixed firmly. Saves maintenance and cleanup time, reduces likelihood, enhances fixation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

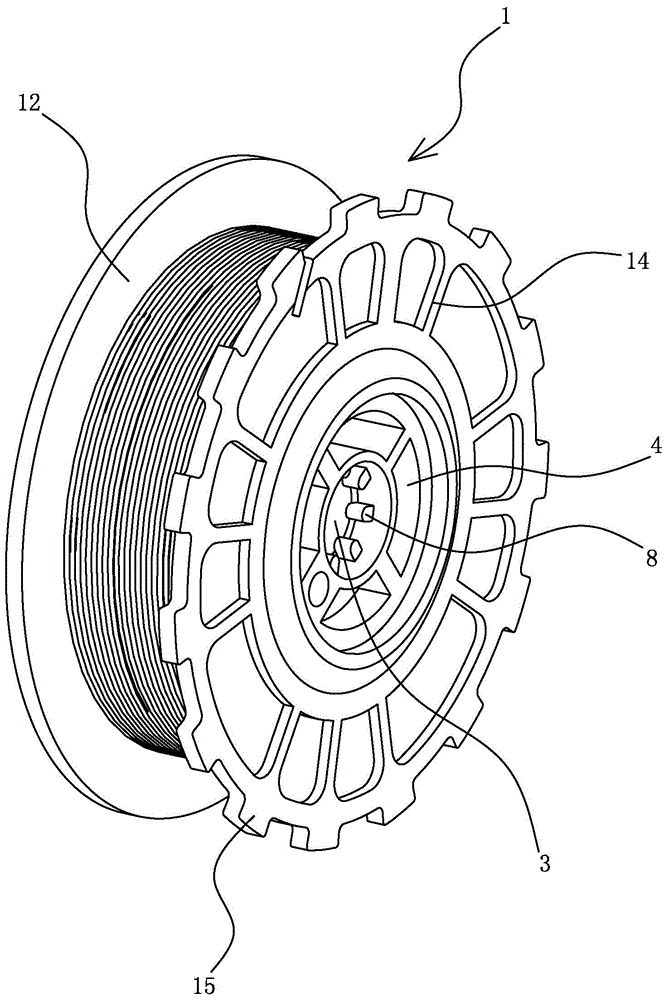

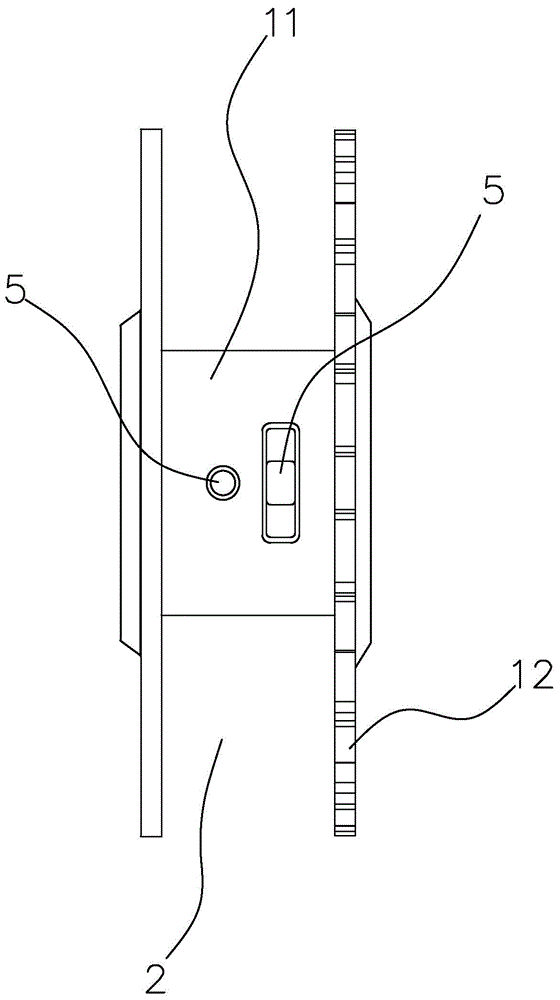

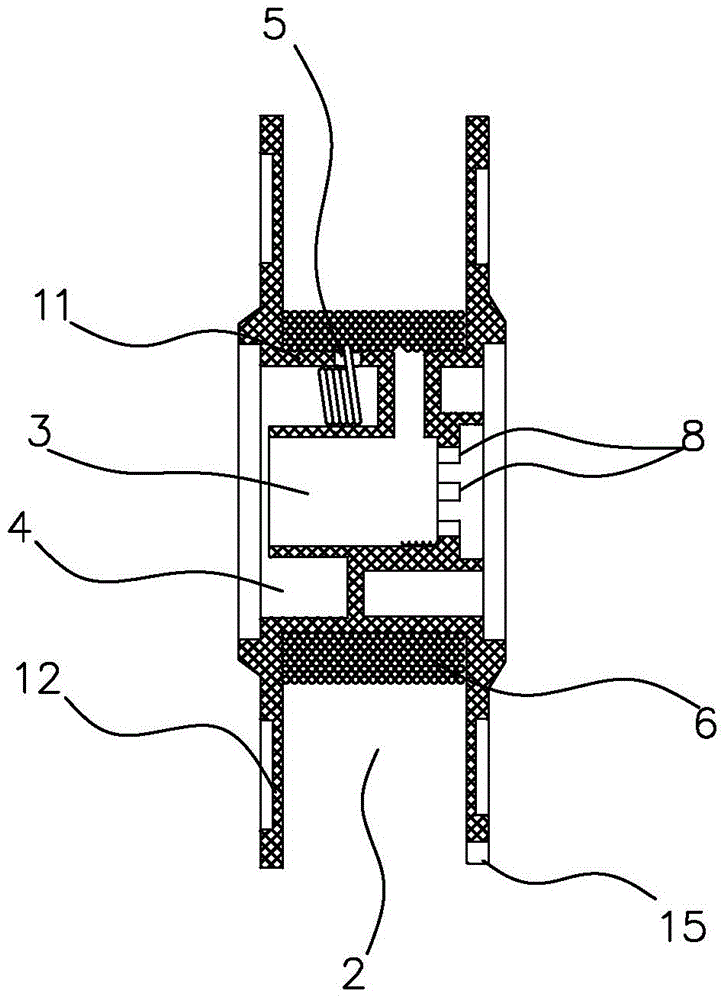

[0028] see Figure 1 to Figure 3 According to the winding reel provided by the present invention, the through hole 5 is provided as one, and the through hole 5 communicates with the annular structure 4 or the installation hole 3, and the through hole 5 of the present invention can also pass through The annular structure 4 communicates with the installation hole 3, and the present invention provides one through hole 5 on the shaft sleeve 11, the annular structure 4 is connected with the through hole 5, and the beginning end of the steel wire 6 passes through the through hole 5 and enters the Annulus structure 4, the end of steel wire 6 is knotted in annulus structure 4, and is wound into a multi-turn knot with a diameter larger than through hole 5, so that after the steel wire 6 on the wire coil is used up or not enough When performing the next bundling, the knotting part of the steel wire can be clamped on the through hole 5, effectively preventing the beginning end of the ste...

Embodiment 2

[0030] see Figure 1 to Figure 4 According to the wire reel provided by the present invention, the present invention also provides another embodiment of a through hole 5 opened on the shaft sleeve 11, the through hole 5 is communicated with the installation hole 3, and the beginning end of the steel wire 6 passes through the through hole 5. The hole 5 enters the installation hole 3, and is knotted at the middle position of the installation hole 3 to form a knot with a diameter larger than the diameter of the through hole 5. The above-mentioned middle position is located at the middle position of the two ends of the installation hole 3. When it is used up or not enough for the next binding, the end of the steel wire 6 can be clamped on the through hole 6, effectively preventing the beginning of the steel wire from falling off from the wire reel and entering the machine to affect the work of the machine itself Next, when the winding reel is installed on the binding machine or ot...

Embodiment 3

[0032] see Figure 1 to Figure 4 , according to the winding reel provided by the present invention, the present invention also provides a third embodiment of the through hole 5 provided on the sleeve 11, the through hole 5 is set to two, and the two through holes 5 are respectively connected with The annular structure 4 communicates with the installation hole 3, and the starting end of the steel wire 6 can pass through one of the through holes 5 to be knotted in the installation hole 3 or the annular structure 4 to form a knot with a diameter larger than the diameter of the through hole 5 part, also can first pass through one of the through holes 5 for knotting, then pass through another through hole 5 for secondary knotting to form a knotted part with a diameter greater than the diameter of the through hole 5, and the reinforcing steel wire 6 is about to be used up or It is not enough for the fixing effect of the next binding, which greatly reduces the possibility of the rema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com