A kind of oil leaf bearing

A bearing and oil blade technology, applied in the field of bearings, can solve the problems of poor stability and poor economy of the bearing system, and achieve the effects of reducing operating costs, reducing processing difficulty and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

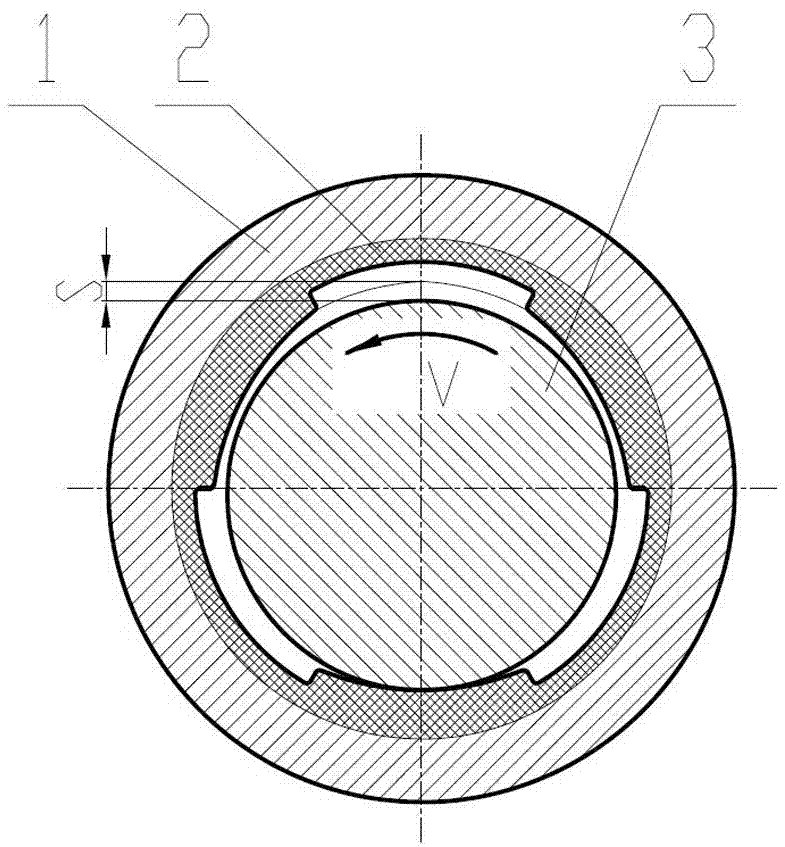

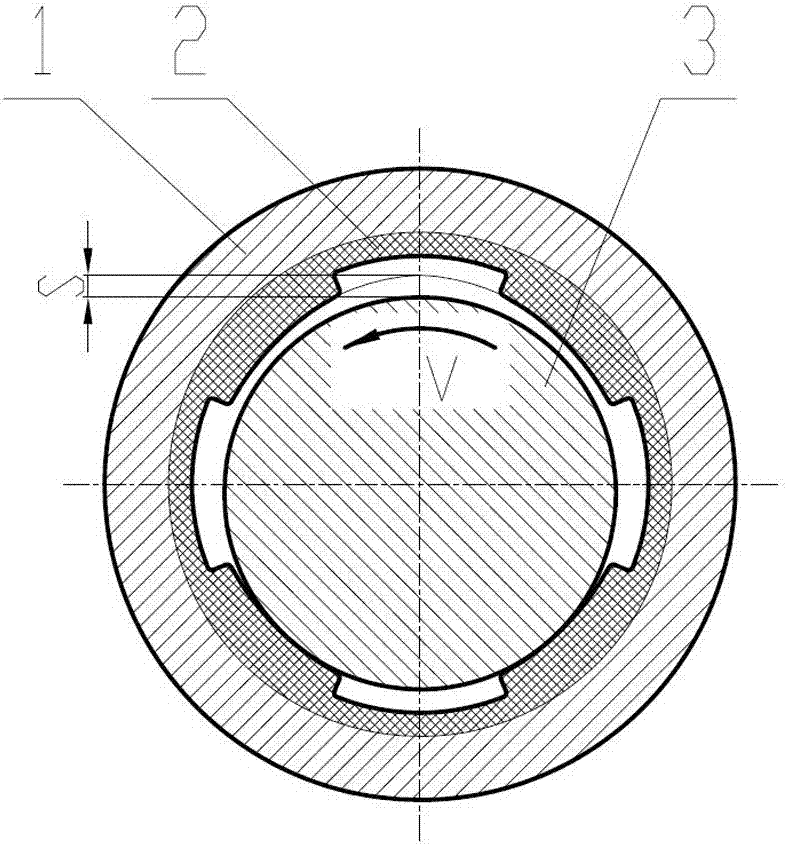

[0023] Embodiment 1, taking the four-lobe bearing with the bearing body 1 as a complete ring structure as an example, the details are as follows:

[0024] see Figure 5 , the oil leaf bearing includes a bearing body 1, a Ujin tile 2 and a Ujin tile support slider 4, and the Ujin tile 2 is poured on the Ujin tile support slider 4 to form an integral structure, and the profile line of the working surface is a leaf shape. The bearing body 1 is a ring-shaped structure, and its inner wall is provided with 4 circumferentially distributed radial bottomed chutes, and each chute is equipped with a Ujin tile support slider 4 that