Mineral mining equipment with vibration damping

A technology for minerals and equipment, applied in the field of mineral mining equipment, can solve the problems of inability to effectively suppress vibration, frequent replacement of support positions, etc., to avoid the trouble of replacing support positions and frequent alignment, avoid left and right shaking, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

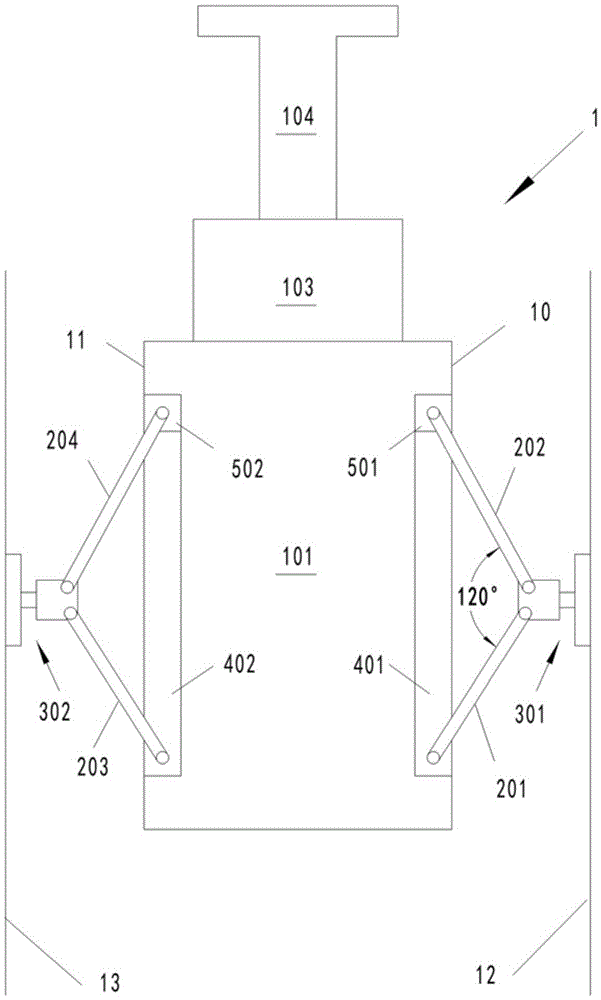

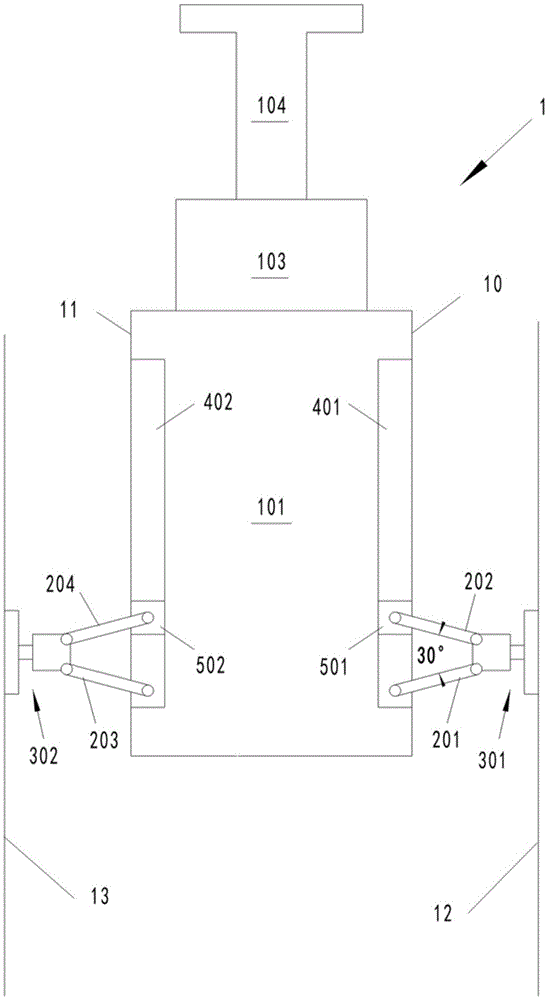

[0022] The following detailed description of the preferred embodiments of the invention with reference to the accompanying drawings is merely exemplary in nature and is not intended to limit the invention, its application or uses. It should be noted that although the technical scheme of the present invention has been described in conjunction with the fully mechanized excavator in the preferred embodiment, it will be easily understood by those skilled in the art that the scope of protection of the present invention is obviously not limited to fully mechanized excavators, without departing from Under the condition of the basic principles of the present invention, those skilled in the art can apply the technical solution of the present invention to other mineral mining equipment, and such changes will also fall within the protection scope of the present invention.

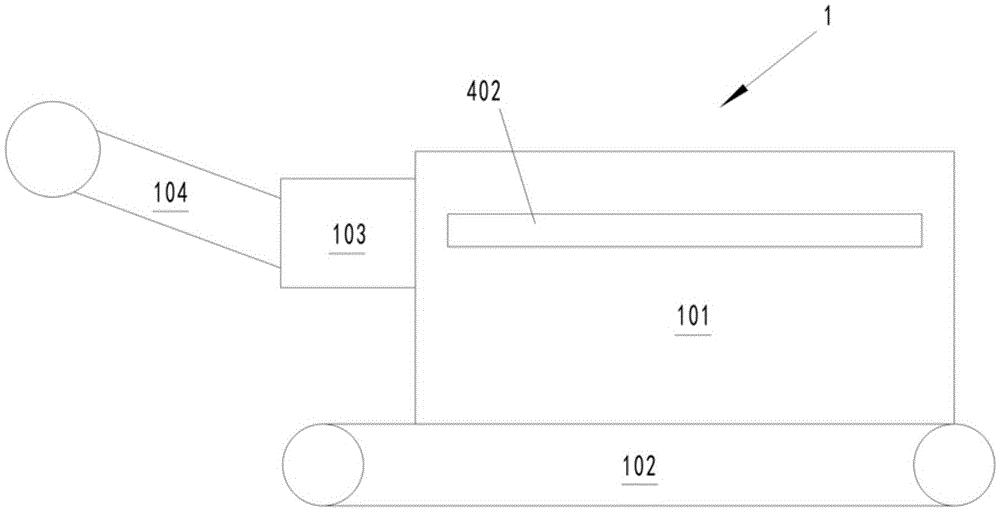

[0023] First refer to figure 1 , which shows a fully mechanized excavator 1 provided with a vibration damping devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com