A method for producing slag micropowder from copper smelting secondary slag

A technology of slag micropowder and secondary slag, applied in cement production and other directions, can solve problems such as large differences and non-compliance with requirements, and achieve the effects of reducing grinding energy consumption, increasing environmental protection benefits, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

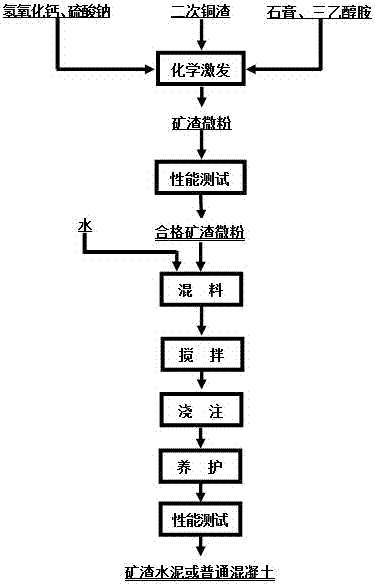

Method used

Image

Examples

Embodiment 1

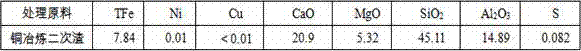

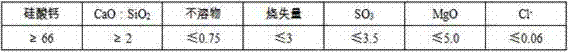

[0036] A method for producing slag micropowder from copper smelting secondary slag. The technological process is as follows: the copper smelting secondary slag produced after high-temperature melting, water quenching and rapid cooling granulation, and grinding and magnetic separation to extract iron is naturally dried in the sun to make it After the water content is less than 10%, put it into the oven for drying. The oven temperature is 100°C. After drying, the water content of the copper smelting secondary slag is ≤1%. The dried copper smelting secondary slag is metered and loaded into the grinding equipment for crushing, and finely ground in a ball mill. The amount of grinding aid triethanolamine added is 0.05% of the mass of the dried copper smelting secondary slag. The addition of chemical activator desulfurization gypsum is 4% of the quality of the copper smelting secondary slag after drying, the addition of sodium sulfate is 2% of the quality of the copper smelting second...

Embodiment 2

[0039] A method for producing slag micropowder from copper smelting secondary slag. The technological process is as follows: the copper smelting secondary slag produced after high-temperature melting, water quenching and rapid cooling granulation, and grinding and magnetic separation to extract iron is naturally dried in the sun to make it After the water content is less than 10%, put it into the oven for drying. The oven temperature is 110°C. After drying, the water content of the copper smelting secondary slag is ≤1%. The dried copper smelting secondary slag is metered and loaded into the grinding equipment for crushing, and finely ground in a ball mill. The addition amount of the grinding aid triethanolamine is 0.1% of the mass of the dried copper smelting secondary slag. The addition amount of chemical activator desulfurization gypsum is 5% of the quality of the copper smelting secondary slag after drying, the addition amount of sodium sulfate is 3% of the copper smelting s...

Embodiment 3

[0042] A method for producing slag micropowder from copper smelting secondary slag. The technological process is as follows: the copper smelting secondary slag produced after high-temperature melting, water quenching and rapid cooling granulation, and grinding and magnetic separation to extract iron is naturally dried in the sun to make it After the water content is less than 10%, put it into the oven for drying, the oven temperature is 120°C, and the water content of the copper smelting secondary slag after drying is ≤1%. The dried copper smelting secondary slag is metered and put into the grinding equipment for pulverization, and finely ground in a ball mill. The addition amount of the grinding aid triethanolamine is 0.15% of the mass of the dried copper smelting secondary slag. The amount of chemical activator gypsum added is 6% of the mass of the dried copper smelting secondary slag, sodium sulfate can be replaced by Glauber's salt, and the added amount of Glauber's salt is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com