has been poured with Ujin tile 2, which can be placed in the chute. slide. The Wujin tile 2 on the slider 4 faces the center of the bearing circle, and there are screw holes and fastening bolts 6 on the back of the slider 4; corresponding bolt holes are opened at the bottom of the chute of the bearing body, and the fastening bolts 6 run through the Bolt holes...

Embodiment 2

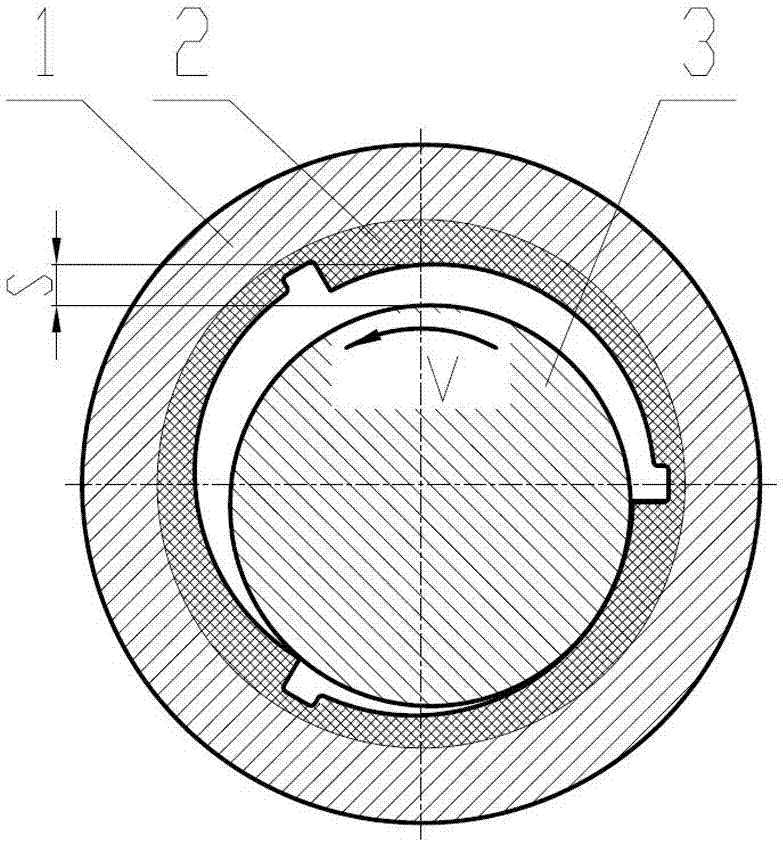

[0025] In the second embodiment, a four-lobe bearing with two halves of the bearing body 1 is taken as an example.

[0026] see Figure 6 , The oil leaf bearing includes a bearing body 1, a Ujin tile 2 and a Ujin tile support slider 4, and its specific structure is similar to Embodiment 1. However, in order to further facilitate bearing processing, disassembly, and maintenance, the bearing body 1 adopts a split structure, which is divided into two halves, the lower half bearing body 1-1 and the upper half bearing body 1-2. 8 Tighten it into one piece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com