Combined core mold provided with compression-resisting tension bars and used for cast-in-place concrete

A technology of cast-in-place concrete and mandrel, which is applied to building components, floor slabs, buildings, etc. It can solve the problems of easy deformation, unstable size, and poor compression resistance, and achieve the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

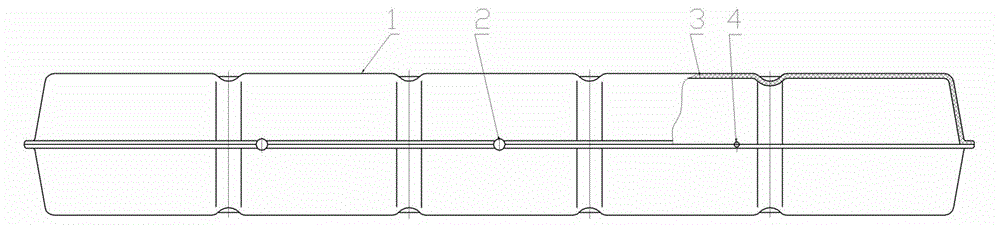

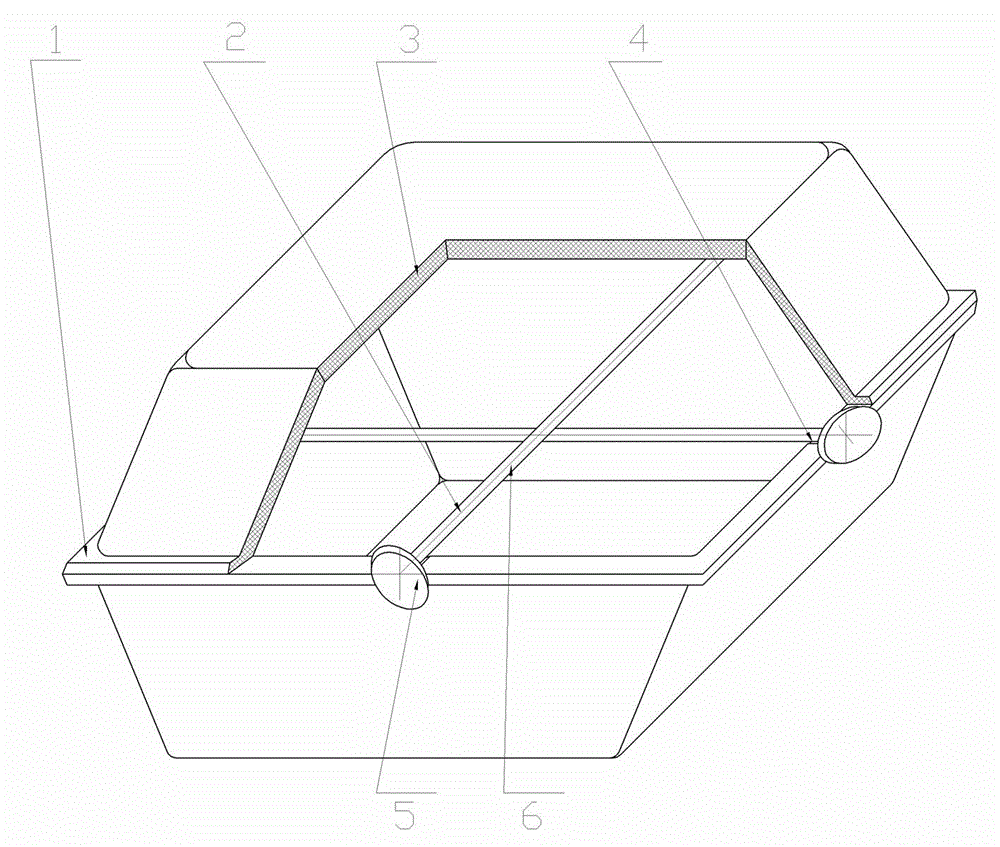

[0014] Embodiment 1, in the present invention, two mold tiles 3 are relatively combined to form a combined core mold 1, and more than one groove 4 is provided on the contact surface of the two mold tiles 3, and the grooves 4 are embedded with anti-corrosion molds penetrating through both sides of the mandrel. The compression strip 2 can effectively prevent the outer edge of the mandrel from opening outwards when the mold tile 3 is under pressure, which greatly increases the strength of the mandrel. refer to Figure 1 to Figure 2 .

Embodiment 2

[0015] Embodiment 2, the shape of the groove 4 opened on the mold tile 3 is semicircular, square or V-shaped, and it can be formed by one-time molding or secondary processing. refer to Figure 1 to Figure 2 , all the other are with embodiment 1.

Embodiment 3

[0016] Embodiment 3, the anti-compression braces 2 are composed of pull rods 6 and pull caps 5, and the distance between the pull caps 5 is the length between the outer frames of the mandrel. refer to Figure 1 to Figure 2 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com