Campshed boring machine

A drilling machine and column technology, which is applied in the field of pile drilling machines, can solve the problems of mud inclusion and poor connectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

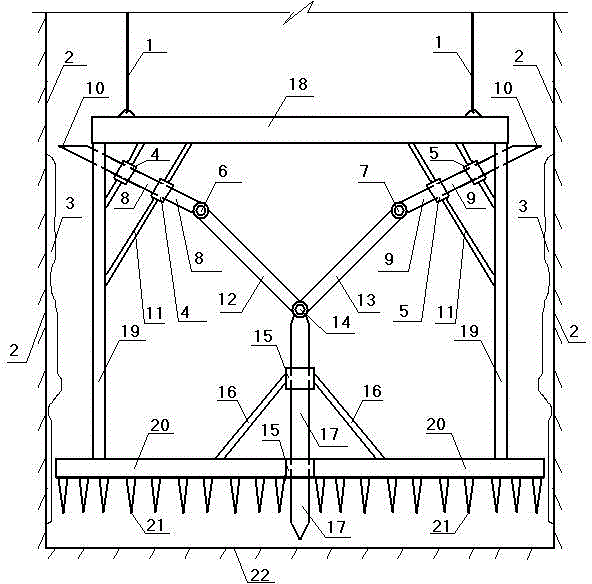

[0011] The accompanying drawing is a specific embodiment of the present invention. In this embodiment, the beam A18, the beam B20, the columns 19 on both sides, and the plurality of punches 21 under the beam B form a heavy-duty punching component. The thimble 17 is located at the middle and lower part, and the thimble It can slide up and down in the two sleeves C15, the lower sleeve C is fixed to the beam B, the upper sleeve C is fixed to the beam B through two connections B16, and the upper end of the thimble hinges the lower end of the strut A12 and the lower end of the strut B13 through the pin C14 , the upper end of the support rod A hinges the right end of the handle A8 through the pin A6, the left end of the handle A is provided with a tip 10, the handle A slides in the two sleeves A4, and the two sleeves A are fixed to the beam A and the beam A through the connection A11 The left column; the upper end of the support rod B13 hinges the left end of the handle B9 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com