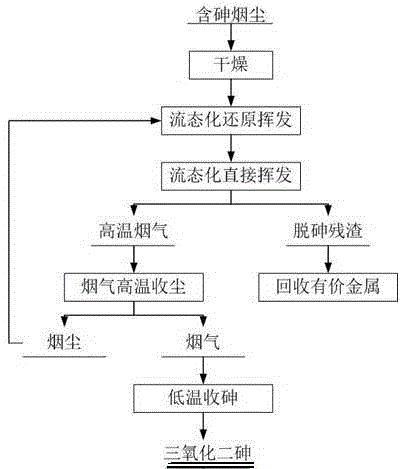

A method for fluidized arsenic removal of arsenic-containing smoke and dust

A technology of arsenic fume and fluidization, which is applied in the direction of improving process efficiency, etc., to achieve the effect of simple process, environmental friendliness and high efficiency of arsenic removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The main components of arsenic-containing smoke and dust are as follows: As 15.78%, Sb 64.23%, Pb 0.78%, Bi0.62%; carbon monoxide gas, of which CO content ≥ 99% by volume. Industrial nitrogen, where N 2 The volume percentage content is ≥99%.

[0036] After drying 1000g of the above-mentioned arsenic-containing dust at 100°C for 2 hours, it is fluidized by a mixed gas of carbon monoxide and industrial nitrogen (the volume ratio of carbon monoxide and industrial nitrogen is 0.05:100), and it is kept at 450°C for 10 minutes, and then the carbon monoxide is removed. Introduce, only use industrial nitrogen to maintain the fluidization of arsenic-containing fumes, and increase the temperature to 500°C, keep warm for 60 minutes, and obtain 784.6g of residue after volatilization, the main chemical components are As 0.43%, Sb 81.36%, Pb 0.87% in mass percentage , Bi0.58%, the arsenic removal rate reaches 97.84%; after the flue gas is cooled to collect arsenic, 206.5g of soot is...

Embodiment 2

[0038] The main components of a certain arsenic-containing smoke are: As 30.54%, Sb 24.32%, Pb 4.2%, Bi 4.1%, Cu 5.66%; hydrogen, of which H 2 The volume percentage content is ≥99%. Industrial argon, in which the content of Ar is ≥99% by volume.

[0039]After drying 1000g of the above-mentioned arsenic-containing dust at 80°C for 3 hours, it is fluidized by a mixed gas of hydrogen and industrial argon (the volume ratio of hydrogen and industrial argon is 0.5:100), and it is kept at 380°C for 25 minutes, and then canceled The introduction of hydrogen, the fluidization of arsenic-containing smoke and dust is only maintained by industrial argon, and the temperature is increased to 600 ° C, kept for 120 minutes, and 563.13 g of volatilized residue is obtained. The main chemical components are As 1.29% by mass percentage, Sb 42.33%, Pb 7.11%, Bi 6.78%, Cu 9.97%, the arsenic removal rate reaches 97.61%; after the flue gas is cooled to collect arsenic, 398.28g of soot is obtained, a...

Embodiment 3

[0041] The main components of a certain arsenic-containing smoke and dust are as follows: As 2.2%, Sb 2.4%, Pb 1.96%, Bi 3.71%, Cu 19.02%; gas, of which H 2 , CO, CH 4 , CO 2 , N 2 The content in volume percentage is 1.8%, 32.4%, 23.6%, 12.4%, 50.1%, respectively. Industrial nitrogen, where N 2 The volume percentage content is ≥99%.

[0042] After drying 1000g of the above-mentioned arsenic-containing dust at 120°C for 8 hours, make it fluidized by a mixed gas of coal gas and industrial nitrogen (the volume ratio of coal gas and industrial argon is 5:100), keep it warm at 480°C for 5 minutes, and then cancel the gas The arsenic-containing fume is kept fluidized only by industrial nitrogen, and the temperature is increased to 550°C, and kept for 90 minutes to obtain a residue after volatilization of 963.74g. The main chemical components are As 0.14% by mass percentage, Sb 2.44%, Pb 2.0 %, Bi 3.78%, Cu19.64%, the arsenic removal rate reached 93.94%; after the flue gas was c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com