Warp-knitting hand sample loom

A small prototype loom, small prototype technology, applied in warp knitting, flat warp knitting machine, knitting and other directions, can solve few problems, achieve the effect of reducing experimental cost, improving design efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

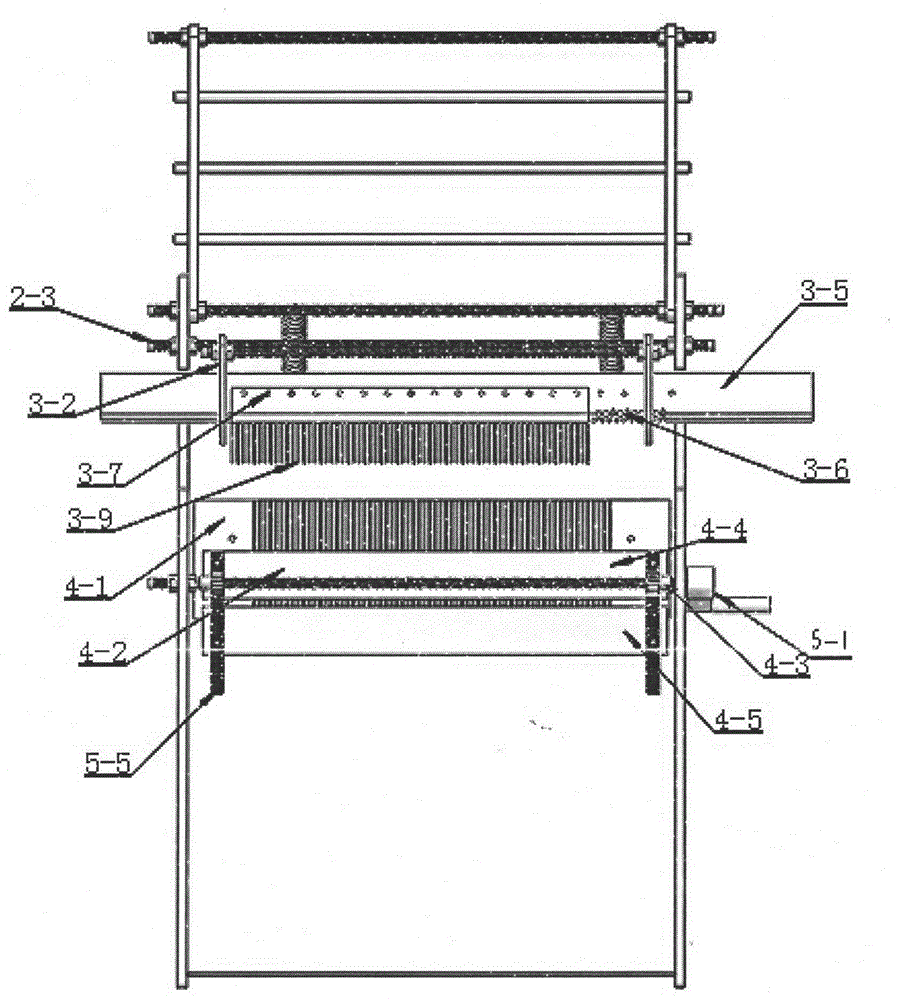

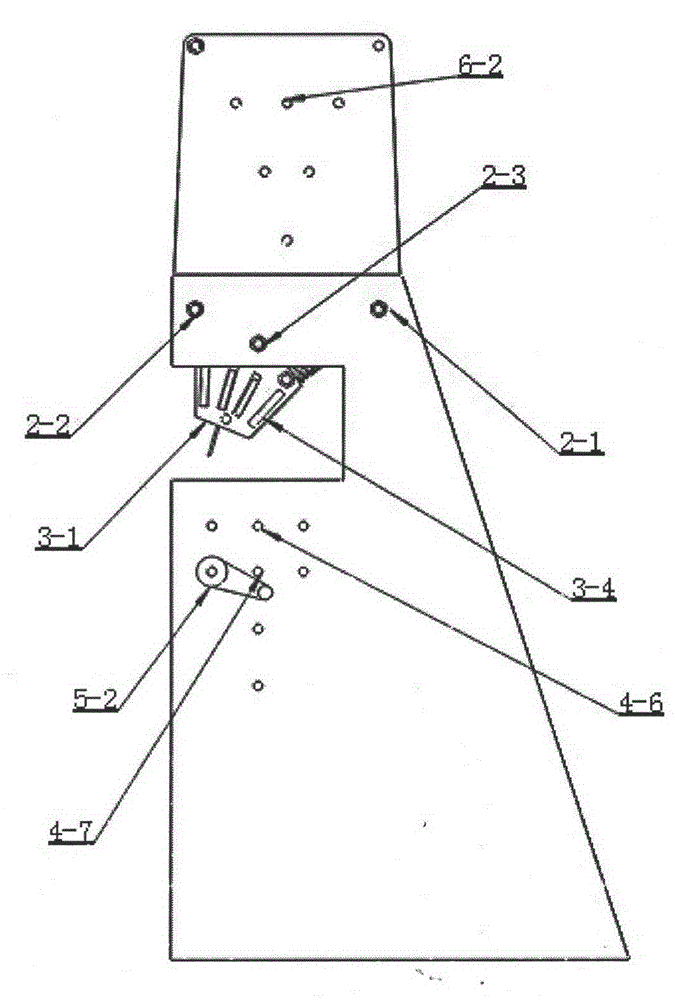

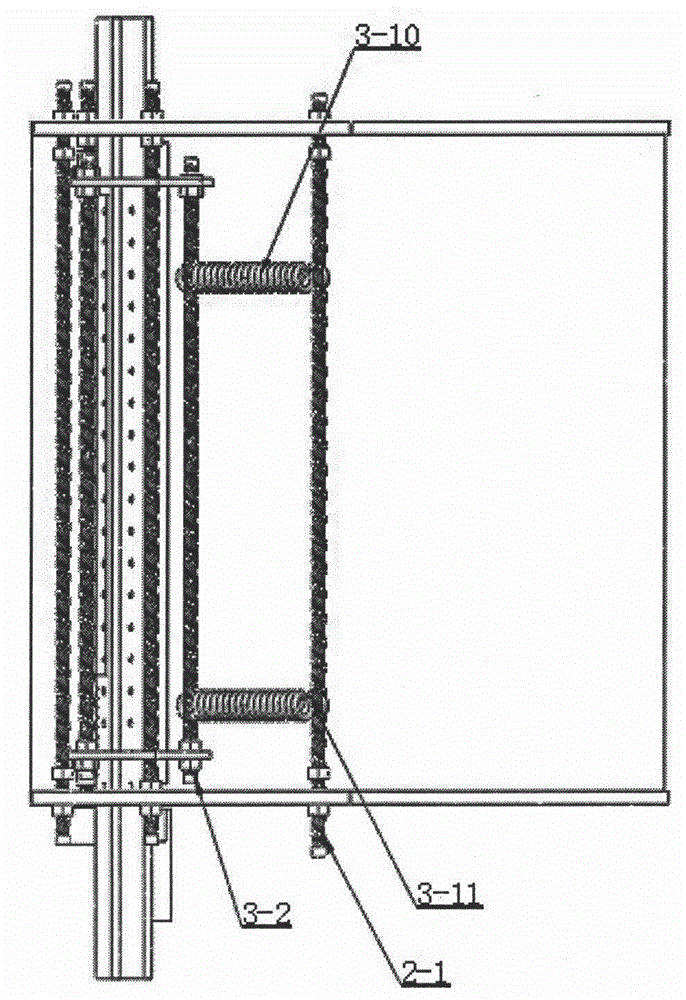

[0030] see Figures 1 to 7A kind of warp knitting sample loom device shown, it comprises: frame 1, and this frame 1 comprises the second wallboard 1-2 of two longitudinal parallel arrangements, the 4th wallboard 1-4, and two longitudinal The bottom plate 1-3 placed horizontally in the middle of the wall panels is arranged in parallel, and the first wall panel 1-1 and the fifth wall panel 1-5, which are fixedly connected to the top of the wall panels Board 1-2, the fourth wallboard 1-4 are fixed, the first bracket 2-1 connected, the second bracket 2-2, the third bracket 2-3 of the bar traversing device fixedly installed, and the described The first wallboard 1-1, the second wallboard 1-2, the base plate 1-3, the fourth wallboard 1-4, the fifth wallboard 1-5 and the first bracket 2-1 fixedly connected to the wallboard, the second Two brackets 2-2 and the third bracket 2-3 jointly constitute a frame structure; mechanism fixing device 2, which includes a first bracket 2-1 and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com